Guarantee

Foundry

Pouring the molten metal into the molds to form the initial structural parts of the machine tool.

Painting

Painting the machine tool to protect its surface and enhance its appearance.

Rough Machining

Performing initial machining on the cast parts to remove excess material and roughly shape the parts.

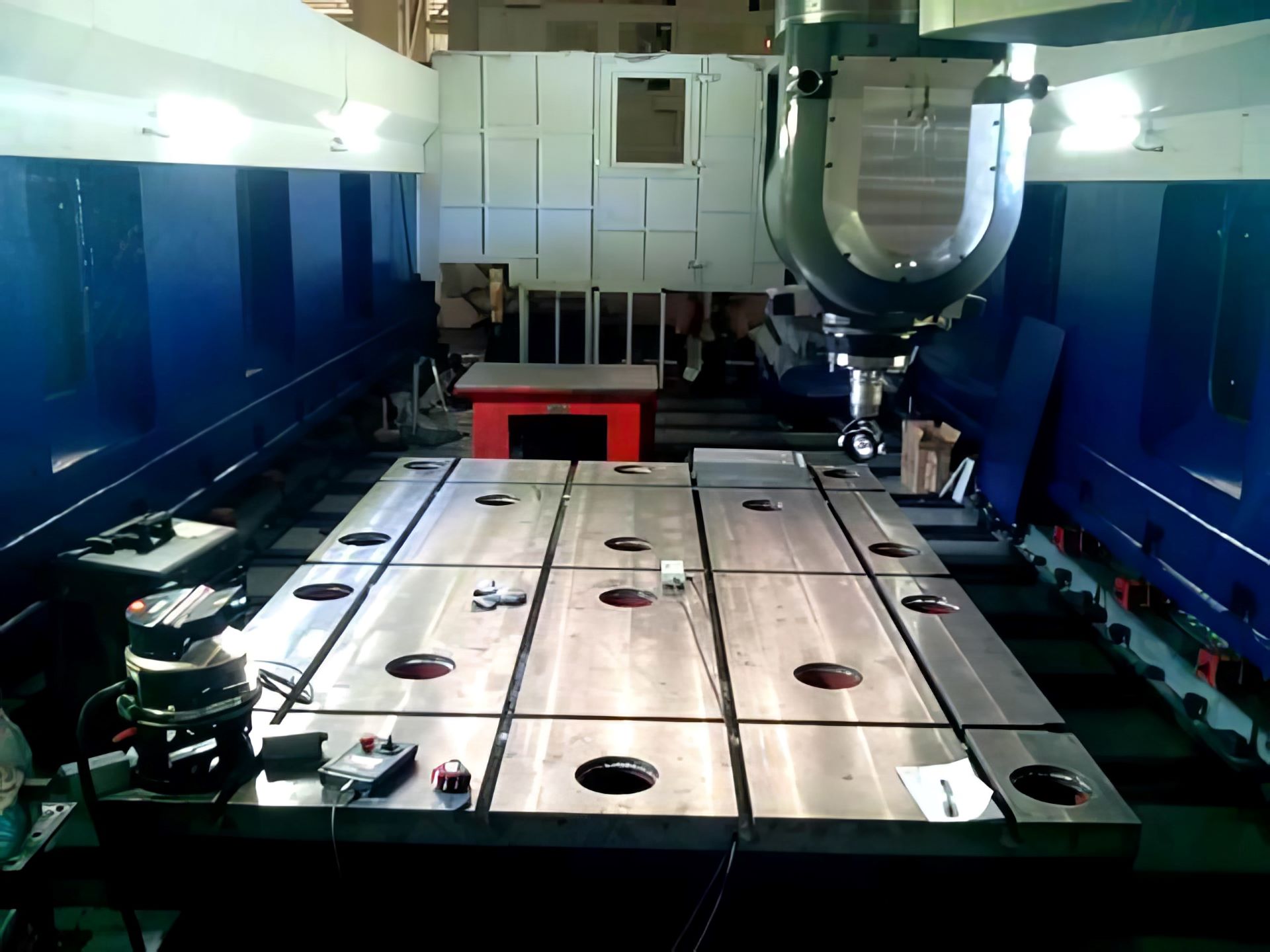

Precision Machining

Finely machining the rough-machined parts to achieve the design's dimensional accuracy and surface quality requirements.

Parts Preparation

Preparing the machined parts and other standard components (such as bolts, nuts, etc.).

Initial Assembly

Assembling the machine tool according to the design drawings.

Adjustment and Calibration

Adjusting and calibrating the assembled machine tool to ensure the proper fit and movement precision of its components.

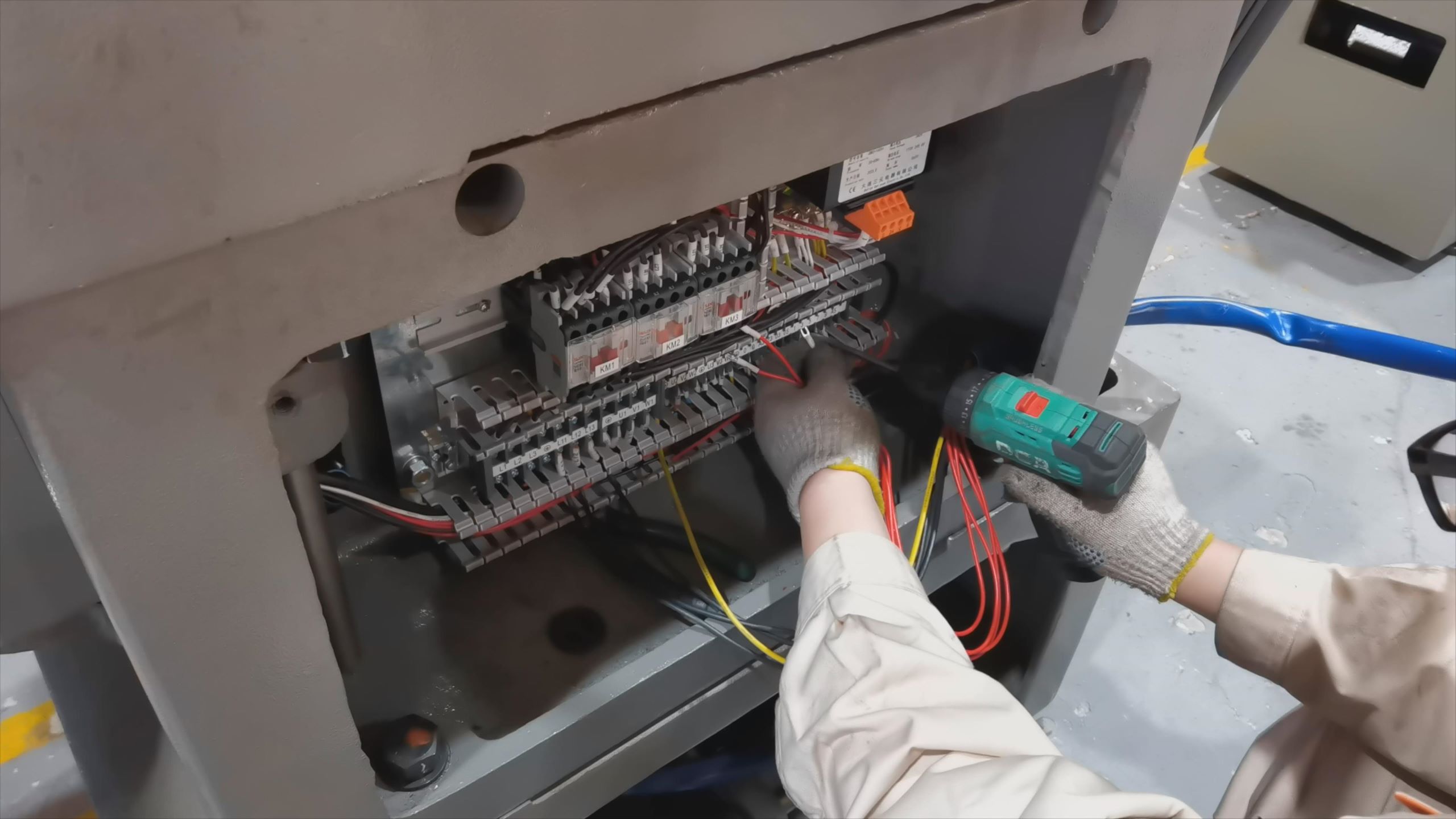

Installation of Electrical Components

Installing motors, controllers, sensors, and other electrical components.

Performance Testing

Testing the machine tool's working performance and stability under simulated working loads.

Troubleshooting

Identifying and resolving issues that arise during testing.

Packaging

Packaging the machine tool for shipment.

Delivery

Transporting the machine tool to the customer's specified location.

Energy Consumption and Power Testing

Spatial Error

Whole Machine Modal Testing

Free Modal Analysis

Straightness Measurement Device

Coordinate Measuring Machine

Cylindricity Measuring Machine

30-ton Tensile Testing Machine

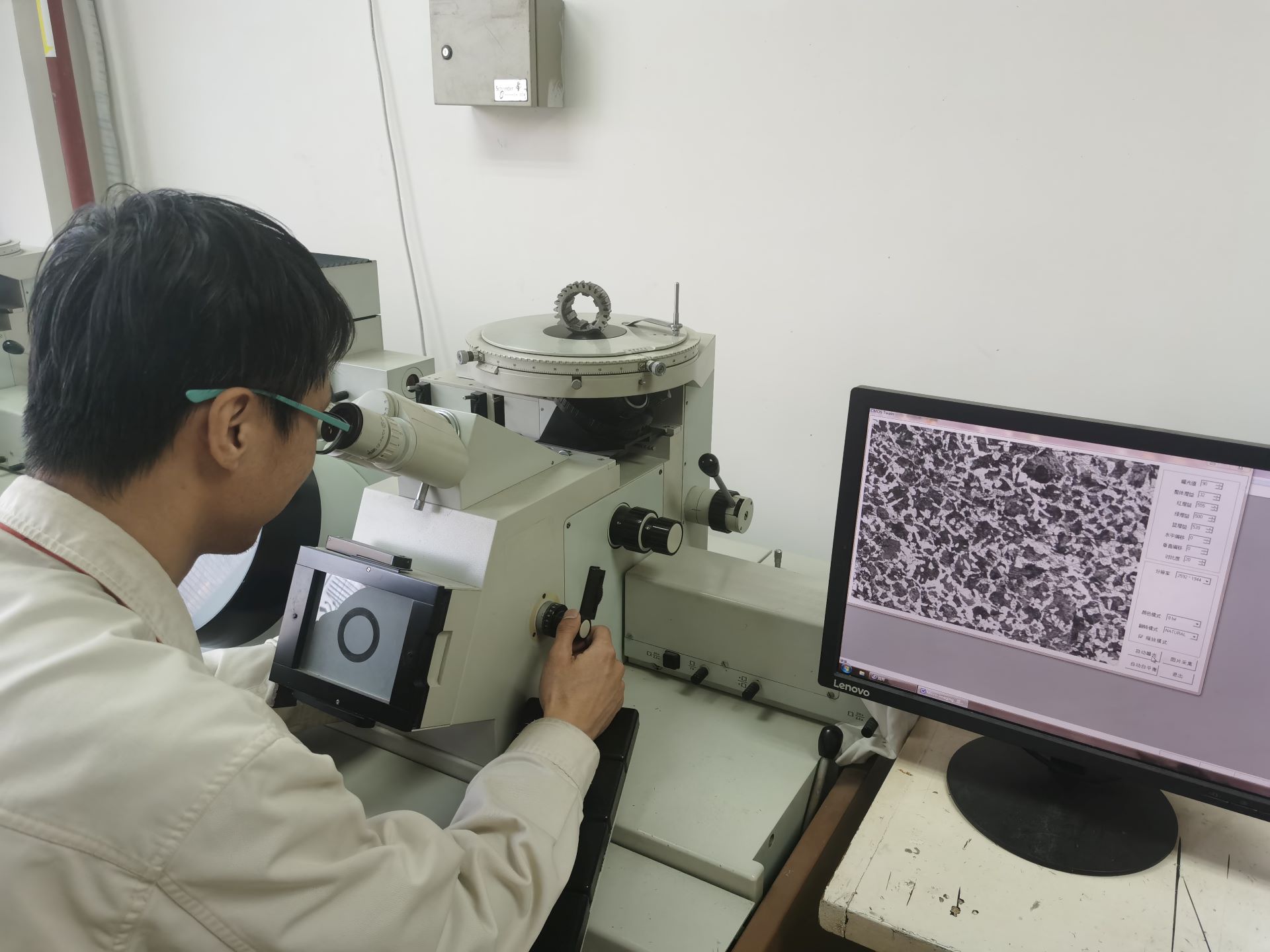

Machine Part Metallographic Inspection and Analysis

Constant Temperature and Humidity Chamber

Various Hardness Testers

Photodiode Array Spectrometer

UV Aging Test Chamber

Kinematic Viscometer

Cutting Fluid Analysis