Home » Products » ACCESSORIES » Machine Tool Spare Parts » CA Series Ball and Roller Bearings

CA Series Ball and Roller Bearings

Maintenance and Adjustment of The Machine

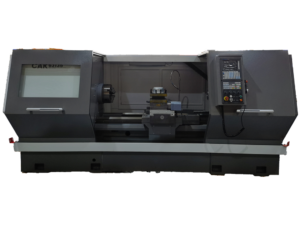

Accuracy of the machine affects turning quality directly and clearance of the machine can directly affect the accuracy of the machine. Except those, adjustment of some mechanism of the machine relates to production efficiency and operating safety, therefore, in order to guarantee turning quality and operating safety to raise production efficiency, operator should master the adjusting methods of clearance and other mechanism of the machine.

Home » Products » ACCESSORIES » Machine Tool Spare Parts » CA Series Ball and Roller Bearings

Contact

Wide Product Portfolio

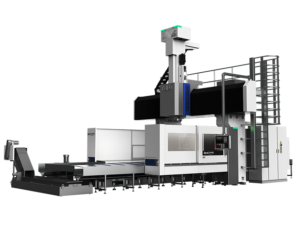

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

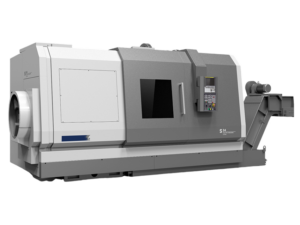

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

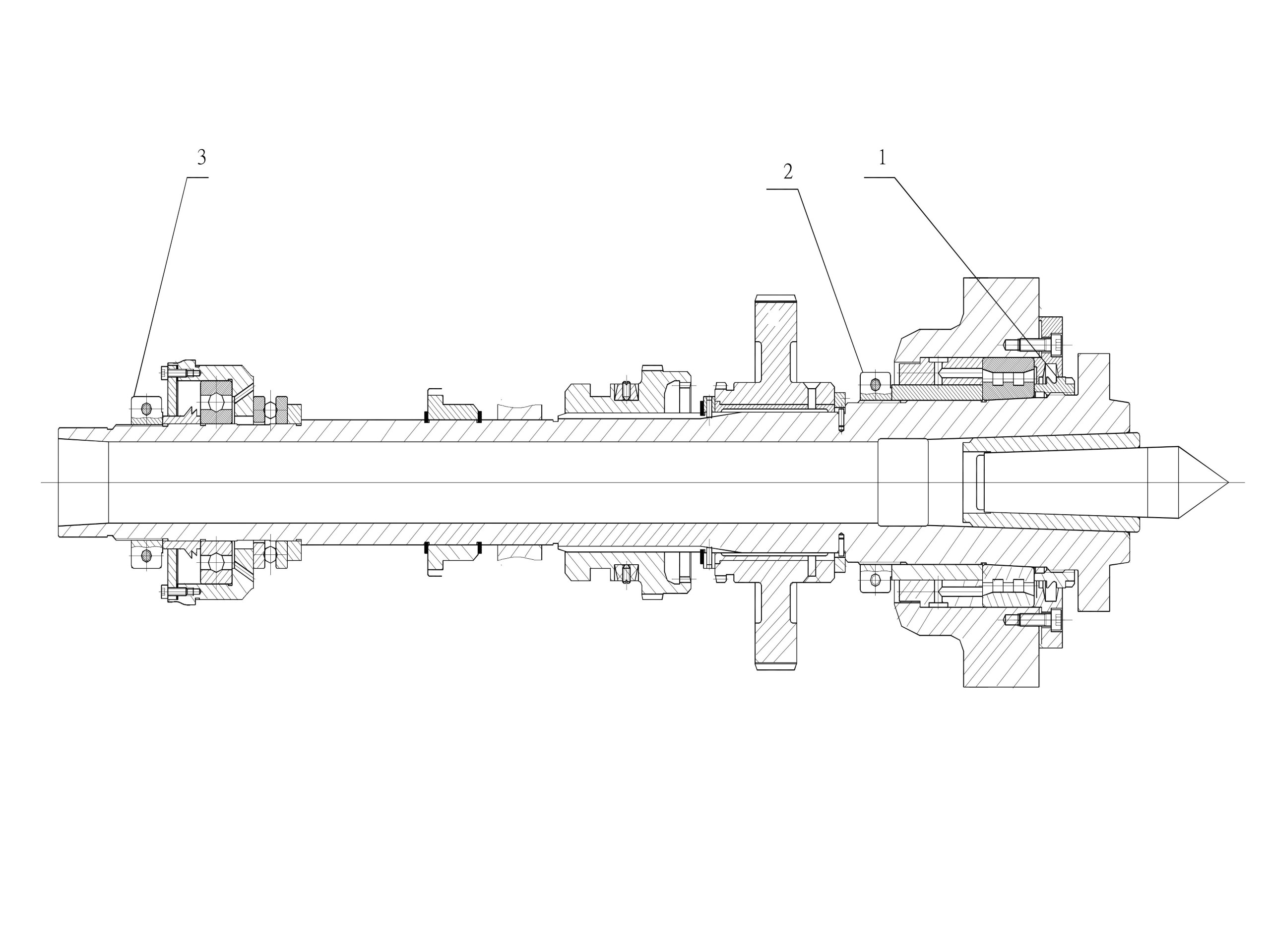

Excessive clearance in spindle bearings directly effects turning accuracy. The rotating accuracy of the spindle includes two kinds, i.e. run-out and axial slip of it. Run-out of the spindle is guaranteed by two double row roller bearings at the front of spindle while axial slip by single row ball thrust bearing at the rear of spindle. Check method is according to items 5 and 8 in the TEST CERTIFICATE. If the readings exceed the permissible error, in most cases, it is enough to adjust two bearing only. The adjusting method is as follows: Loosen the looking screw on the nut 1(Fig. 12) or the nut 2. After adjustment retighten the locking screws. In case of failure after several trails, adjust rear bearing by the same method as described above. After that, run the spindle idle at high speed for an hour and observe the bearing temperature should not exceed 70° C. If it is exceed, first loosen lock the screws on set nuts (2) and 1, then the nuts (2) and (1) should slight loosened, after the adjustment, retighten the lock screws.

Fig.1 Spindle Structure

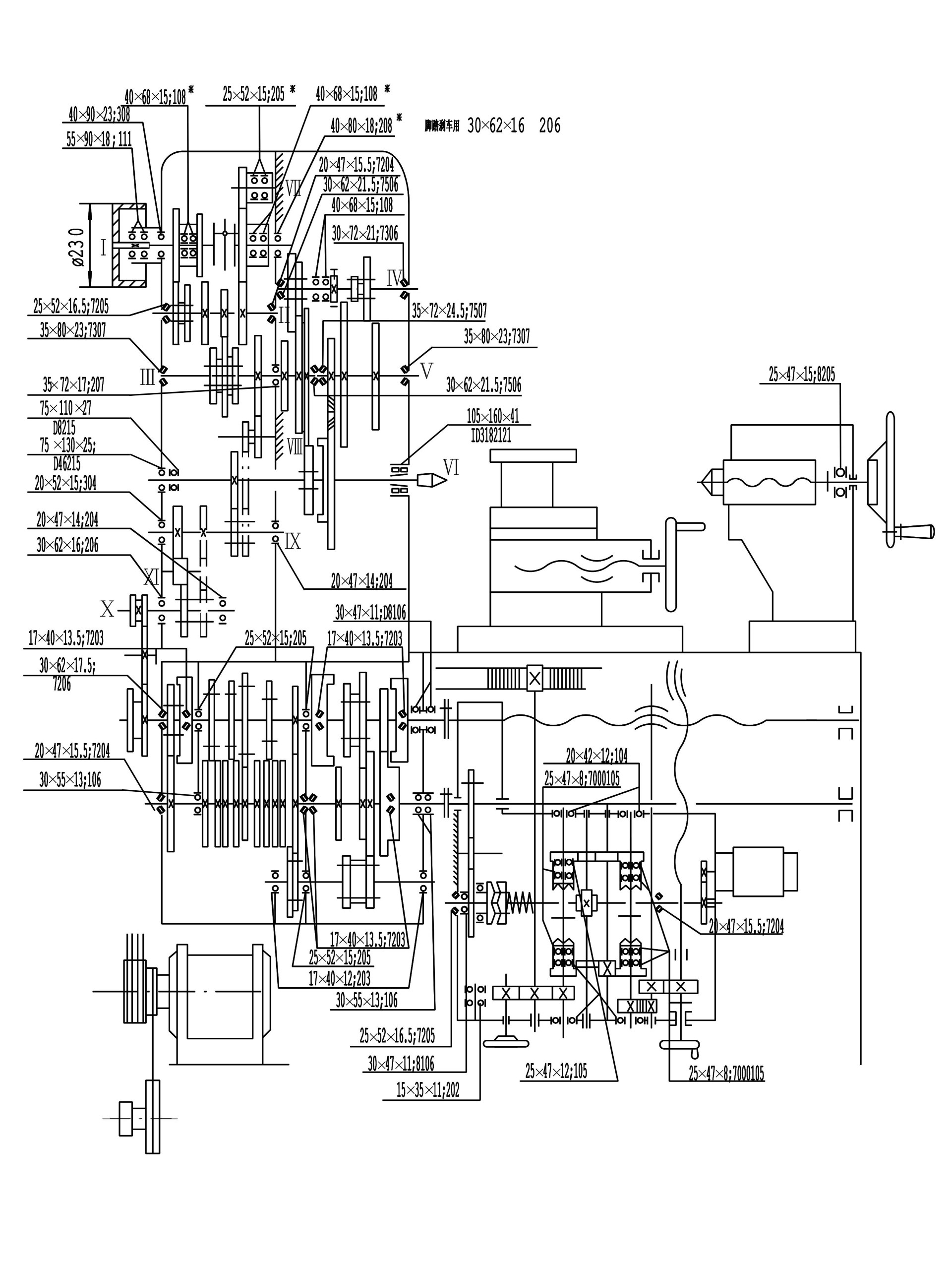

Notice: The machine with foot-pedal braking device is not provided with bearing marked by symbol ※.

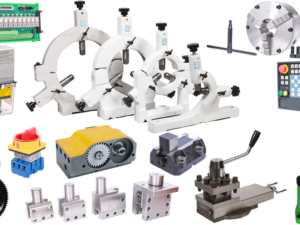

| Code of Bearing | Accuracy Class | Main Size | Qty. | Location Mounted | Remarks | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Single row radial ball bearing | ||||||||||

| 104 | G | 20x42x12 | 2 | Apron | ||||||

| 105 | G | 25x47x12 | 4 | |||||||

| 106 | G | 30x55x13 | 3 | Feed box | ||||||

| 108 | G | 40x68x15 | 6 | Headstock | Two pcs are used for the machine with foot pedal braking device | |||||

| 111 | G | 55x90x18 | 2 | Headstock | ||||||

| 202 | G | 15x35x11 | 2 | Apron | Mounted in cam | |||||

| 203 | G | 17x40x12 | 2 | Feed box | ||||||

| 204 | G | 20x47x14 | 2 | Headstock | ||||||

| 205 | G | 25x52x15 | 2 | For the machine with hand braking device | ||||||

| 205 | G | 25x52x15 | 3 | Feed box | ||||||

| 206 | G | 30x62x16 | 1 | Headstock | For the machine with foot pedal braking device | |||||

| 207 | G | 35x72x17 | 1 | |||||||

| 208 | G | 40x80x18 | 1 | For the machine with hand-braking | ||||||

| 304 | G | 20x52x15 | 1 | |||||||

| 308 | G | 40x90x23 | 1 | |||||||

| 7000105 | G | 25x47x8 | 6 | Apron | ||||||

| Single row taper roller bearing | ||||||||||

| 7203 | G | 17x40x13.5 | 6 | Feed box | ||||||

| 7204 | G | 20x47x15.5 | 1 | |||||||

| 7204 | G | 20x47x15.5 | 1 | Apron | ||||||

| 7204 | G | 20x47x15.5 | 1 | |||||||

| 7205 | G | 25x52x16.5 | 1 | Headstock | ||||||

| 7205 | G | 25x52x16.5 | 1 | Apron | ||||||

| 7205 | G | 25x52x16.5 | 1 | Feed box | ||||||

| 7206 | G | 30x62x17.6 | 1 | |||||||

| 7306 | G | 35x72x21 | 1 | Headstock | ||||||

| 7307 | G | 35x80x23 | 2 | |||||||

| 7506 | G | 30x62x21.5 | 1 | |||||||

| 7507 | G | 35x72x24.5 | 1 | |||||||

| Single thrust ball bearing | ||||||||||

| 8106 | D | 30x47x11 | 2 | Feed box | ||||||

| 8106 | G | 30x47x11 | 1 | Apron | ||||||

| 8205 | G | 25x47x15 | 1 | Tailstock | ||||||

| 8215 | D | 75x110x27 | 1 | Headstock | ||||||

| Single row centripetal ball bearing | ||||||||||

| 46215 | D | 75x130x25 | 1 | Headstock | ||||||

| Double row centripetal short cylindrical bearing | ||||||||||

| 3182121 | ID | 105x160x41 | 1 | Headstock | ||||||