RESOURCES

Home » SMTCL Hybrid Electric Vehicle (HEV) Crankshaft Production Line Processing Demonstration

SMTCL Hybrid Electric Vehicle (HEV) Crankshaft Production Line Processing Demonstration

Table of Contents

Hybrid Electric Vehicle (HEV) Crankshaft Machining Production Line Live Replay

1.CNC Crankshaft Milling Machine SUC500DEM4

The HMC50Q Horizontal Machining Center is a high-precision horizontal machining center designed for efficient crankshaft processing. Equipped with a specialized hydraulic fixture, it enables multi-process machining in a single setup. Its high automation level is achieved through a rotating table with a central control oil passage and a six-position hydraulic fixture, allowing for automatic loading, unloading, and intelligent posture detection of the workpiece. It features a powerful cooling system, including 2MPa internal coolant spray through the spindle, perimeter spindle spray, and a high-flow 130L/min overhead spray, ensuring effective cooling of the spindle tool, workpiece, and efficient chip removal.

2.SUC500DHT5 Dual-Spindle Horizontal CNC Lathe

The SUC500DHT5 Dual-Spindle Horizontal CNC Lathe is a high-precision, flexible, and efficient CNC machine tailored for crankshaft main journal machining in the automotive industry. It features a hydraulic floating rear-pull chuck for automatic positioning and clamping of the crankshaft, with dual tool turrets processing simultaneously to maximize efficiency. Both rough and finish machining of the crankshaft main journal are performed through "turning" operations. The machine bed is inclined at a 45° angle to enhance chip evacuation, and its compact footprint minimizes space costs and allows for versatile machine layout options.

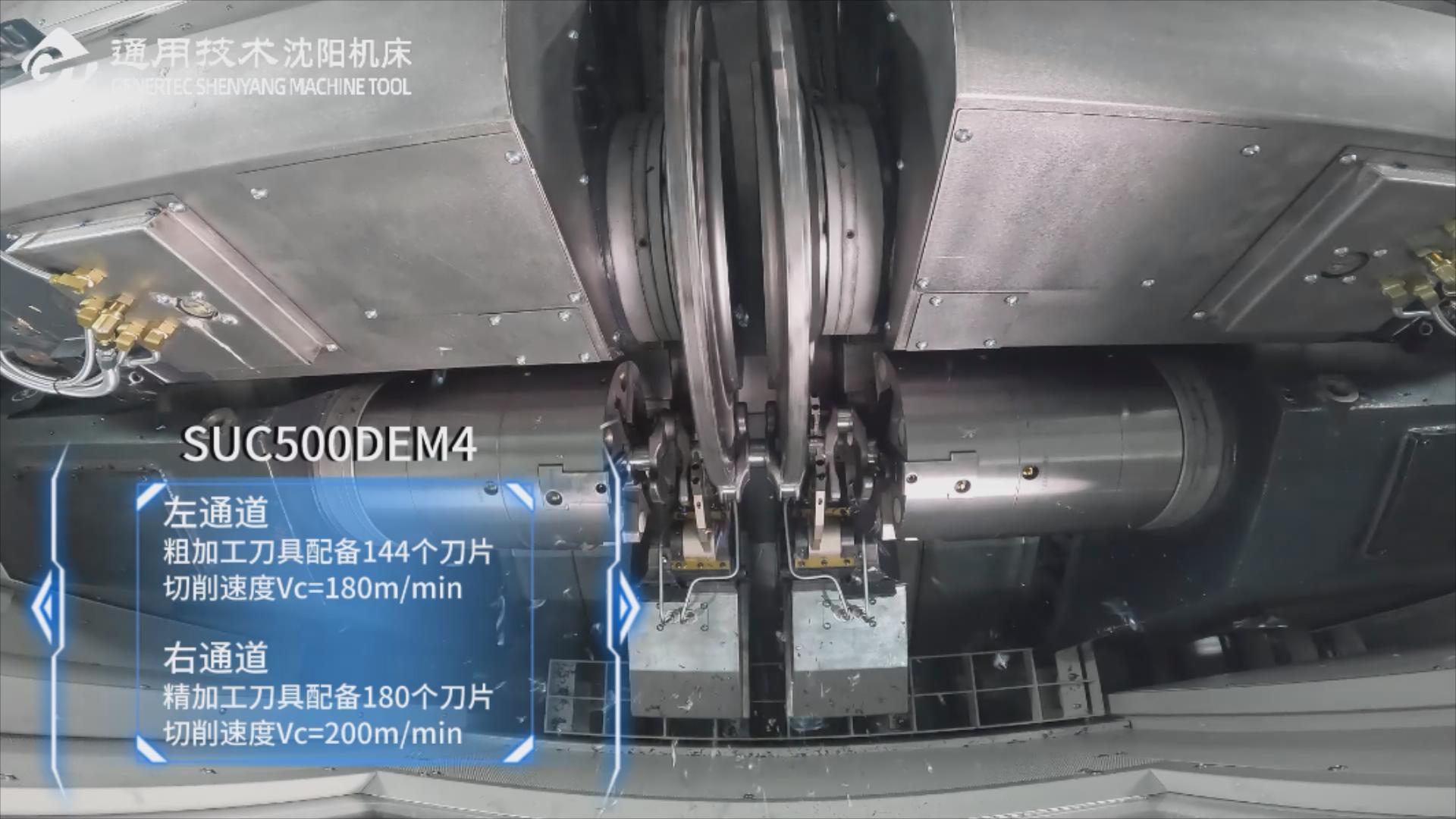

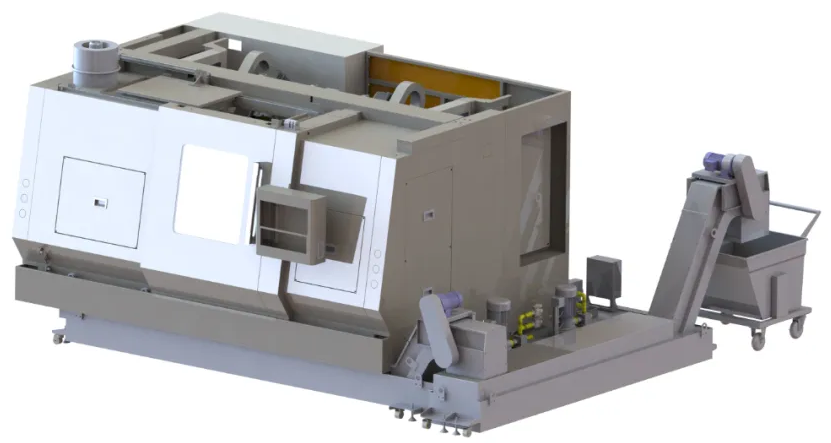

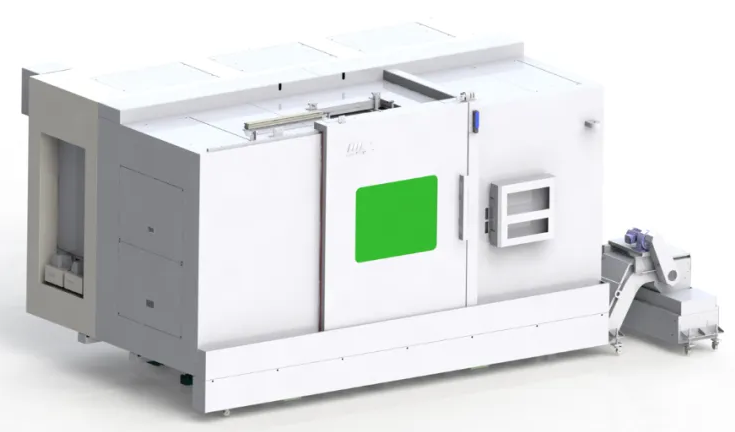

3.SUC500DEM4 High-Speed External Milling Machine

The SUC500DEM4 High-Speed External Milling Machine is a high-precision, flexible, and efficient specialized machine for crankshaft machining. It utilizes carbide-formed high-speed external milling cutters, with dual milling heads operating simultaneously to achieve single-pass forming for high processing efficiency. Equipped with a specialized hydraulic self-centering chuck, it ensures automatic positioning and clamping, allowing for precise and efficient milling of both crankshaft rod journals and main journals. The machine bed is designed with a steep incline to optimize chip evacuation performance.

Hybrid Electric Vehicle (HEV) Crankshaft Production Line Processing Demonstration

Need help finding a machine?

We will gladly assist you in making the right decision to achieve your business goals

Get a free Consultation