Home » Products » ACCESSORIES » Machine Tool Spare Parts » STC1835,STC22100,STC34100 Wearing Parts

STC1835,STC22100,STC34100 Wearing Parts

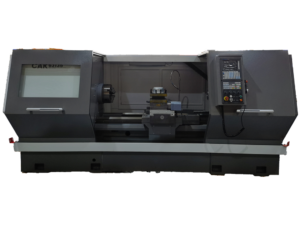

The STC series is a pipe threading lathe that combines economy, practicality, and professionalism, utilizing the FANUC system. Primarily designed for pipe threading machining, it can efficiently cut metric and British system cylindrical/conical threads. Additionally, this versatile machine tool is capable of handling various lathe operations, including work on shafts and disc components with diverse shapes and surfaces such as arc conical surfaces and ordinary thread internal and external cylindrical surfaces. Ideal for applications in the petroleum, metallurgical, chemical, and hydropower/geology sectors, it excels at machining drill pipes, drill collars, casing pipes, and petroleum casing pipes. Particularly well-suited for casing pipe machining in the petroleum industry, the machine tool achieves a normal machining accuracy of IT6-IT7, with a workpiece surface roughness reaching Ra1.3um. The STC series stands as a reliable and practical choice for large-scale machining of petroleum pipe threads.

Home » Products » ACCESSORIES » Machine Tool Spare Parts » STC1835,STC22100,STC34100 Wearing Parts

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| Technical Parameters | ||||||

|---|---|---|---|---|---|---|

| ITEM | Unit | STC34100 | STC34150 | STC34300 | ||

| Max. Swing Over Bed | mm | Ø900 | Ø900 | Ø900 | ||

| Max. Cutting Length | mm | 1000 | 1500 | 3000 | ||

| Max. Cutting Diameter | mm | Ø340 | Ø340 | Ø340 | ||

| Applicable Range for Oil Products | inch | 4 1/2″-13 3/8″ (Electrical Chuck) 5″-13 3/8″ (Hydraulic Chuck) | 4 1/2″-13 3/8″ (Electrical Chuck) 5″-13 3/8″ (Hydraulic Chuck) | 4 1/2″-13 3/8″ (Electrical Chuck) 5″-13 3/8″ (Hydraulic Chuck) | ||

| Spindle Speed Range | rpm | 7-301 (Electrical Chuck) 7-305 (Hydraulic Chuck) 90-350 (Main Servo) | 7-301 (Electrical Chuck) 7-305 (Hydraulic Chuck) 90-350 (Main Servo) | 7-301 (Electrical Chuck) 7-305 (Hydraulic Chuck) 90-350 (Main Servo) | ||

| Main Motor Output Power | Continuous/30 minutes | 18.5 22(Main Servo) | 22 22(Main Servo) | 22 30(Main Servo) | ||

| Spindle Through Hole Diameter | mm | Ø355 | Ø355 | Ø355 | ||

| X-axis Rapid Traverse Speed | m/min | 4 | 4 | 4 | ||

| Z-axis Rapid Traverse Speed | m/min | 8 | 8 | 8 | ||

| X-axis Travel | mm | 300 | 300 | 300 | ||

| Z-axis Travel | mm | 1000/900 | 1500/1400 | 3000/2900 | ||

| Machining Accuracy | – | IT7 | IT7 | IT7 | ||

| Surface Roughness of Machined Workpiece | – | Ra1.6 | Ra1.6 | Ra1.6 | ||

| Positioning Accuracy – X-axis | mm | 0.03 | 0.03 | 0.03 | ||

| Positioning Accuracy – Z-axis | mm | 0.04 | 0.04 | 0.04 | ||

| Repeat Positioning Accuracy – X-axis | mm | 0.01 | 0.01 | 0.01 | ||

| Repeat Positioning Accuracy – Z-axis | mm | 0.015 | 0.015 | 0.015 | ||

| Turret Type | – | Vertical 4 positions 40×40 | Vertical 4 positions 40×40 | Vertical 4 positions 40×40 | ||

| Machine Weight | kg | 8200 | 10000 | 12000 | ||

| Overall Dimension (LxWxH) | mm | 3792x1928x2060 | 4180x2170x2042 | 5710x2170x2042 | ||

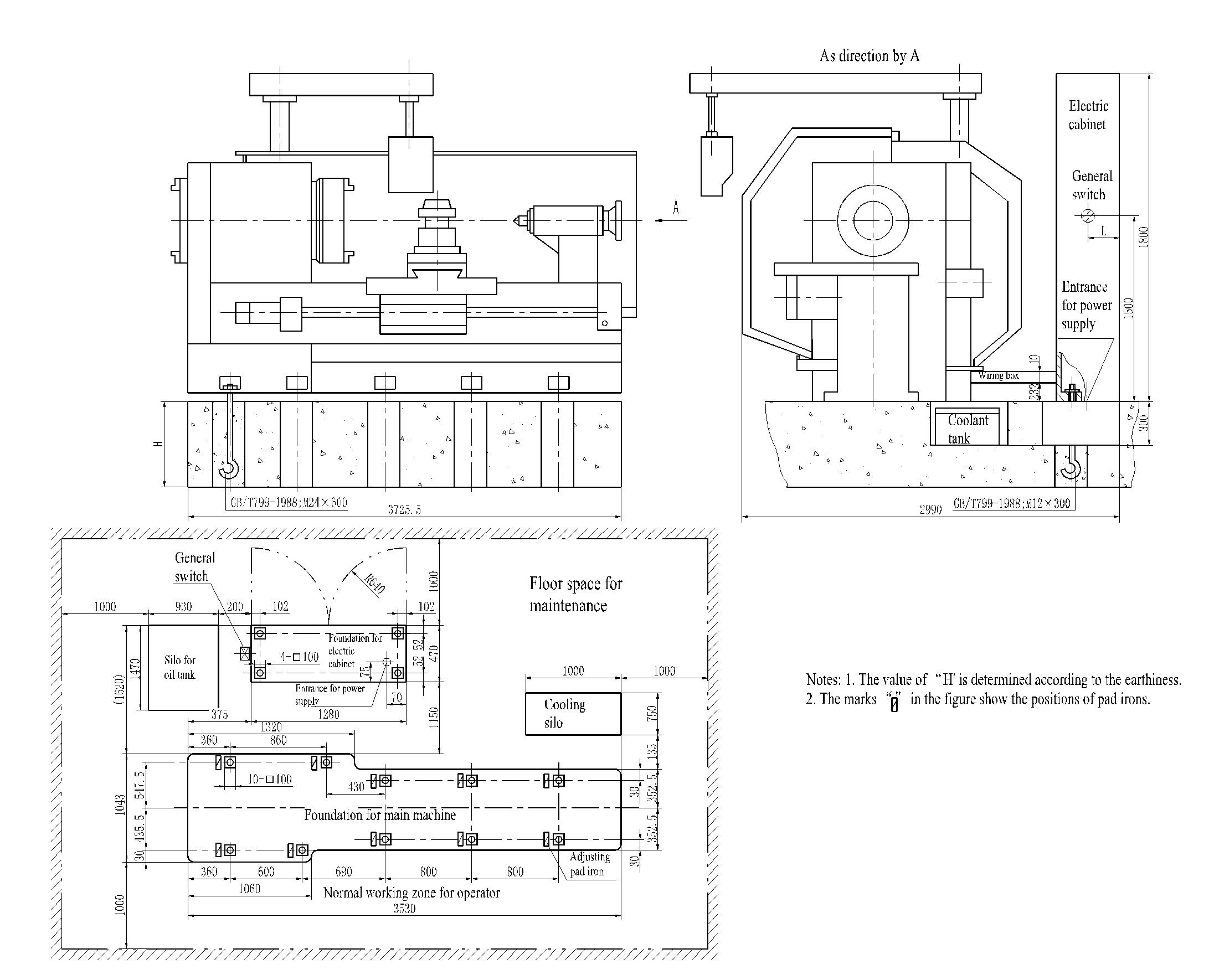

Foundation Plan of the Machine (1000mm)

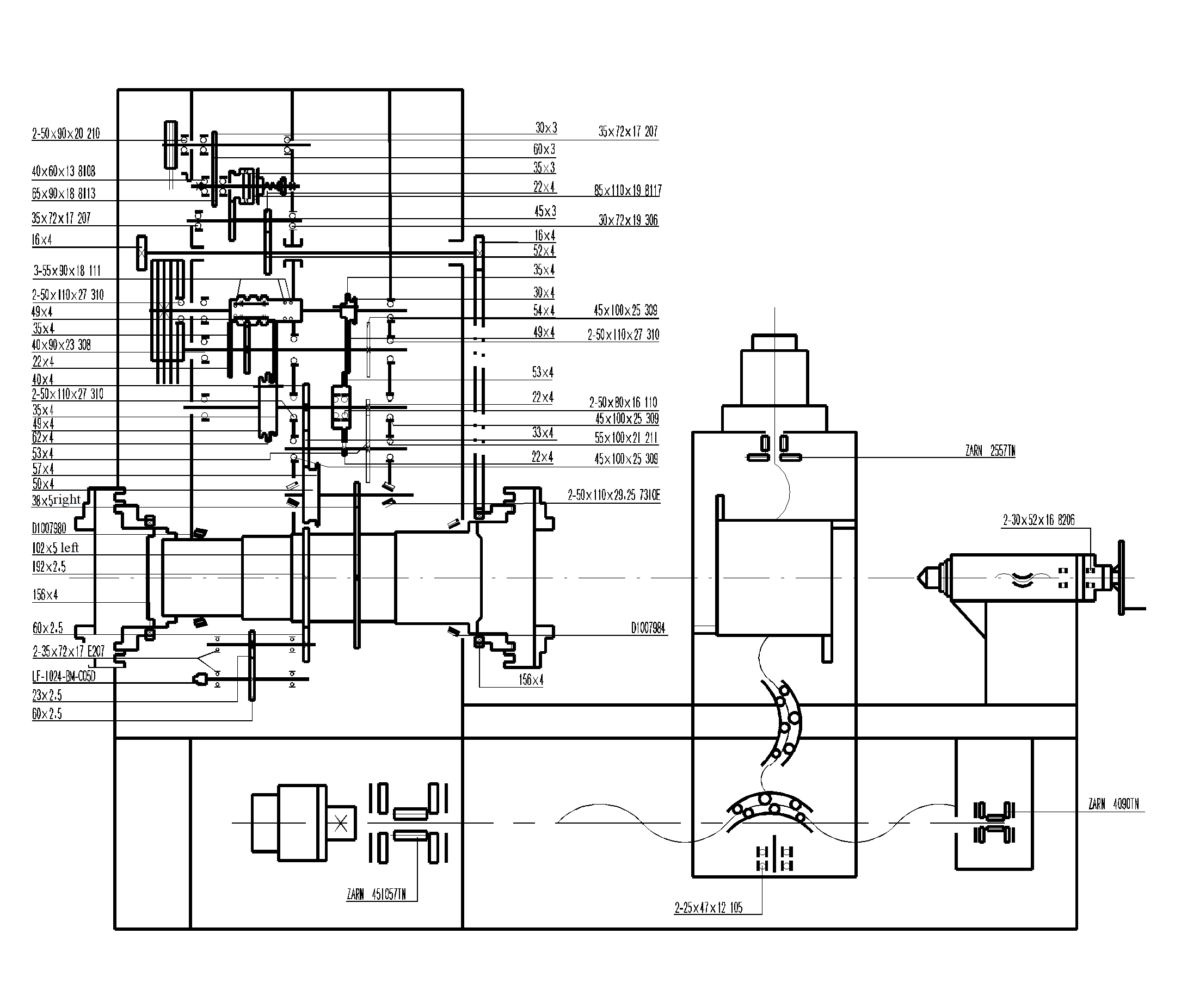

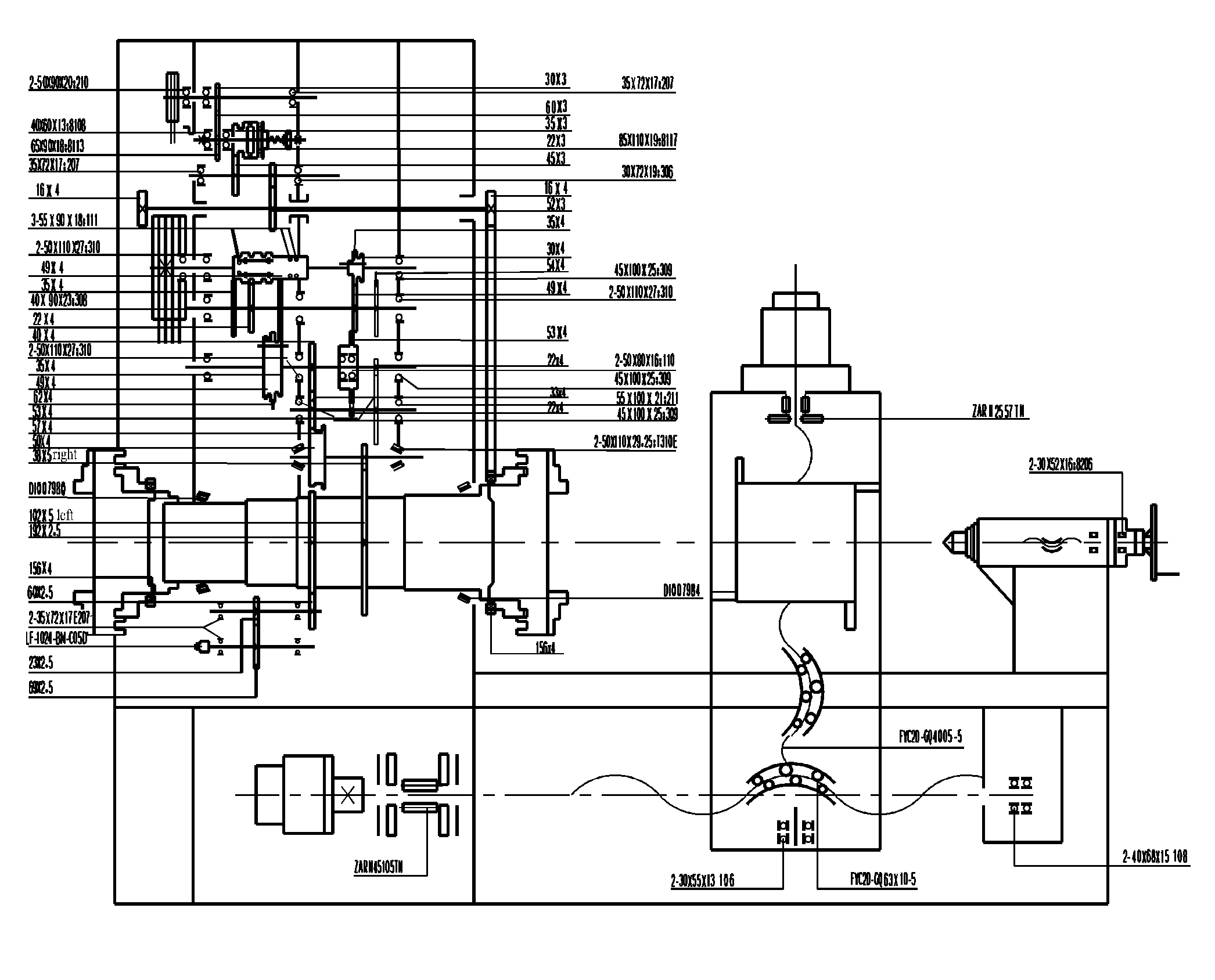

Drawing for Transmitting System and Bearing Arrangement

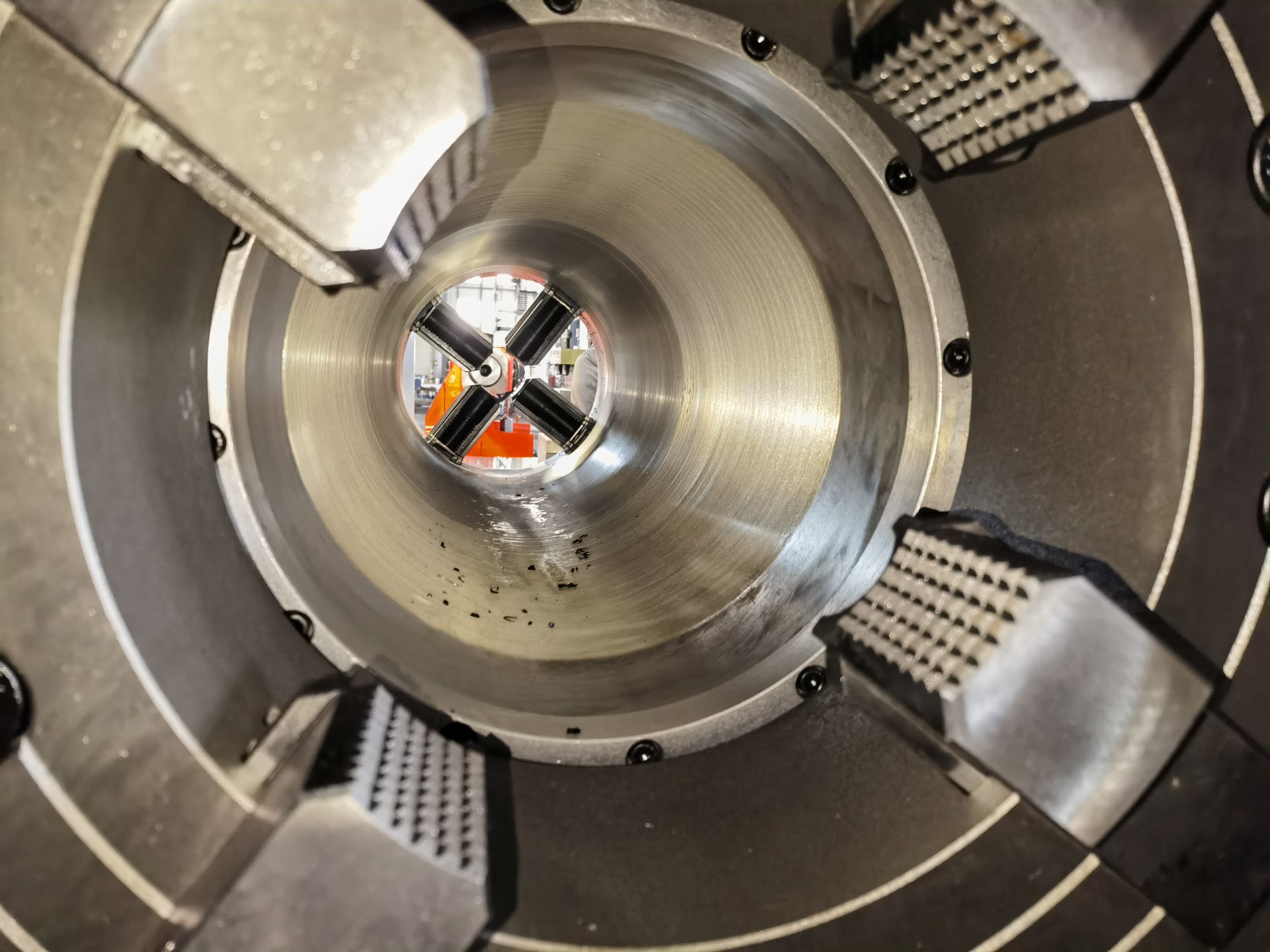

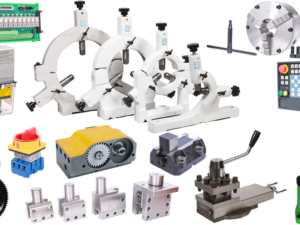

- Large Aperture Spindle

- Front and Rear Dual Chucks

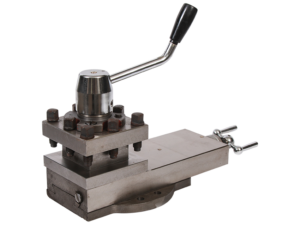

- Vertical 4 Positions Turret

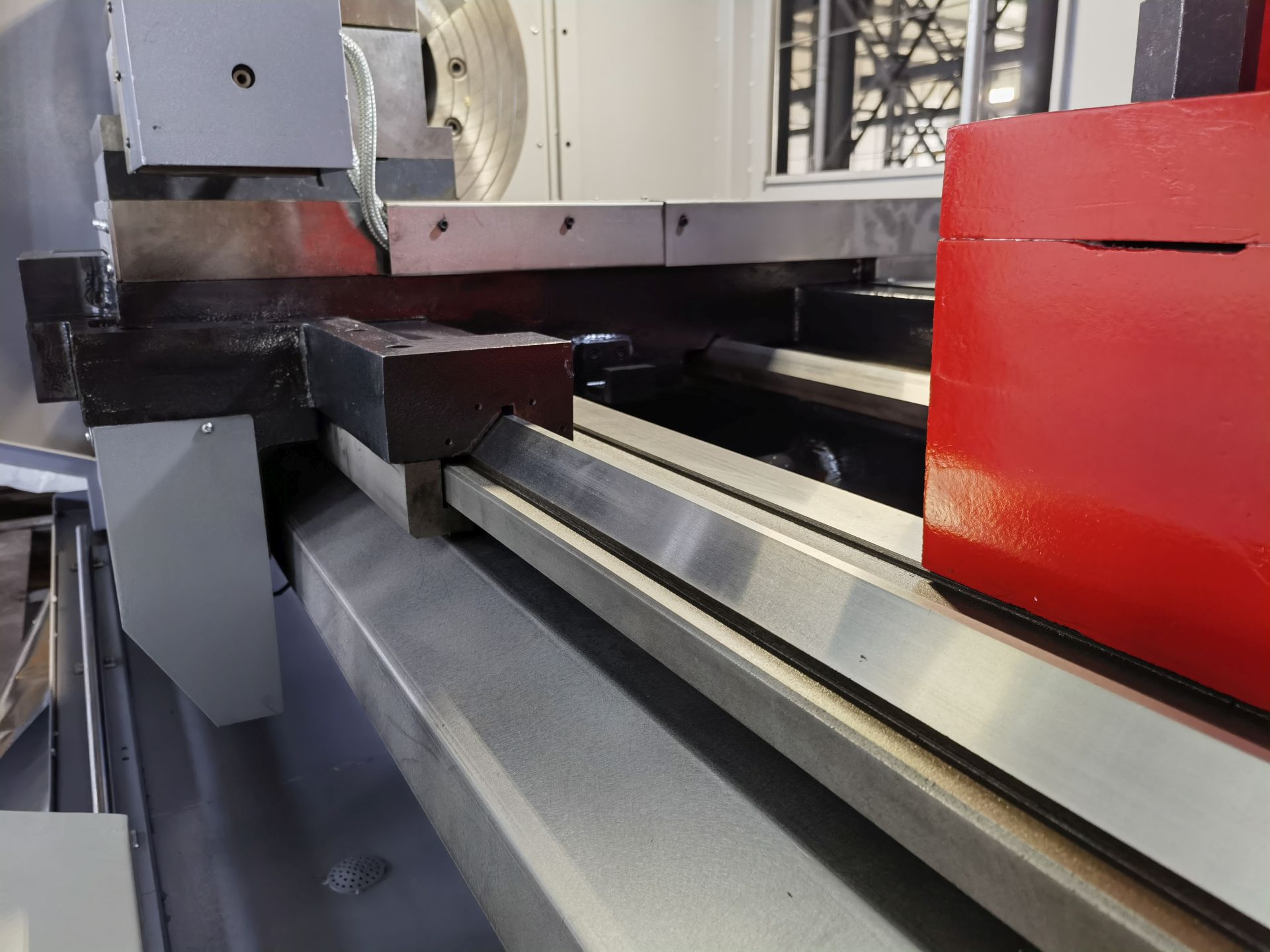

- Bed Guide Rail

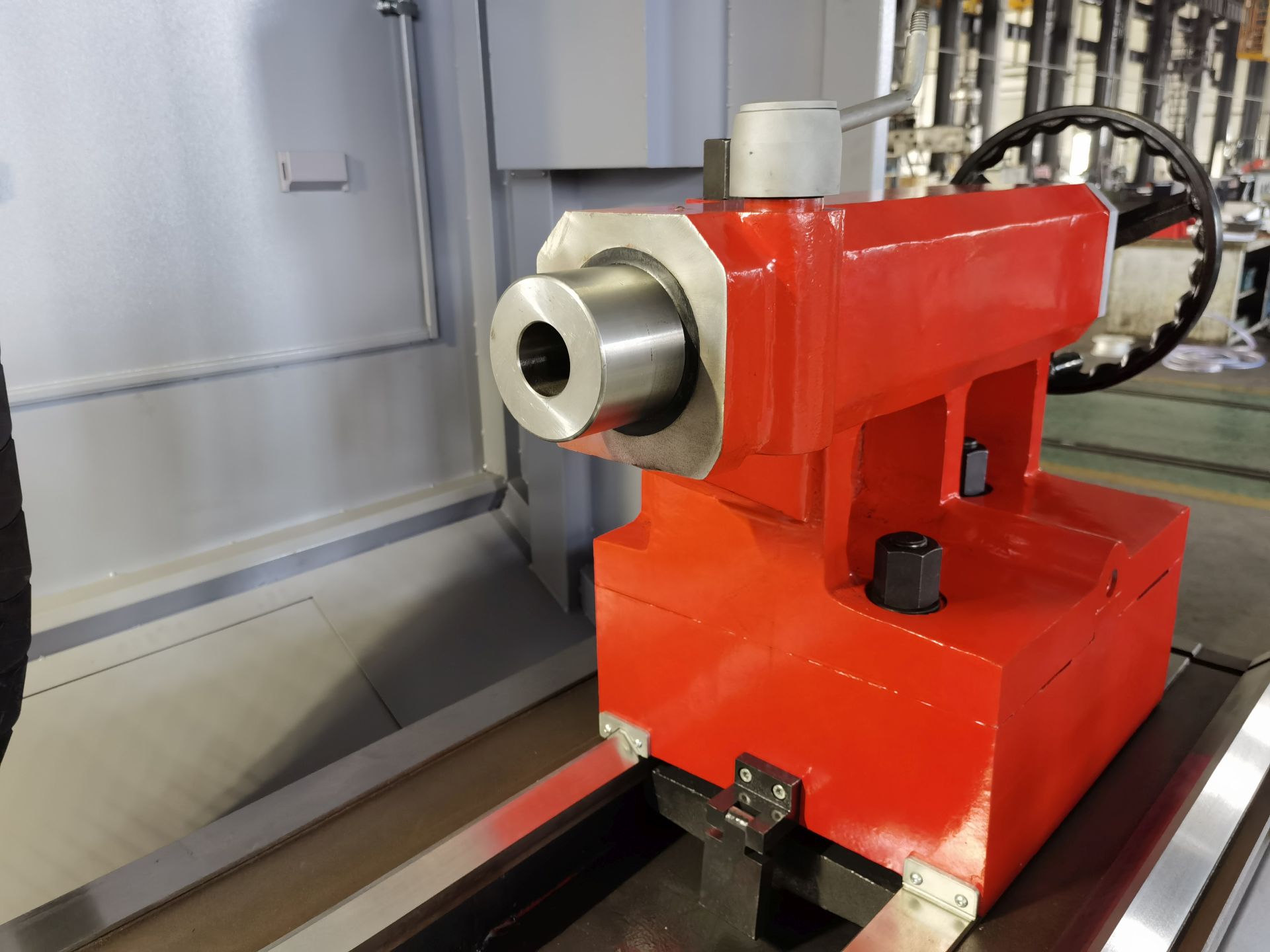

- Manual Tailstock

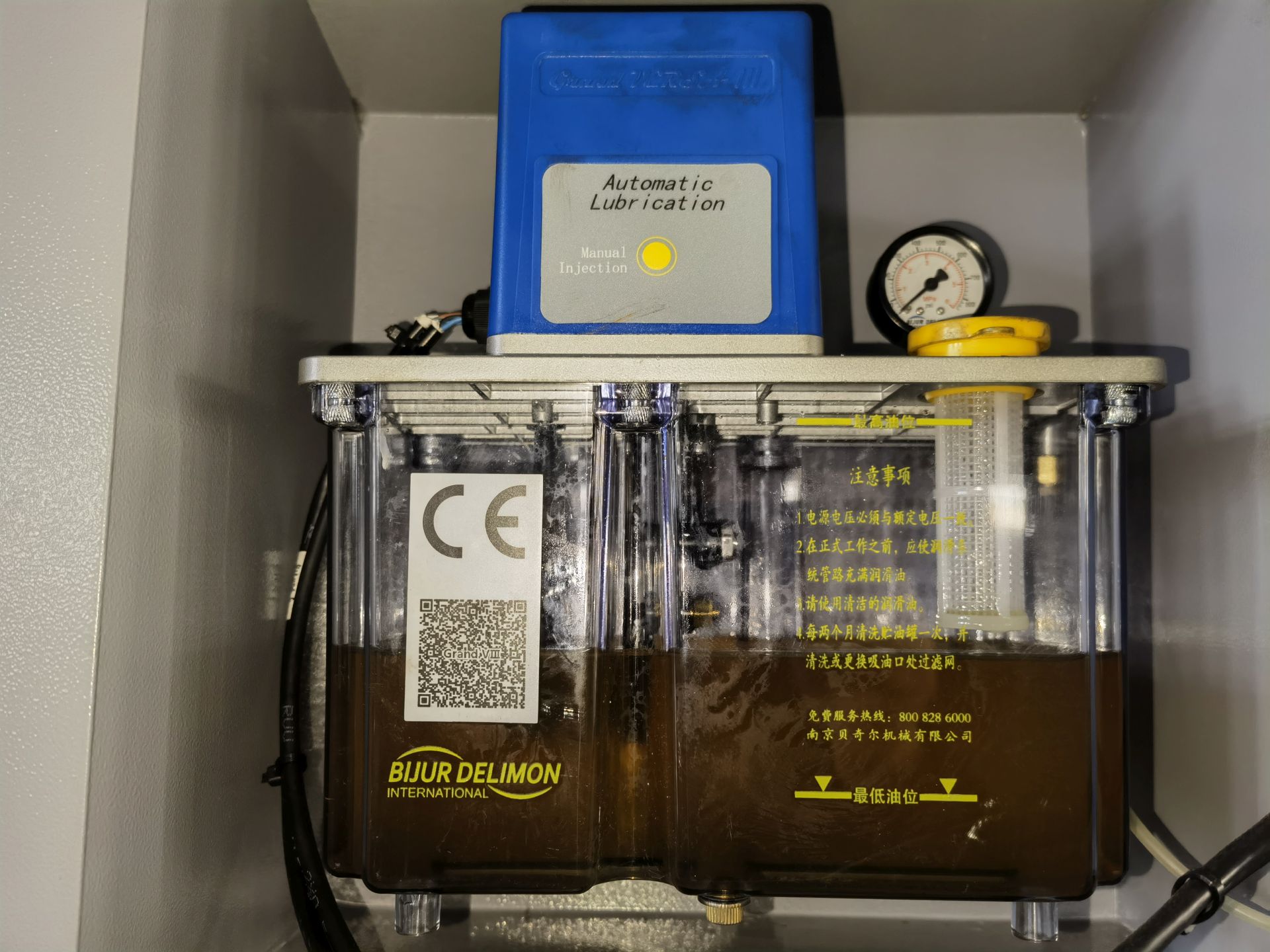

- Lubrication Station

- FANUC CNC Operating System

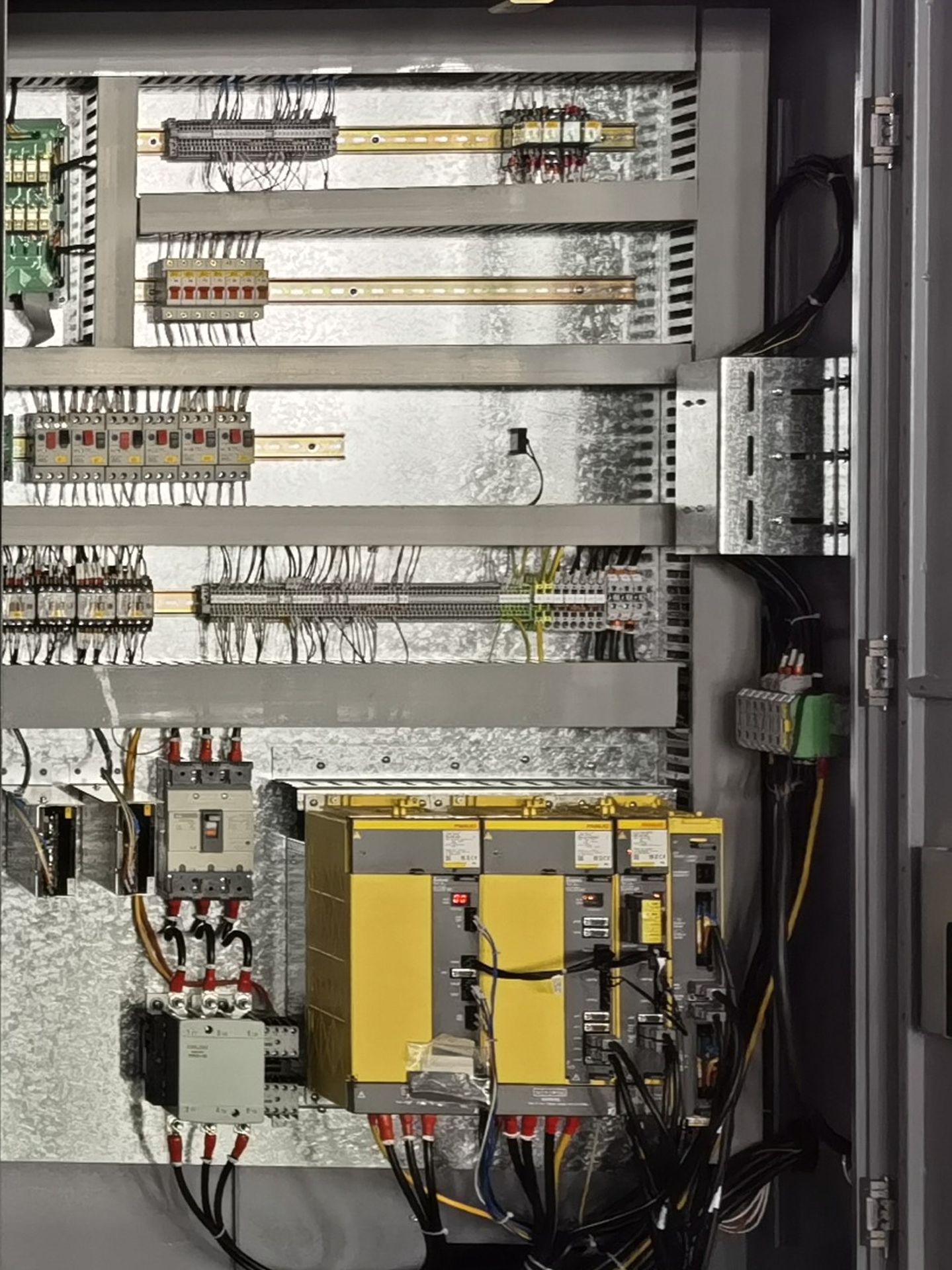

- Distribution Box

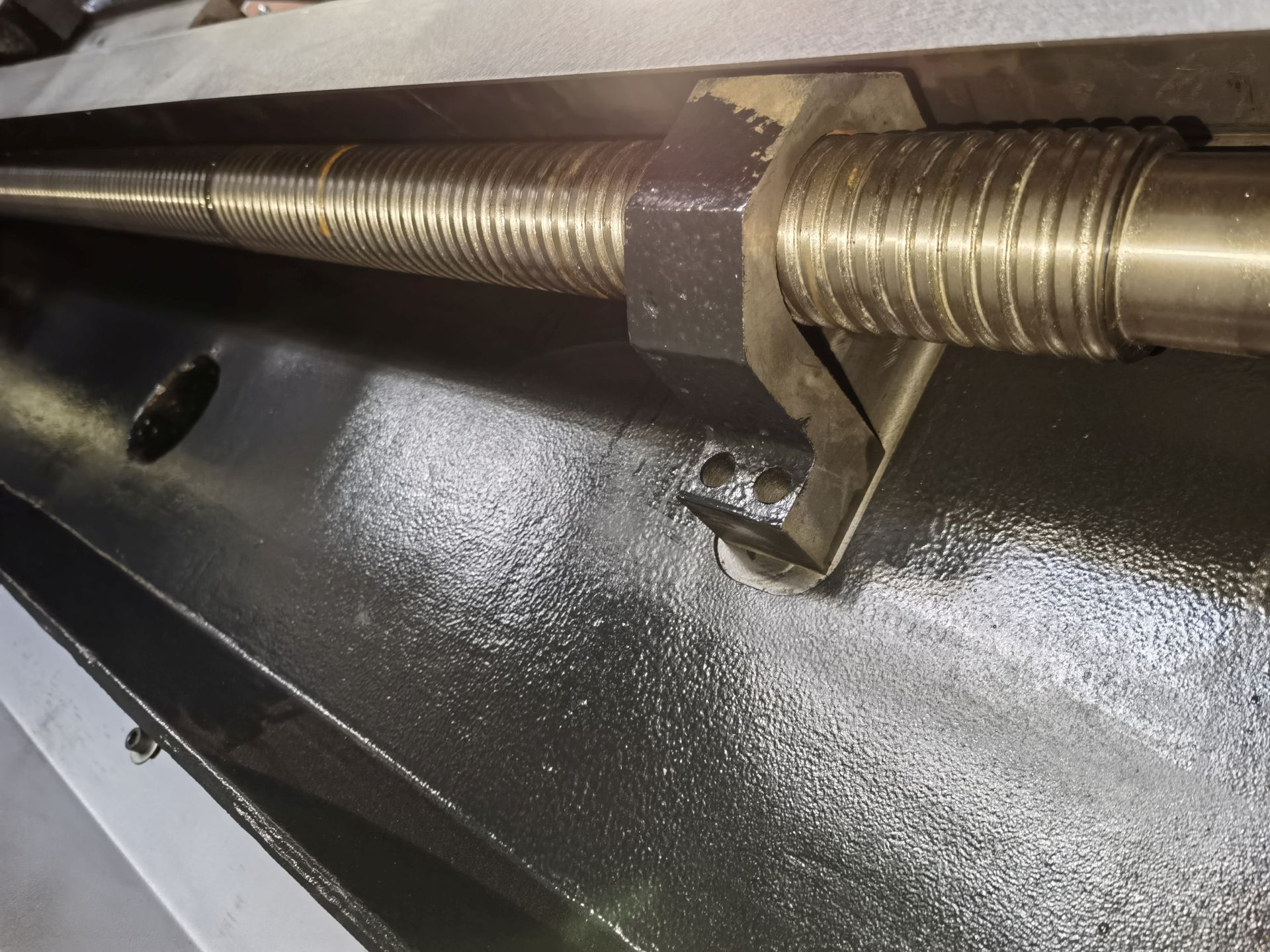

- Leadscrew

- Cabinet Air Conditioner

- FANUC αi Servo Amplifier

- FANUC Series 0i-MODEL F Plus