RESOURCES

Home » SMTCL invites you to join us at the 22nd China International Manufacturing Expo

SMTCL invites you to join us at the 22nd China International Manufacturing Expo

Table of Contents

On September 1st, the 22nd China International Equipment Manufacturing Expo (CIEME 2024) will grandly open at the Shenyang International Exhibition Center. Shenyang Machine Tool Co., Ltd. will showcase 6 high-end machines and 5 functional components, fully demonstrating the company’s latest innovations and developments.

This year’s expo will be held both online and offline. The offline exhibition will take place from September 1st to 4th at the Shenyang International Exhibition Center, while the online event will run from September 1st to October 30th. We sincerely invite all customers, industry professionals, and machinery enthusiasts to visit the Shenyang Machine Tool booth for discussions and collaboration.

Exhibit Machine Introduction

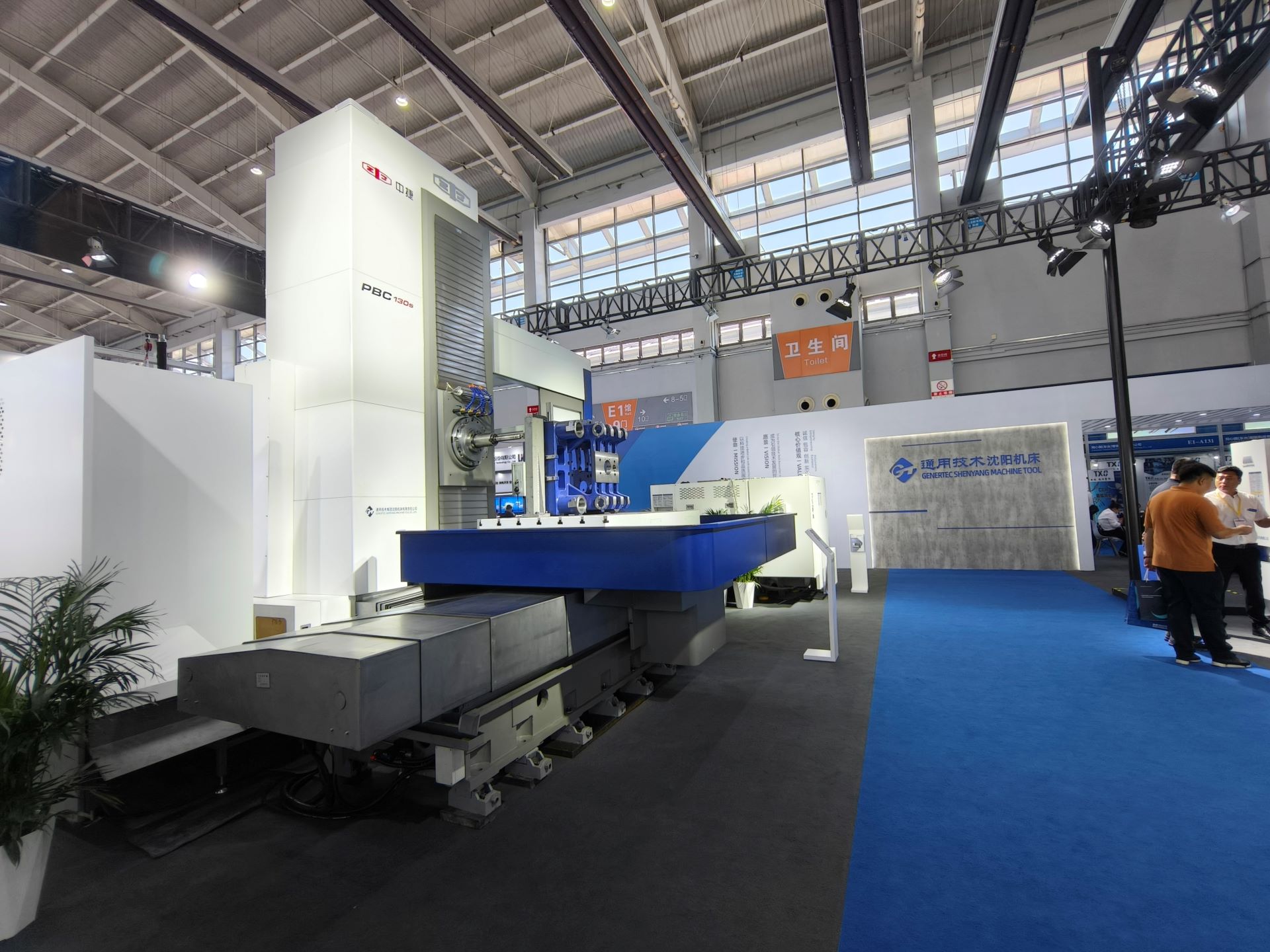

1.PBC130s CNC Horizontal Milling/Boring Machine

The machine is equipped with three-axis full steel hard rails, providing stable operation, high precision, and strong rigidity due to the rolling-sliding composite rail pairs. The Y-axis uses a counterweight-free design, ensuring fast response speed and smooth operation. The boring spindle (W-axis) can be equipped with a magnetic scale to achieve full closed-loop control.

This product is widely used in industries such as transportation, energy, metallurgy, construction machinery, pumps and valves, and molds. It is the preferred equipment for key processes in machining box-type, shell-type, and base-type components.

2.HTC63Qm/3000 Horizontal Turning Center

The product is mainly used for processing various shafts and discs, capable of turning various threads, arcs, tapers, and inner and outer curved surfaces of rotating bodies. It meets the high-speed cutting requirements of both ferrous and non-ferrous metals, making it ideal for efficient, high-volume, and high-precision processing of rotating parts in industries such as automotive, motorcycle, and electronics.

3.HTC30Hm Automated Machining Unit

The automation unit greatly reduces labor costs and increases production efficiency, making it especially suitable for high-precision batch processing of small to medium-sized parts.

Primarily used in the automotive and bearing industries, it is capable of turning shaft and disc-type parts, including threads, arcs, cones, and external and internal curves, as well as integrated drilling, milling, and tapping, enhancing machining efficiency.

4.HTC40Hm/500 Horizontal Turning Center

Additionally, it can be fitted with a servo tailstock module, allowing high-speed operation without collision and with intelligent adjustment of tailstock force. The machine boasts high machining accuracy and stability, making it suitable for industries such as automotive, electronics, and non-ferrous metal processing, and is ideal for machining parts like differentials, gears, guide sleeves, and flanges.

5.HMC63Q Horizontal Machining Center

It is suitable for industries such as automotive parts and pumps and valves, and can meet the high-efficiency processing needs of single or small batch production.

6.iV85 Vertical Machining Center

The machine is primarily used for processing parts in the automotive, motorcycle, and agricultural machinery industries, meeting the demands for efficient and large-scale machining.

7.HFD Vertical and Horizontal Swivel Head

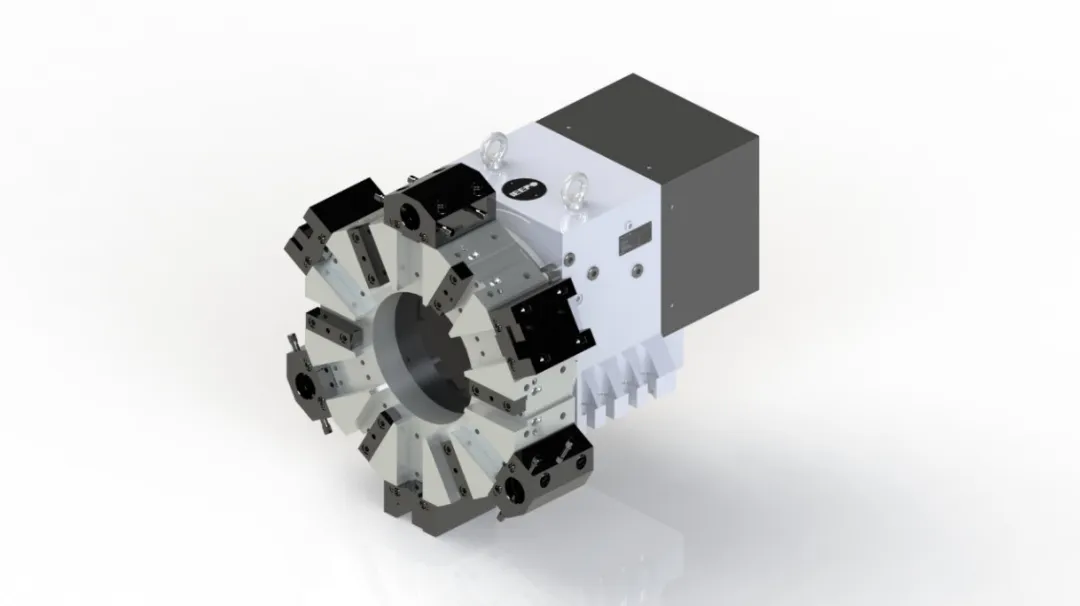

8.T342S-PSC Automatic Tool Change Power Turret

This product is used in horizontal lathes and vertical turning and milling centers, significantly improving automation and flexibility in production lines, overcoming limitations on the number of tools, and providing clear advantages in complex and multi-stage integrated machining processes.

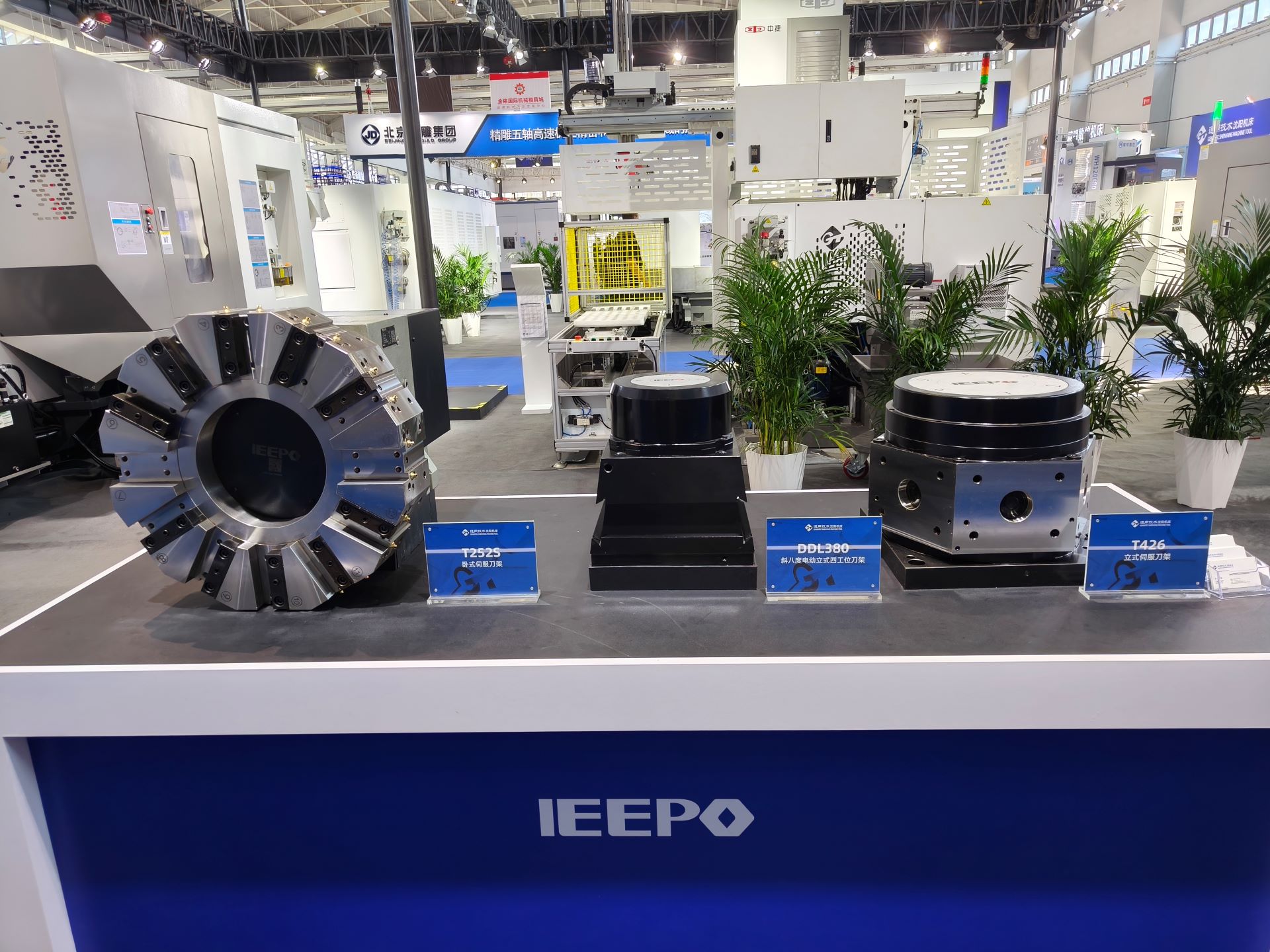

9.T426 Vertical Servo Turret

10.T252S Horizontal Servo Turret

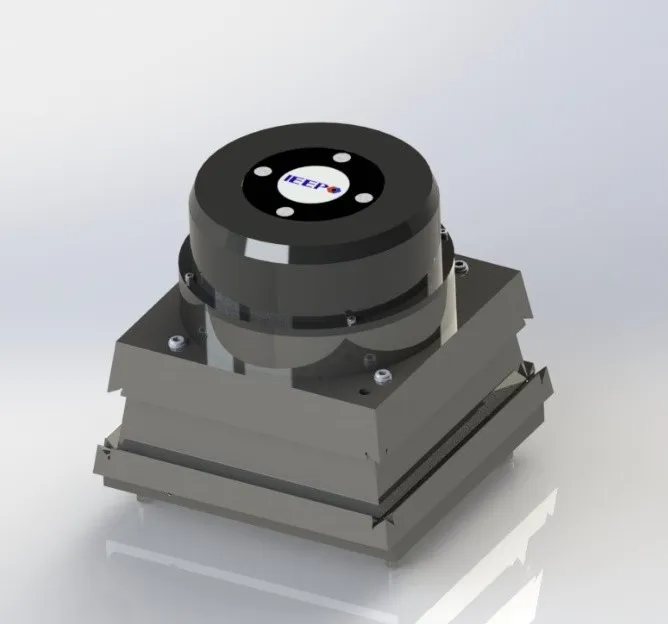

11.DDL380 Electric Vertical Four-Position Turret