Home » Products » ACCESSORIES » Machine Tool Spare Parts » CA Series Wearing Parts

CA Series Wearing Parts

INSPECTION AND MAINTENANCE OF THE MACHINE

Maintenance of the machine is necessary day-to-day work that keeps to the machine under. Good working status prolong serving life and increasing production efficiency of the machine.

Routine Inspection

After the 500-hour operation, it is necessary to carry out the regular check and maintenance for the machine. In most cases, give priority to operators to carry out the process, and the inspector and maintainer cooperate. While checking, it is necessary to switch of the power supply.

Periodic Inspection

After a certain time of working of the machine, owing to there is wear between the parts touching each other, working performance of them can be gradually affected, it is necessary to check them regularly to guarantee the accuracy of the machine, in general case, operator of the machine should take charge of this job by coaching of inspector and maintainer.

Home » Products » ACCESSORIES » Machine Tool Spare Parts » CA Series Wearing Parts

Contact

Wide Product Portfolio

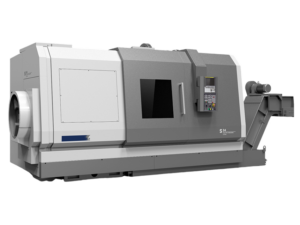

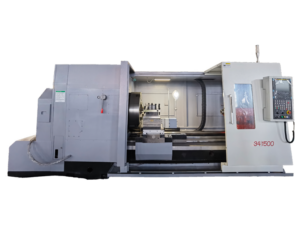

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

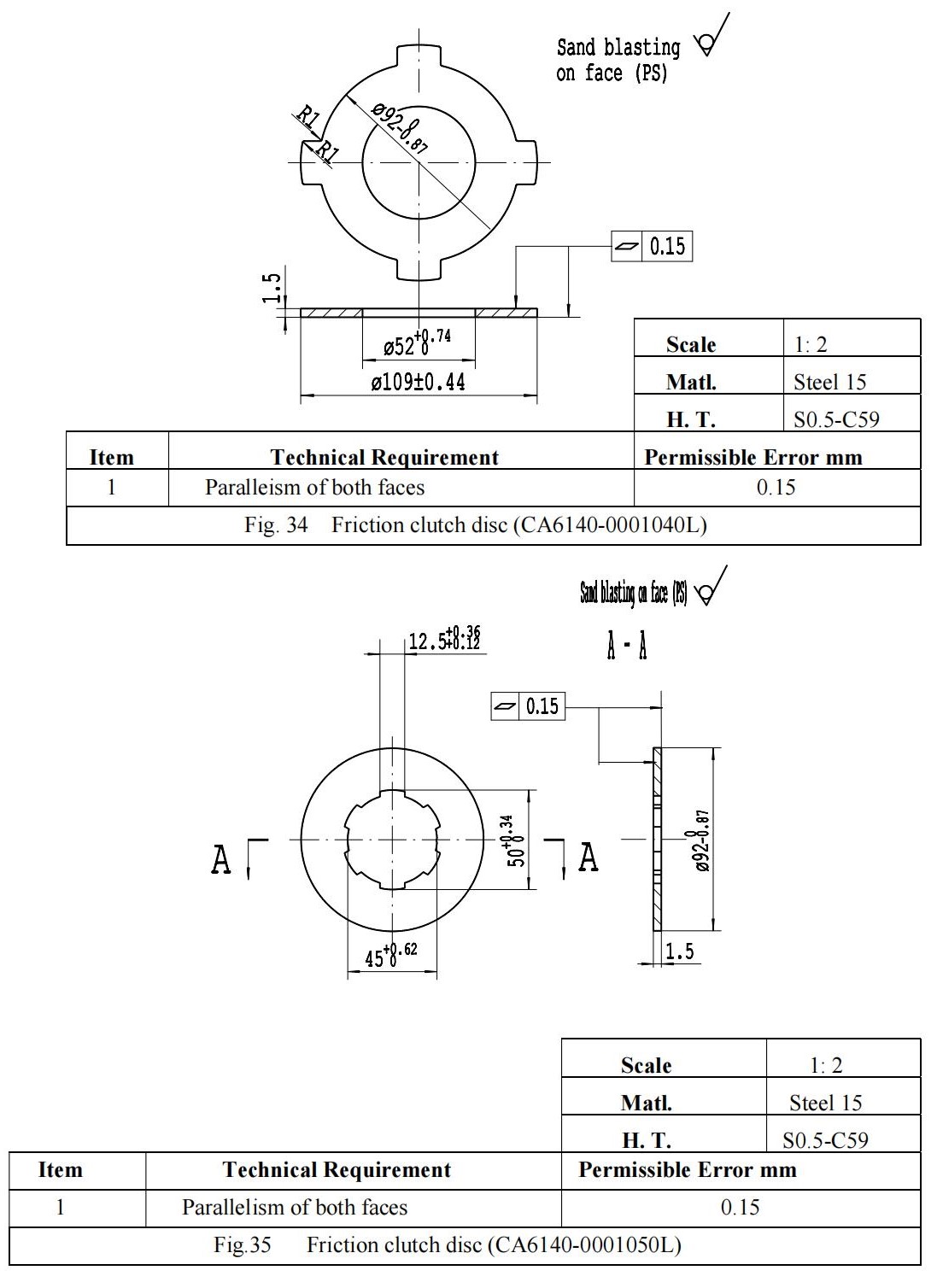

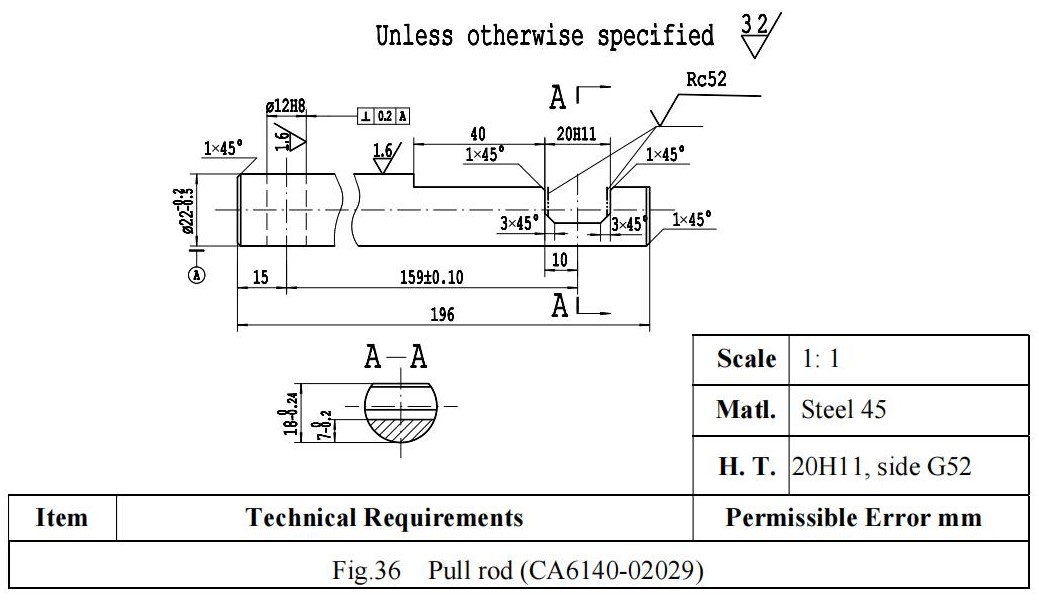

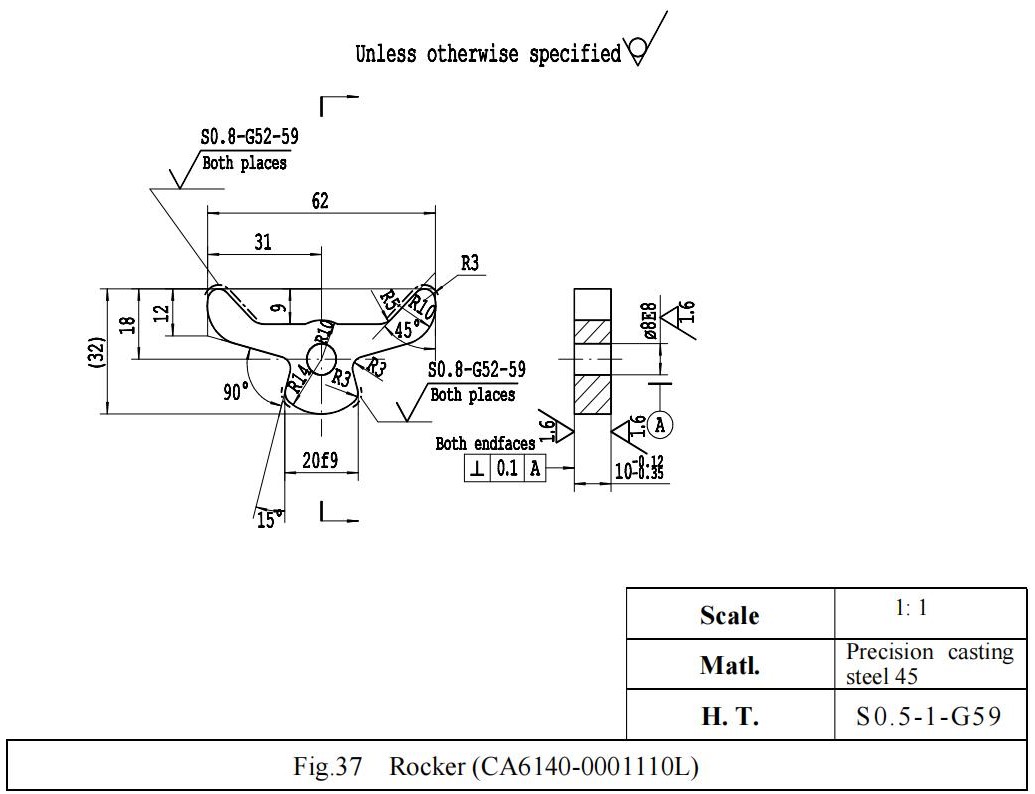

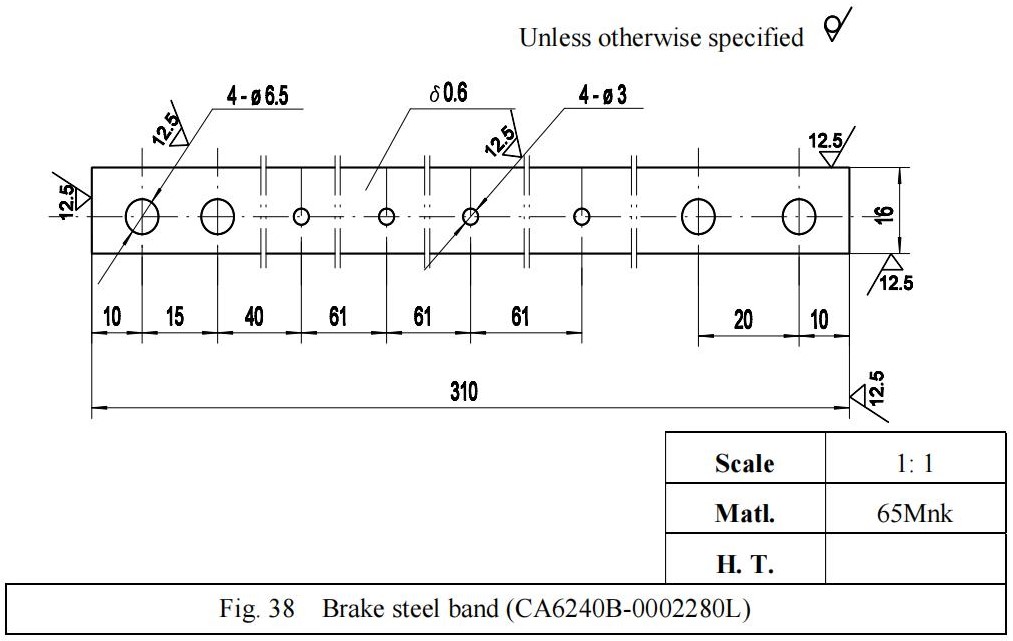

| Fig. No. | Part name | Part No. | Material | Qty. | Remarks | ||

|---|---|---|---|---|---|---|---|

| 34 | Friction clutch disc | CA6140-0001040L | Steel 15 | 12 | For the machine with hand-braking | ||

| 35 | Friction clutch disc | CA6140-0001050L | Steel 15 | 14 | |||

| 36 | Pull rod | CA6140-0001100L | Steel 45 | 1 | |||

| 37 | Lever | CA6140-0001110L | Precision casting | 1 | |||

| steel 45 | |||||||

| 38 | Brake steel band | CA6240B-0002280L | Steel 65 Mnk | 1 | For the machine with hand-braking | ||

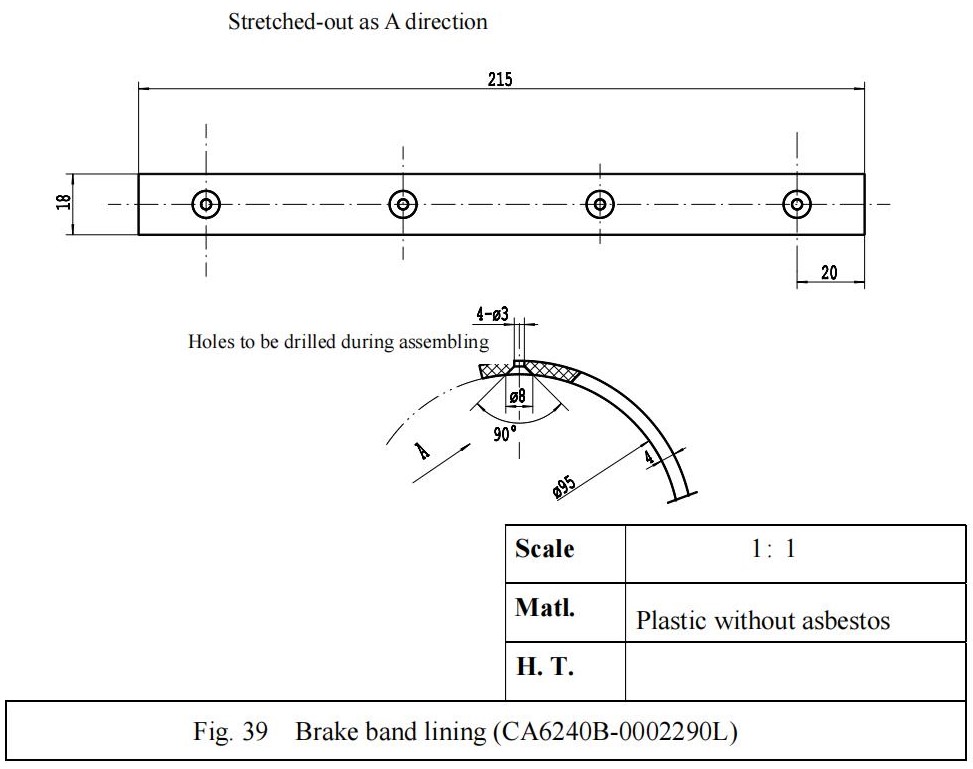

| 39 | Brake band lining | CA6240B-0002290L | Phenolic asbestos brake band | 1 | |||

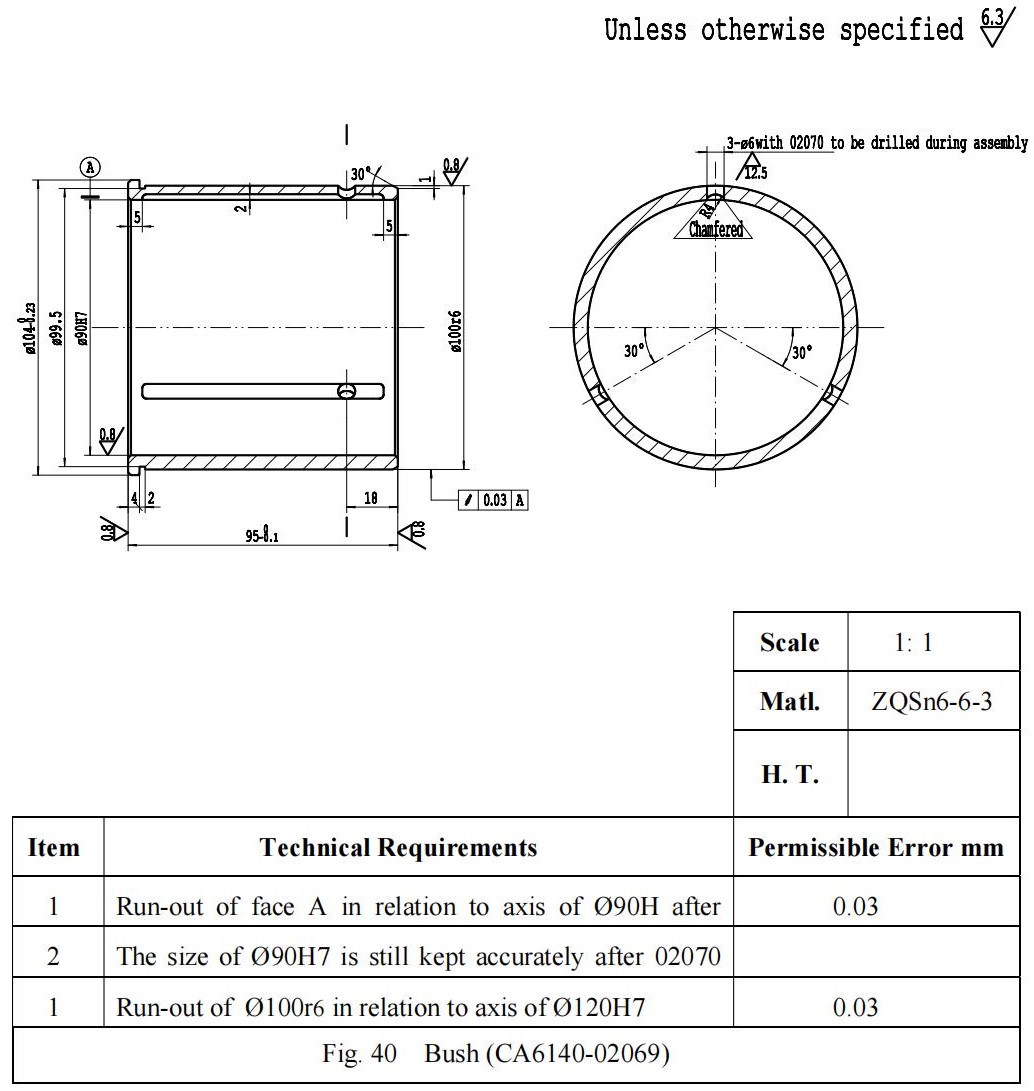

| 40 | Bushing | CA6140-02069 | ZQSn 6-6-3 | 1 | |||

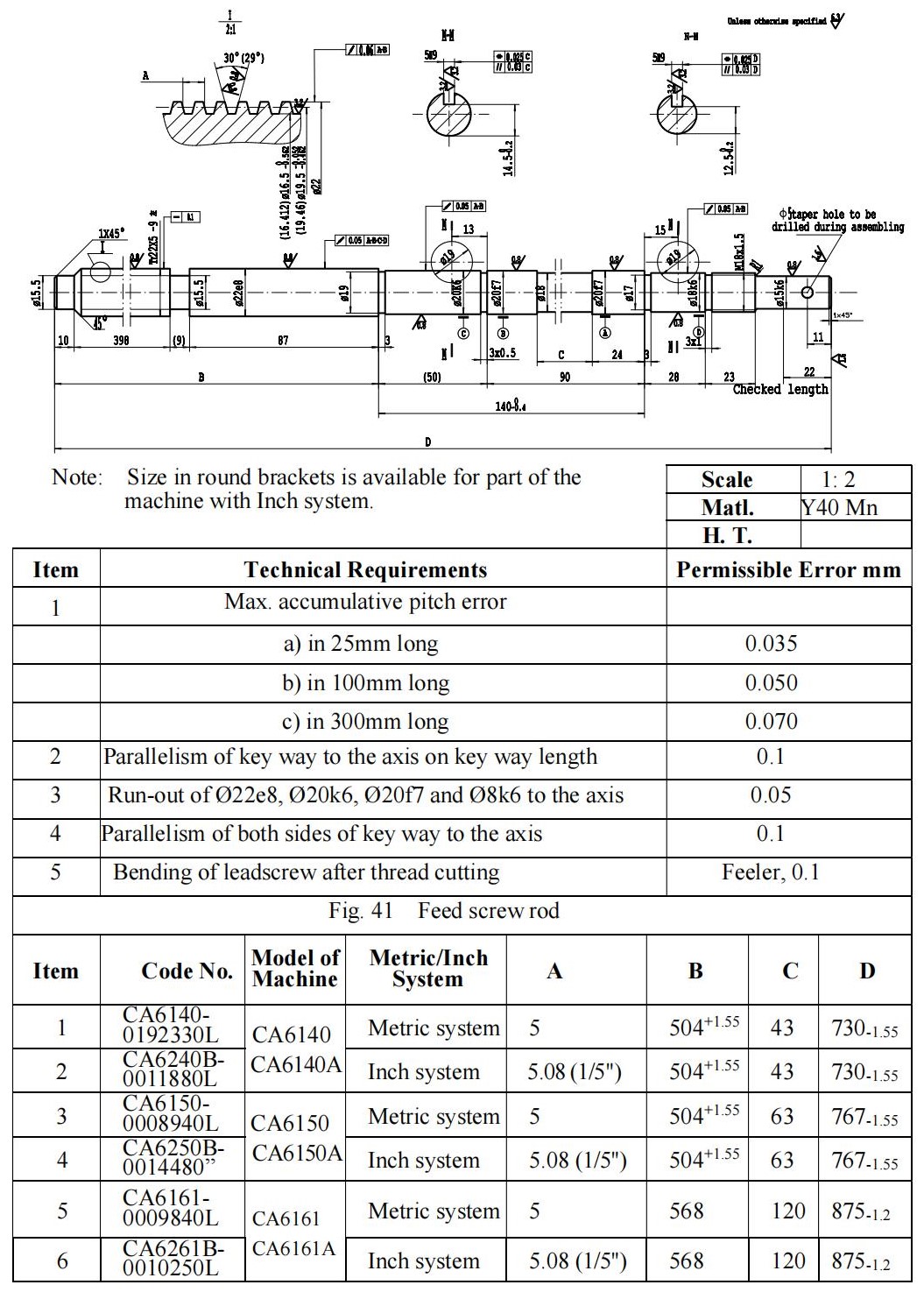

| 41 | Feed screw rod | CA6150 | 0008940L | Y40Mn | 1 | For CA6150, CA6150A machines with Metric system | |

| CA6250B | 0014480L | For CA6150, CA6150A machines with Inch system | |||||

| CA6161 | 0009840L | For CA6161, CA6161A machines with Metric system | |||||

| CA6261B | 0001025L | For CA6161, CA6161A machines with Inch system | |||||

| CA6140 | 0192330L | For CA6140, CA6144A machines with Metric system | |||||

| CA6240B | 0011880L | For CA6140, CA6140A machines with Inch system | |||||

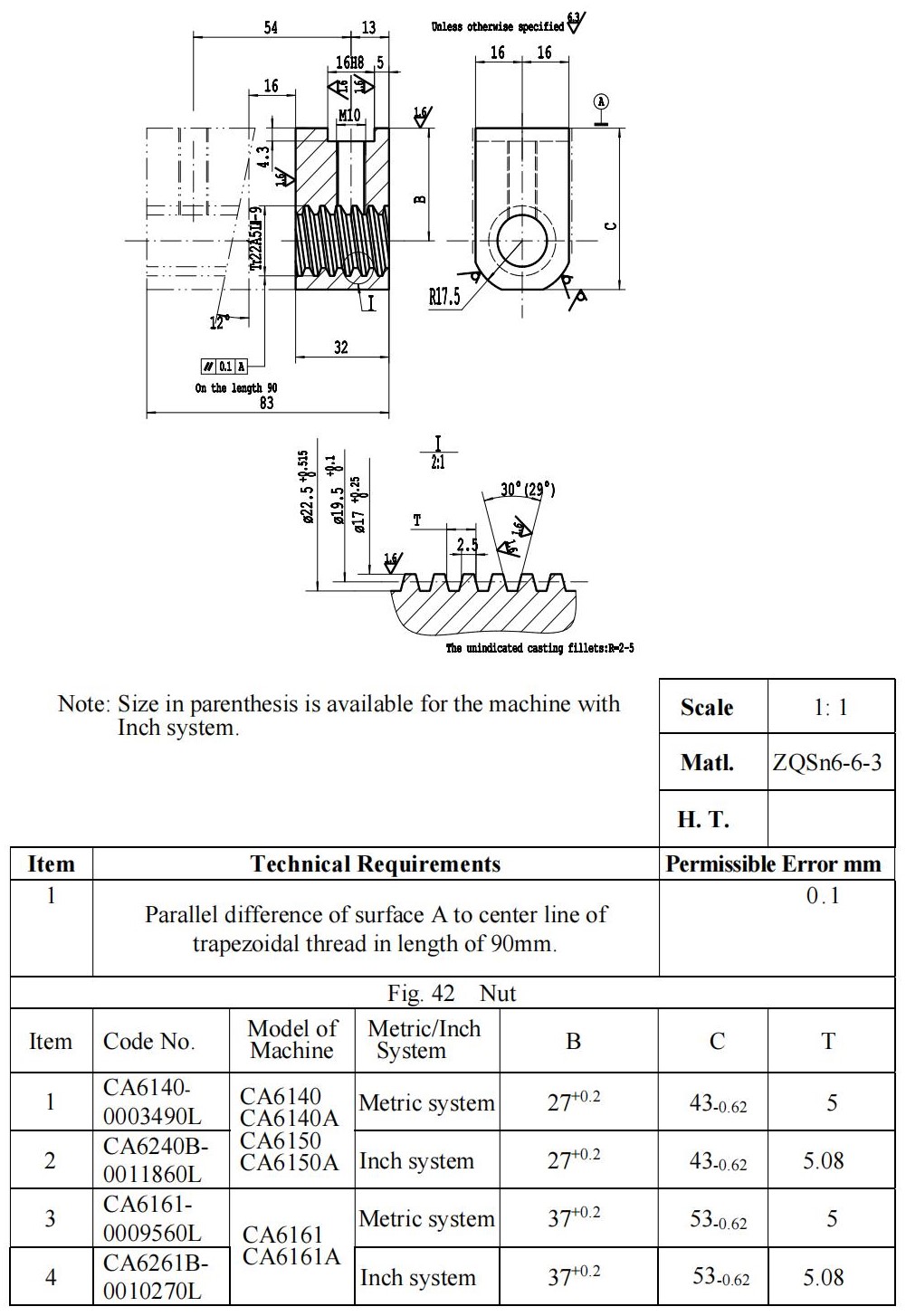

| 42 | Nut | CA6140 | 0003490L | ZQSn 6-6-3 | 1 | For CA6140, CA6140A, CA6150, CA6150A machines with Metric system | |

| CA6240B | 0011860L | For CA6140, CA6140A, CA6150, CA6150A machines with Inch system | |||||

| CA6161 | 0009560L | For CA6161,CA6161A, machines with Metric system | |||||

| CA6261B | 0010270L | For CA6161, CA6161A, machines with Inch system | |||||

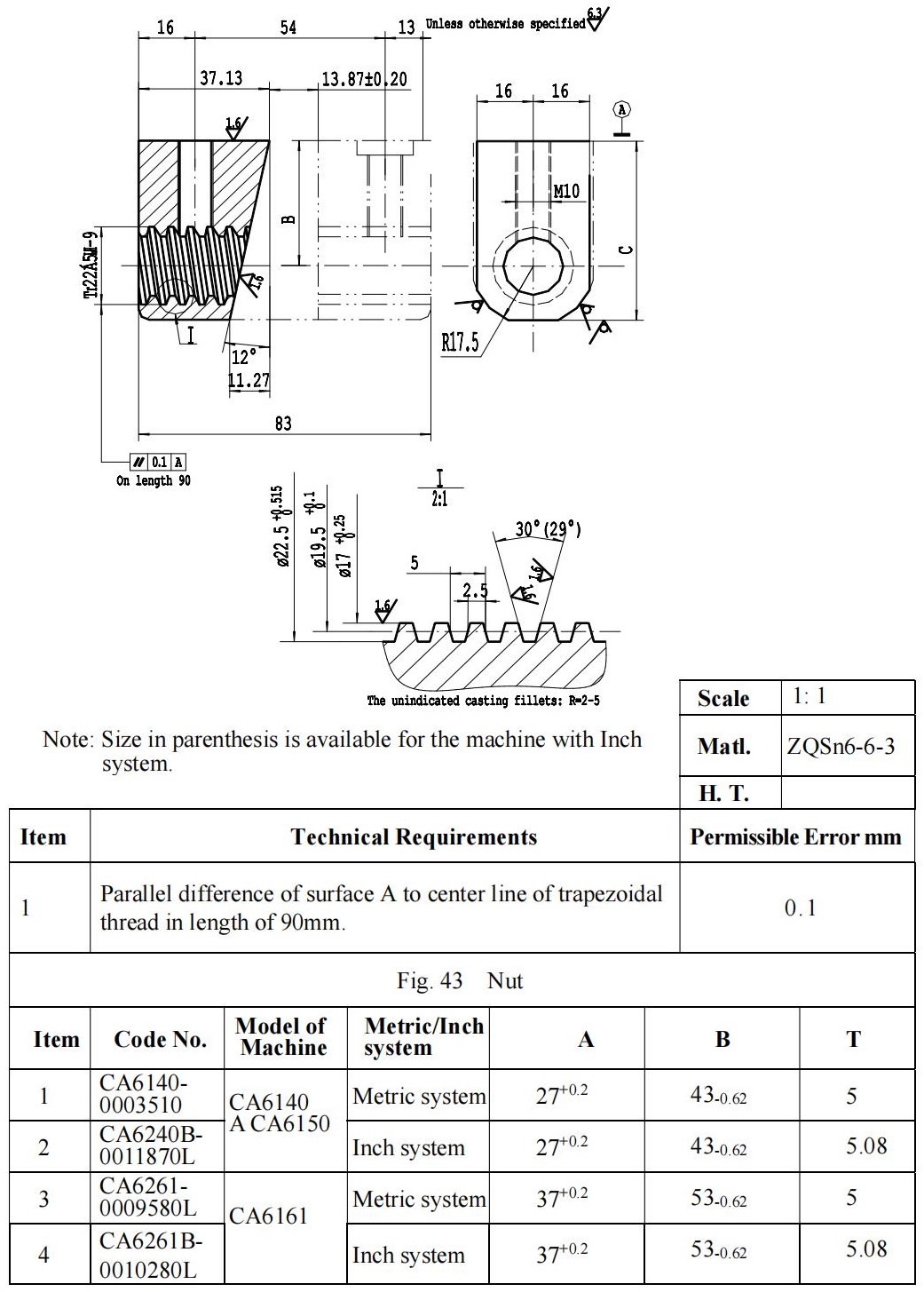

| 43 | Nut | CA6140 | 0003510L | ZQSn 6-6-3 | 1 | For CA6140, CA6140A, CA6150, CA6150A machines with Metric system | |

| CA6240B | 0011870L | For CA6140, CA6140A, CA6150, CA6150A machines with Inch system | |||||

| CA6161 | 0009580L | For CA6161, CA6161A, machines with Metric system | |||||

| CA6261B | 0010280L | For CA6161, CA6161A, machines with Inch system | |||||

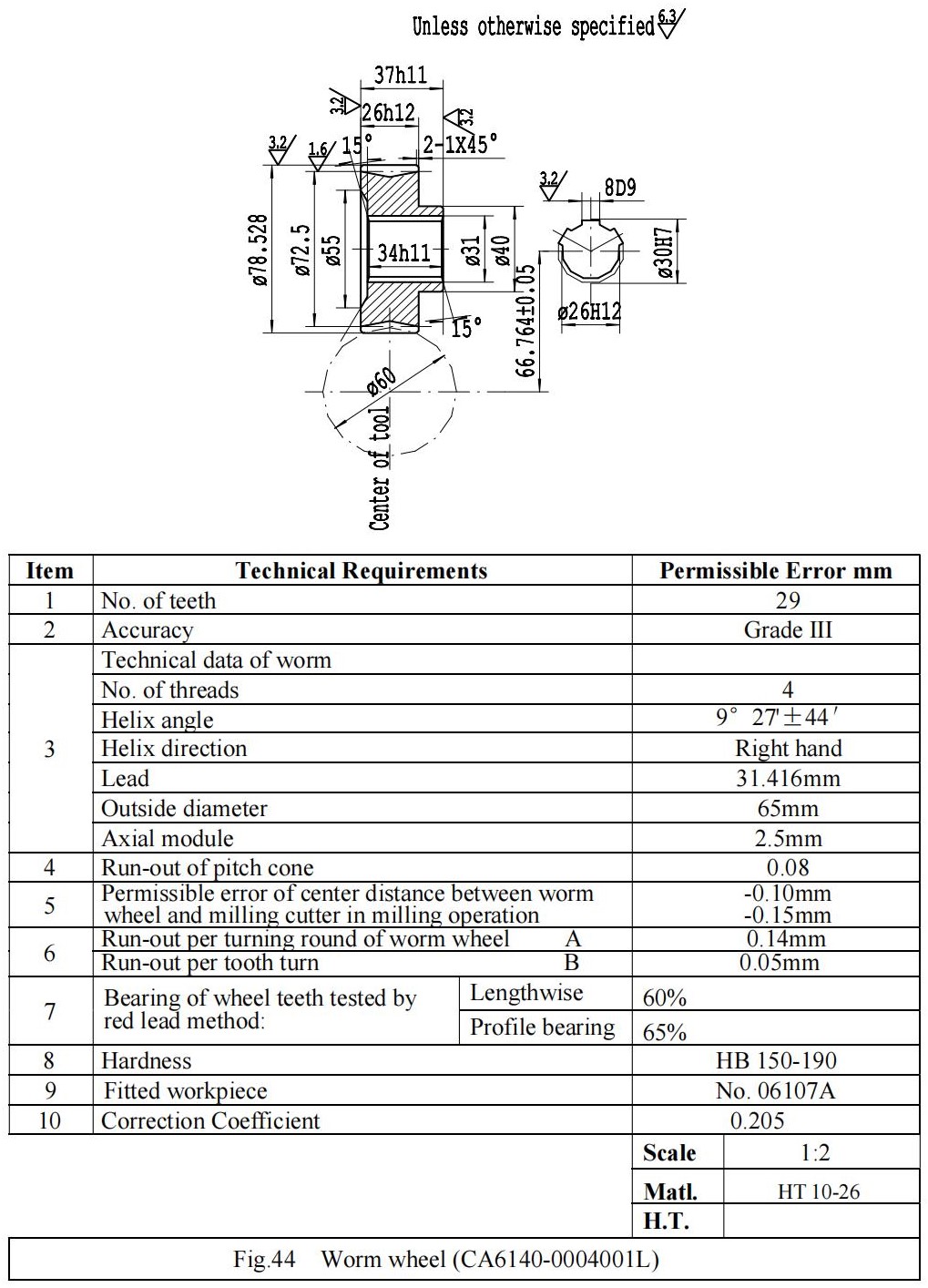

| 44 | Worm wheel | CA6140-0004001LA | HT10-26 | 1 | |||

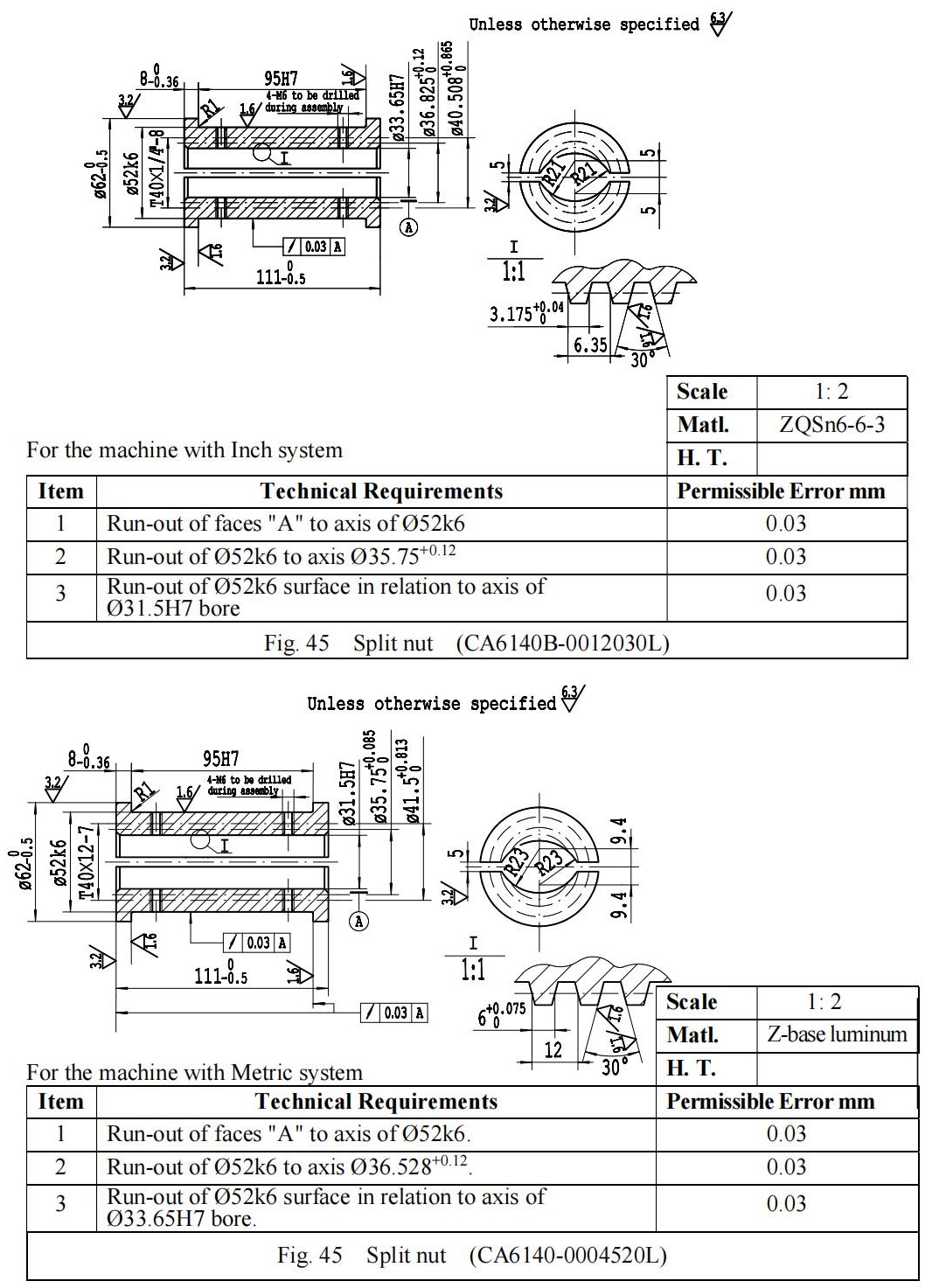

| 45 | Split nut | CA6140 | 0004520L | Allumen KYM | 1pair | For the machine with Metric system | |

| CA6240B | 0012030L | ZQSn 6-6-3 | For the machine with Inch system | ||||

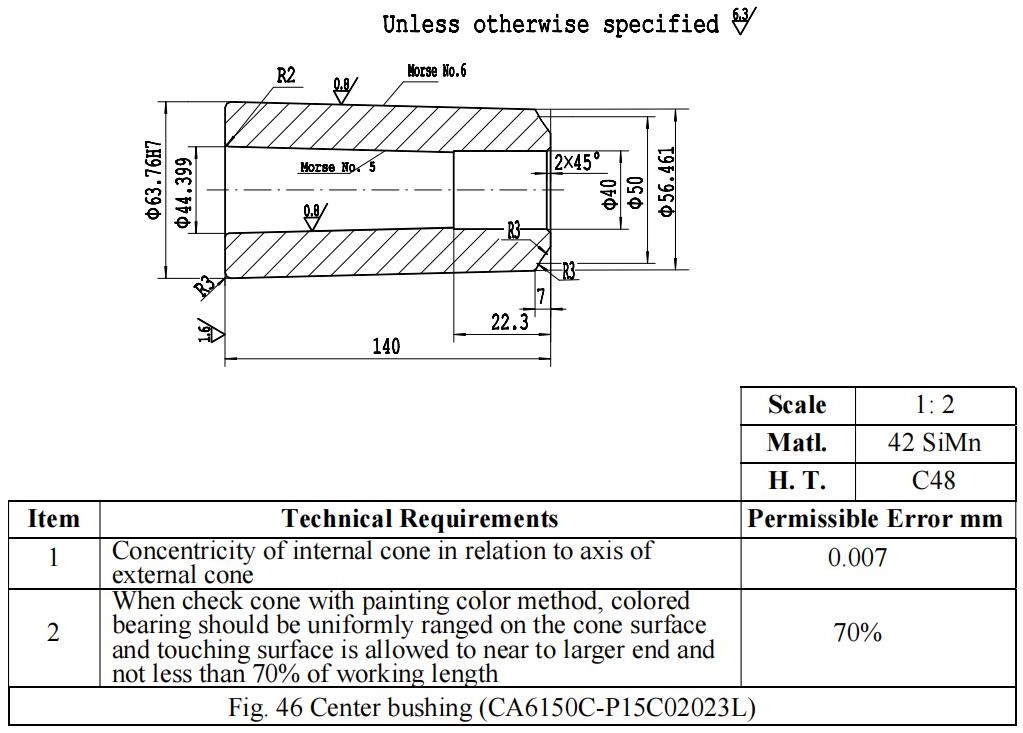

| 46 | Center bushing | 6/5S25 – 10 | 40Cr | 1 | |||

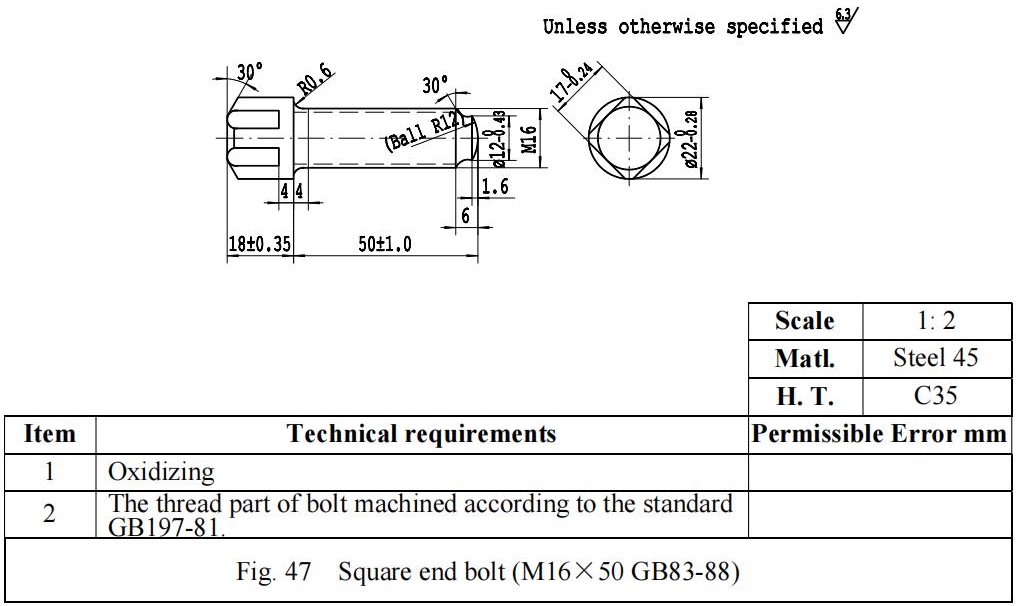

| 47 | Square end screw | M16´50, GB/T83-1988 | Steel 45 | 2 | |||

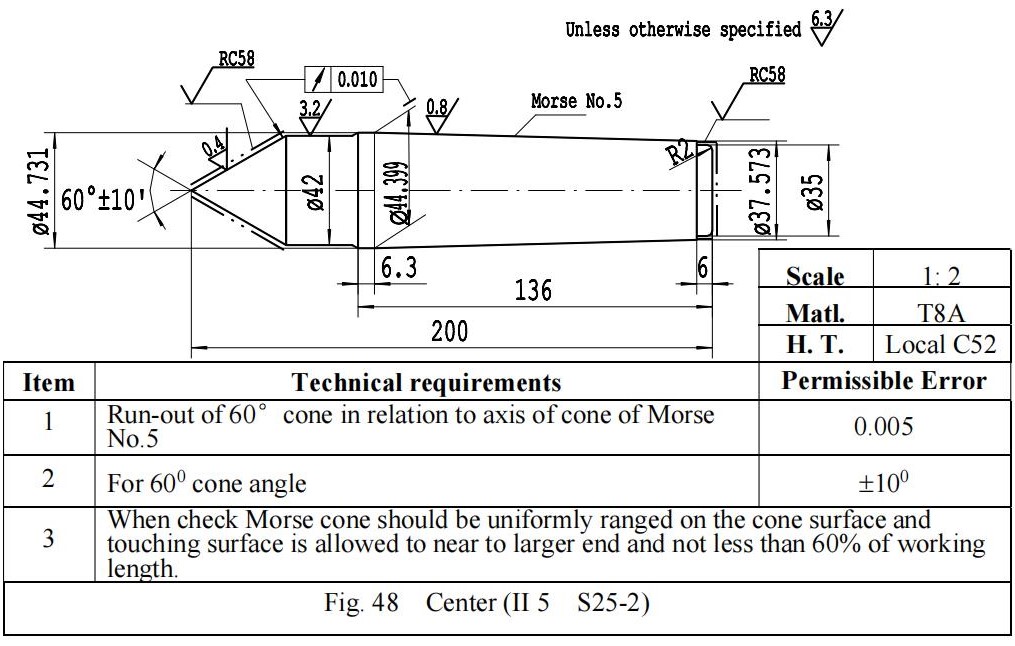

| 48 | Center | II. 5 S25-2 | T8A | 1 | |||

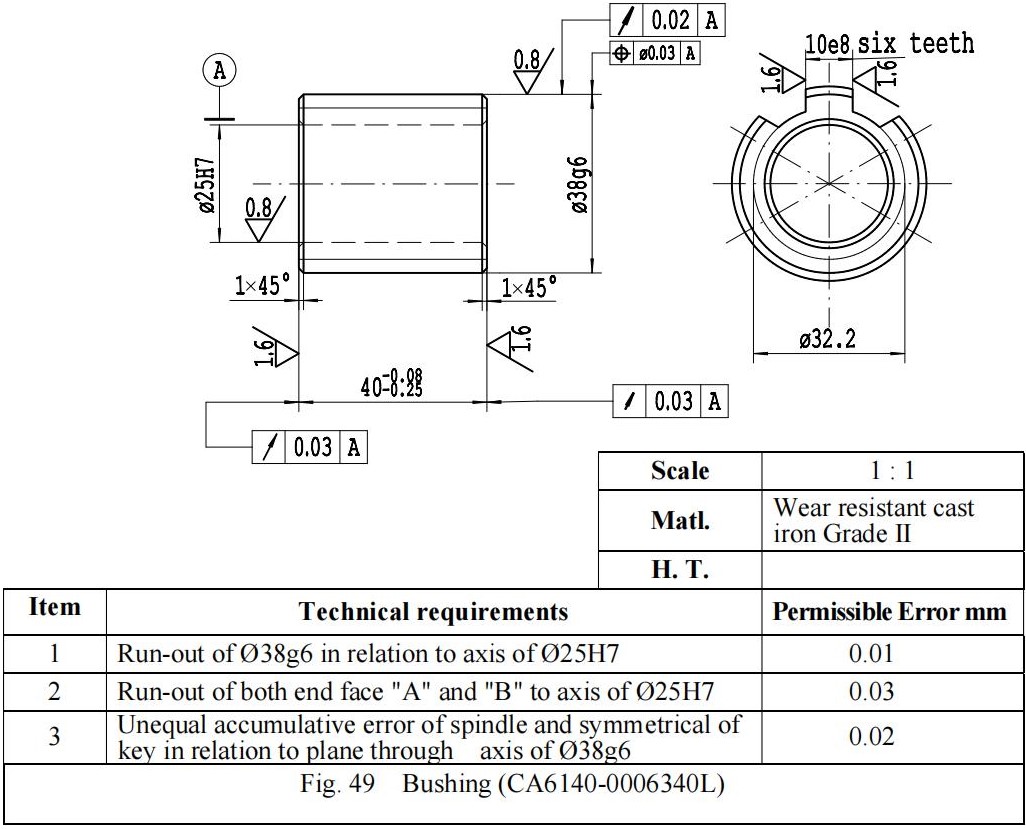

| 49 | Bushing | CA6140-0006340L | Wear resistant II | 1 | |||