Home » Products » MACHINES » CNC Boring and Milling Machine » GMC-RV series GMC2060RV GMC2550RV GMC2560RV GMC2580RV GMC3060RV

GMC-RV series GMC2060RV GMC2550RV GMC2560RV GMC2580RV GMC3060RV

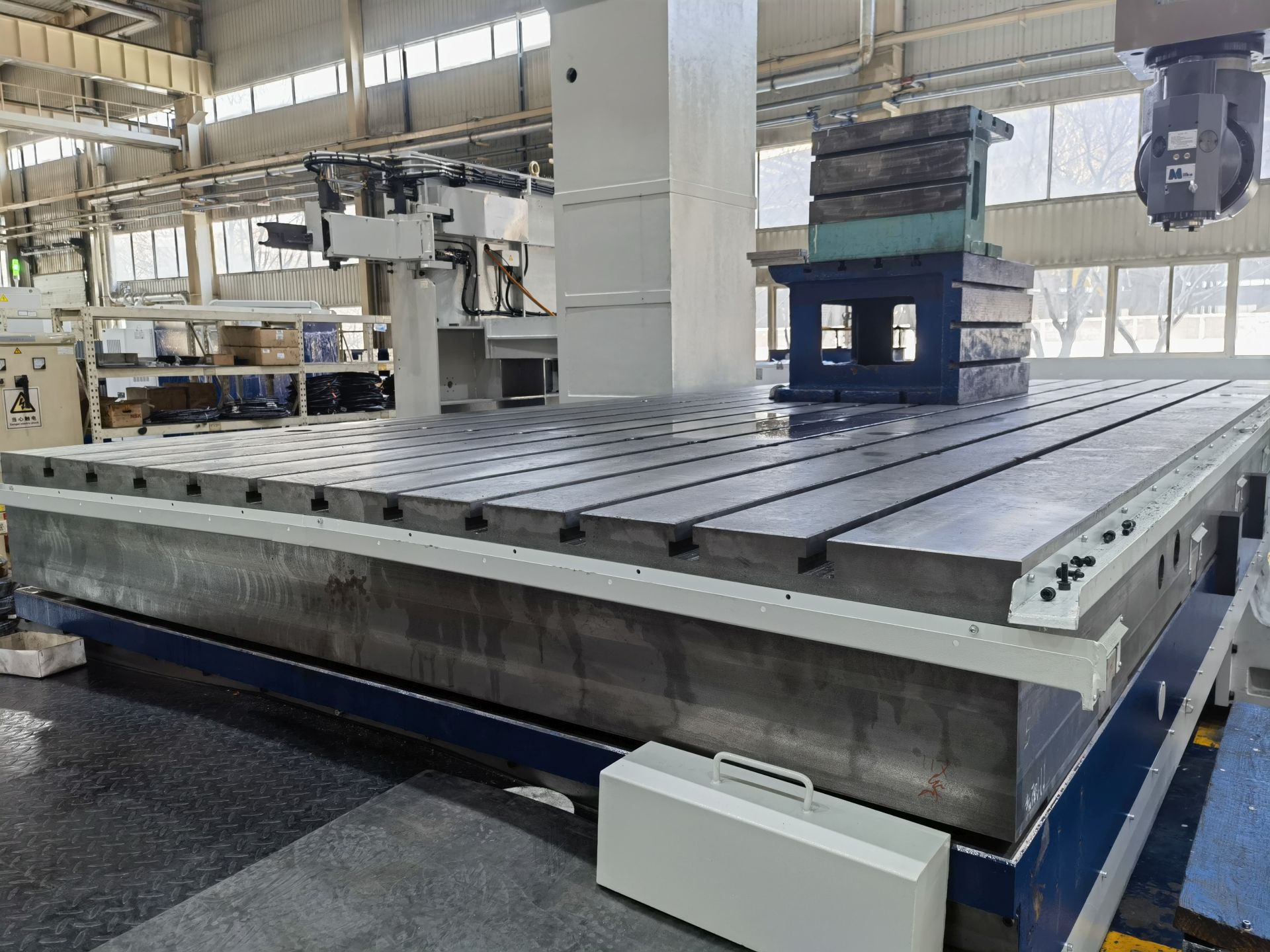

GMC-RV series machine tool is a gantry-type boring/milling machine featuring a moving workbench and a fixed crossbeam. It adopts a high rigidity wrap-around ram and is a high-speed and heavy-cutting machine tool.

The series of machine tools are used for machining various types of precise components, such as various fundamental large-size workpieces, plate workpieces, disc workpieces, housing workpieces, and molds. The product is configured with an automated right-angle milling head and is able to complete the machining of various procedures, including milling, boring, drilling,expanding, reaming, and rigid tapping of planes other than the installation bottom plane after one-time fixture.

Home » Products » MACHINES » CNC Boring and Milling Machine » GMC-RV series GMC2060RV GMC2550RV GMC2560RV GMC2580RV GMC3060RV

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| Item | unit | GMC 2060RV | GMC 2550RV | GMC 2560RV | GMC 2580RV | GMC 3060RV | ||

|---|---|---|---|---|---|---|---|---|

| Workbench | Dimension of workbench | mm | 2000×6000 | 2500×5000 | 2500×6000 | 2500×8000 | 3000×6000 | |

| Distance between two columns | mm | 2800 | 3300 | 3300 | 3300 | 3800 | ||

| Load capacity of workbench | kg | 23000 | 22000 | 25000 | 25000 | 30000 | ||

| T-shaped groove width | mm×pcs | 22×11 | 28×11 | 28×11 | 28×11 | 28×15 | ||

| Machining range | Workbench travel-X axis | mm | 6200 | 5200 | 6200 | 8200 | 6200 | |

| Slide travel-Y axis | mm | 3000 | 3500 | 3500 | 3500 | 4000 | ||

| Ram travel-Z axis | mm | 1000[1250] | 1000 | 1000[1250] | 1000[1250] | 1000[1250] | ||

| Distance from spindle nose to workbench Maximum | mm | 1400 | 1350 | 1350 | 1350 | 1350 | ||

| Distance from spindle nose to workbench Minimum | mm | 400[150] | 350 | 350[100] | 350[100] | 100 | ||

| Spindle | Taper hole(7:24) | BT50 | BT50 | BT50 | BT50 | BT50 | ||

| Speed range | r/min | 40-6000 | 40-4500 | 40-6000 | 40-6000 | 40-4500 | ||

| Output torque (rated/30min) | N.m | 770/924 | 770/924 | 770/924 | 770/924 | 1050/1260 | ||

| Spindle motor power(frated/30min) | kW | 22/26.4 | 22/26.4 | 22/26.4 | 22/26.4 | 30/36 | ||

| Section size of rectangle ram | mm | 400×400 | 400×400 | 400×400 | 400×400 | 400×400 | ||

| Feeding | Feed speed range | mm/min | 1-8000 | 1-6000 | 1-6000 | 1-6000 | 1-6000 | |

| Rapid motion X-axis | m/min | 12 | 12 | 12 | 10 | 10 | ||

| Rapid motion Y-axis | m/min | 15 | 12 | 12 | 12 | 12 | ||

| Rapid motion Z-axis | m/min | 12 | 12 | 12 | 12 | 12 | ||

| Positioning accuracy of the machine | X-axis | mm | 0.04 | 0.035 | 0.04 | 0.045 | 0.04 | |

| Y-axis | mm | 0.025 | 0.03 | 0.03 | 0.03 | 0.036 | ||

| Z axis | mm | 0.02[0.022] | 0.02 | 0.02[0.022] | 0.02[0.022] | 0.02[0.022] | ||

| Repeatability accuracy | X-axis | mm | 0.02 | 0.018 | 0.02 | 0.025 | 0.02 | |

| Y-axis | 0.012 | 0.014 | 0.014 | 0.014 | 0.018 | |||

| Z-axis | mm | 0.008[0.010] | 0.008 | 0.008[0.010] | 0.008[0.010] | 0.01 | ||

| Total electric capacity | KVA | 80 | 80 | 80 | 80 | 90 | ||

| Floor spacerequired bythe machine (L*W*H) | mm | 18000×8300×6200[6500] | 15000x8500x6400 | 18000×9000×6400[6700] | 23000×9000×6400[6700] | 18000×9800 ×6700 | ||

- Fixed crossbeam

- High rigidity wrap-around ram

- Customizable CNC operating system

- Moving workbench

- Worktable

- Bed guide rail

- Hydraulic station

- Lubrication station

- Optional: fully automated right-angle milling head

-

Optional: chain-plate type tool magazine,

vertical or vertical/horizontal tool change