Home » Products » MACHINES » CNC Boring and Milling Machine » PBC Series PBC110m PBC130m

PBC Series PBC110m PBC130m

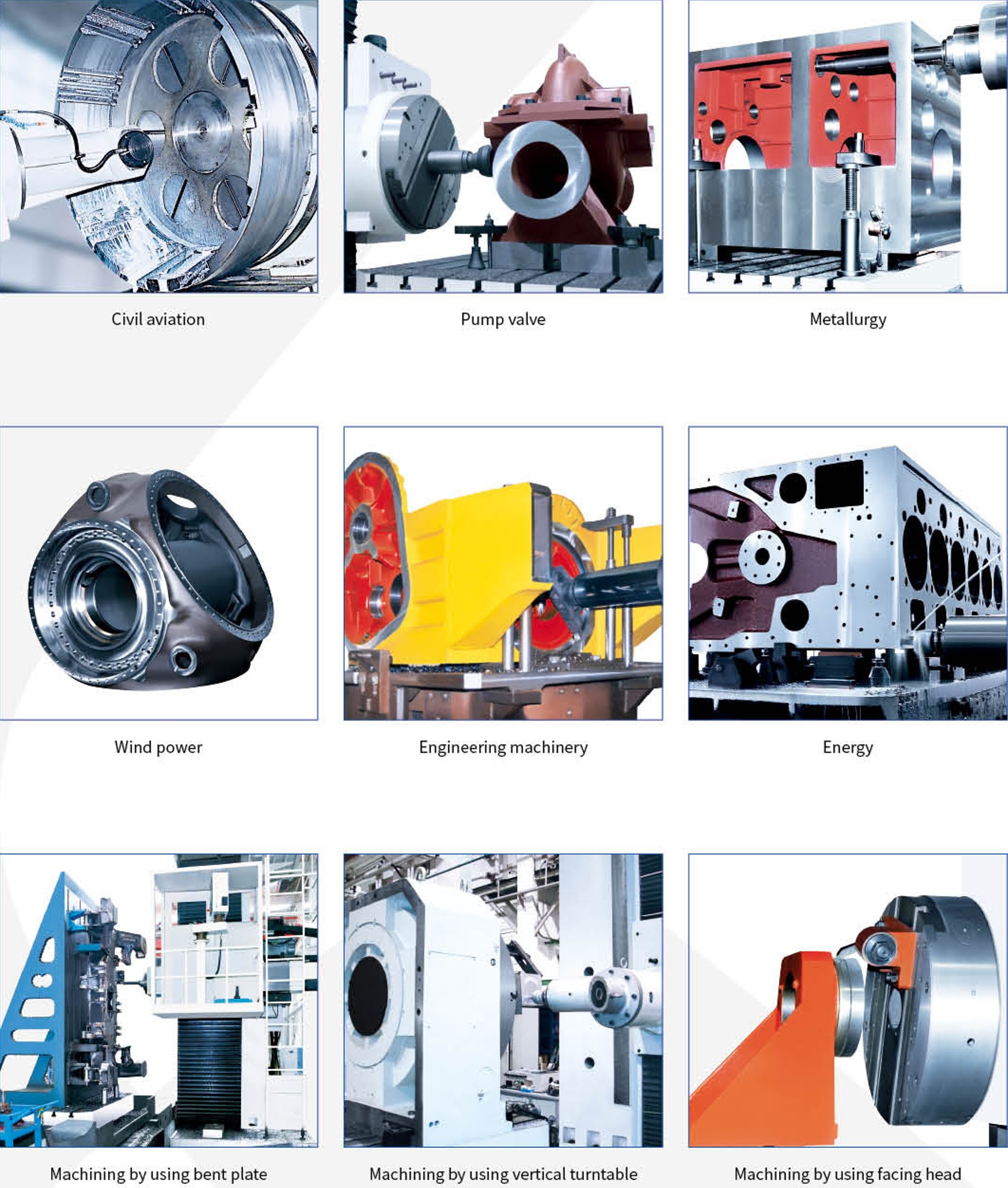

The machine tool features multiple machining functions such as boring, milling, drilling (drilling.expanding and reaming), tapping (rigid threading) and countersinking, and the excellent CNC system enables the machine tool to feature functions such as linear interpolation and circular interpolation.

Home » Products » MACHINES » CNC Boring and Milling Machine » PBC Series PBC110m PBC130m

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| ltems | Unit | PBC 110m | PBC 130m | ||

|---|---|---|---|---|---|

| Workbench dimension | mm | 1000×1250/ 1250×1400 | 1600×1800 | ||

| Maximum load of workbench | T | 5 | 10 | ||

| Spindle diameter | mm | φ110 | φ130 | ||

| Spindle taper hole | IS0 7:24 N0.50 | IS0 7:24 N0.50 | |||

| Tool shank specification | JT50/BT50 | JT50/BT50 | |||

| Spindle speed | r/min | 10-2500 | 10-3000 | ||

| Power of main motor | kW | 17/20.4 | 25/30 | ||

| Maximum torque of spindle | Nm | 1300/1600 | 2100/2600 | ||

| Transverse travel X of workbench | mm | 2000 | 2000/3000/4000 | ||

| Vertical travel Y of headstock | mm | 1500 | 1600/2000 | ||

| Longitudinal travelZ of column | mm | 1200 | 1600/2000 | ||

| Travel W of spindle | mm | 550 | 800 | ||

| Workbench rotation B | ° | 0.001×360 | 0.001×360 | ||

| Distance from spindle center to workbench | mm | 60-1560 | 100-1700 | ||

| Distance from spindle nose to workbench center | mm | 350 | 850 | ||

| Feeding speed | X、Y、Z | mm/min | 1-6000 | X/Z:1-12000,Y:10000 | |

| W | mm/min | 1-2000 | 1-3000 | ||

| B | r/min | 0-1 | 0-1.5 | ||

| Rapid speed | X、Y、Z | m/min | 9 | X/Z:12,Y:10 | |

| W | m/min | 2.4 | 3 | ||

| B | r/min | 2 | 1.5 | ||

| Positioning accuracy | X、Y、Z | mm | X:0.02/0.016(grating scale) | XZ:0.015/0.01(grating scale) | |

| YZ:0.018/0.015(grating scale) | Y:0.01(grating scale) | ||||

| W | mm | 0.02 | 0.012 | ||

| B | “ | 12/10(grating scale),4X90°;6 | 8(grating scale),4X90°;6 | ||

| Repositioning accuracy | X、Y、Z | mm | X:0.011 YZ:0.01 | 0.008 | |

| W | 0.016 | 0.01 | |||

| B | “ | 7 | 6 | ||

| CNC system | SIEMENS 828D | SIEMENS 828D | |||

- Imported dual-speed reducer for headstock

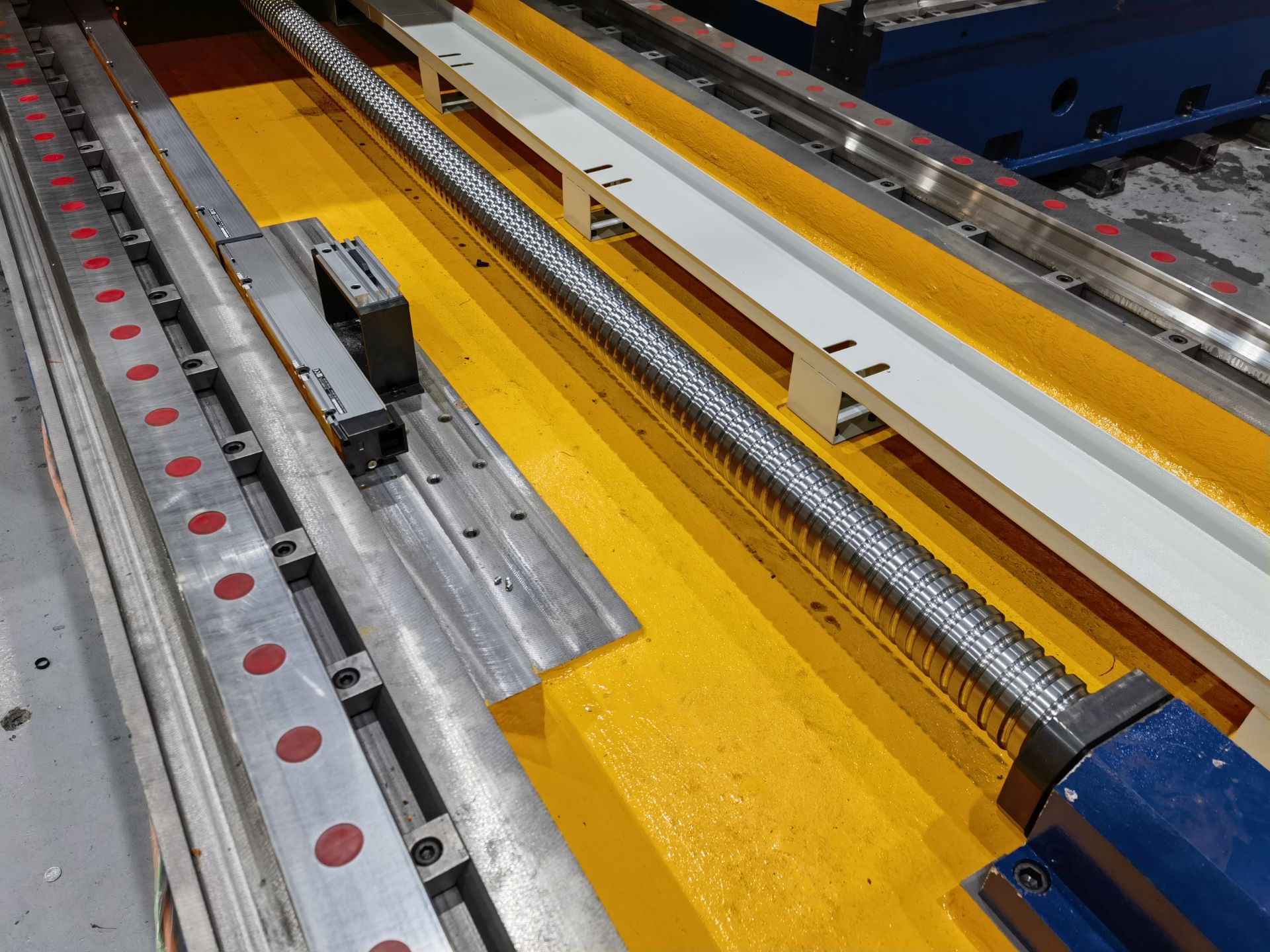

- Steel guiderail for transverse and longitudinabody

- Hard guiderail

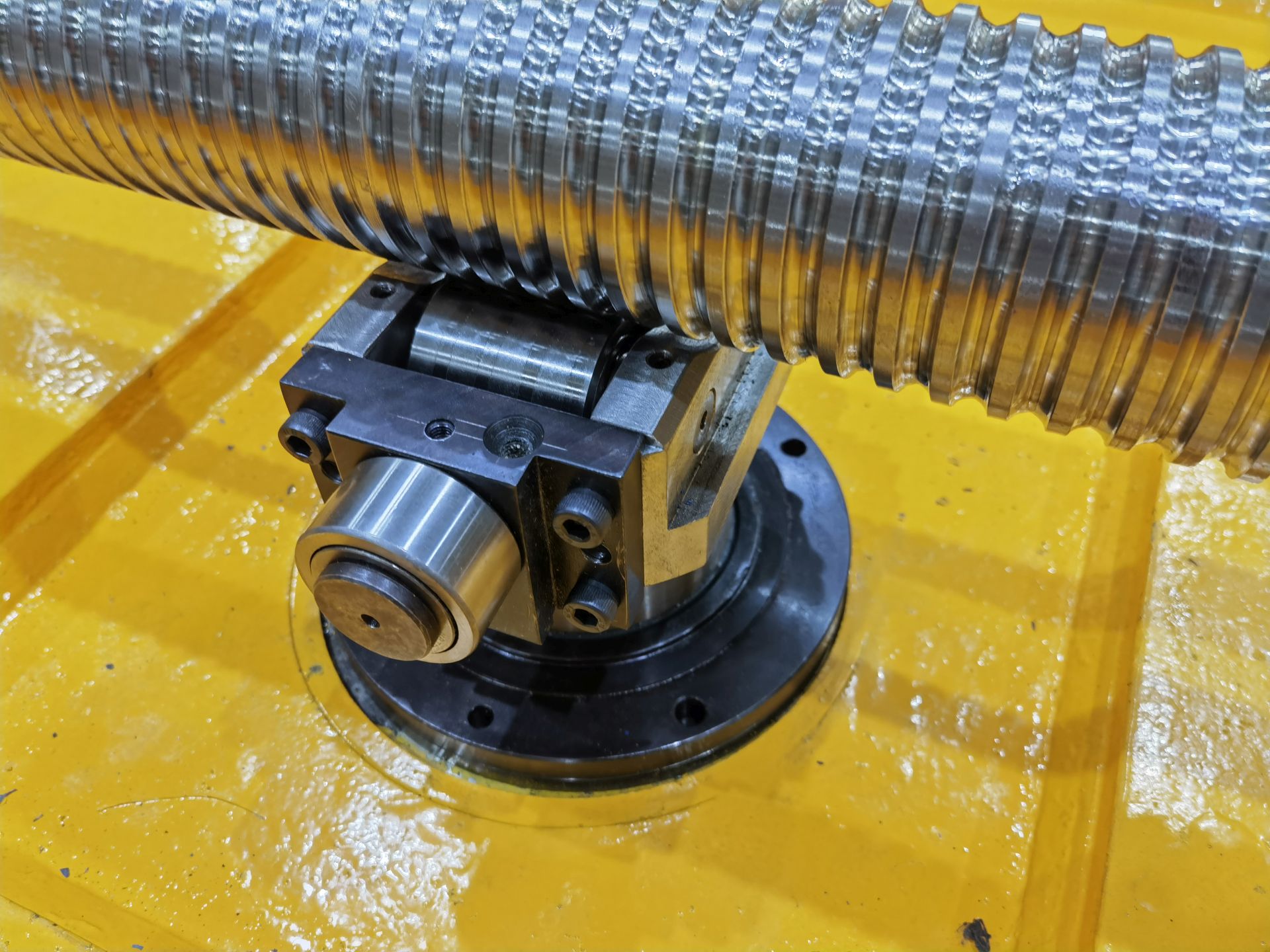

- Rotary workbench featuring double-motor drive

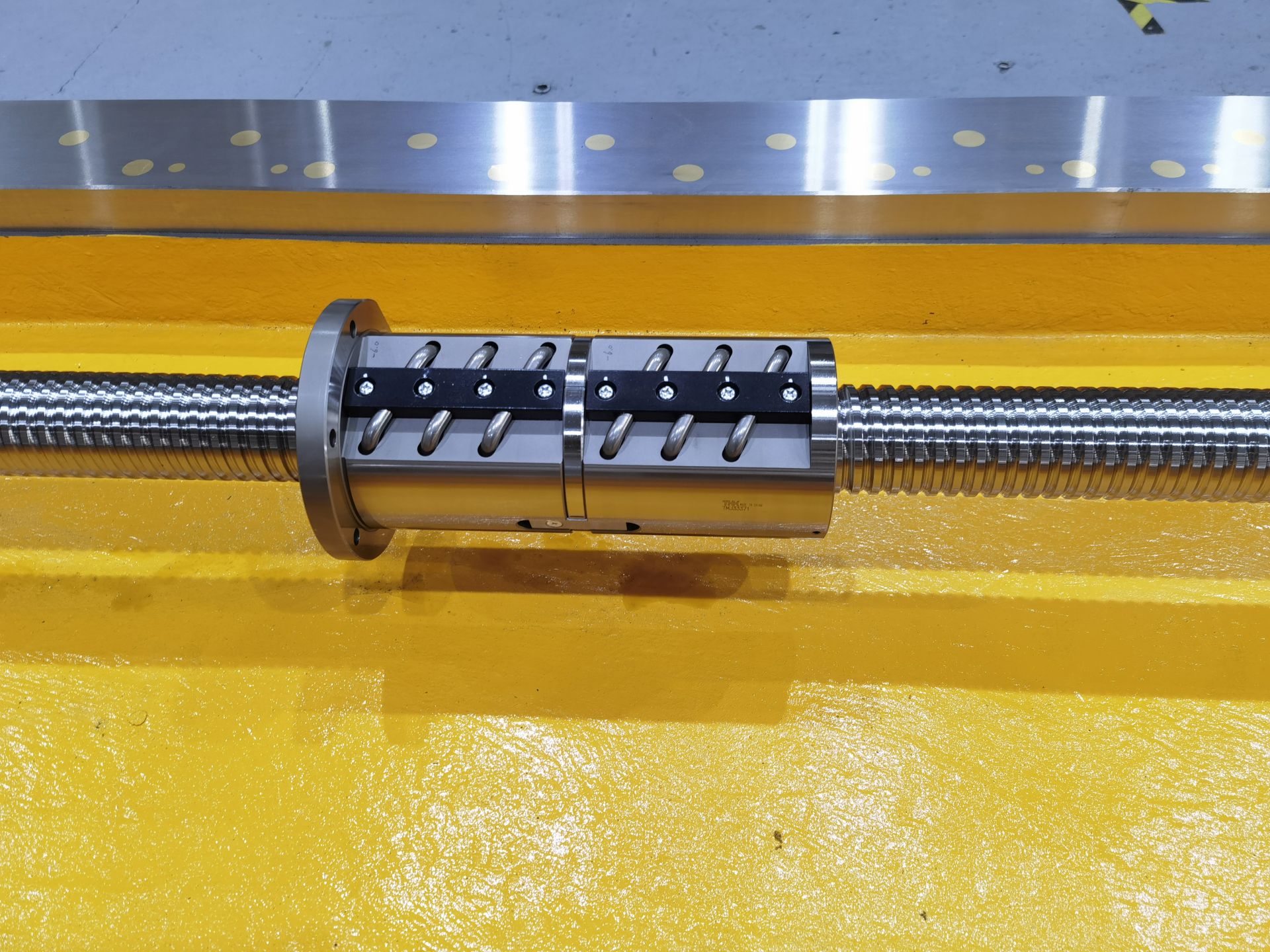

- THK high precision ballscrew

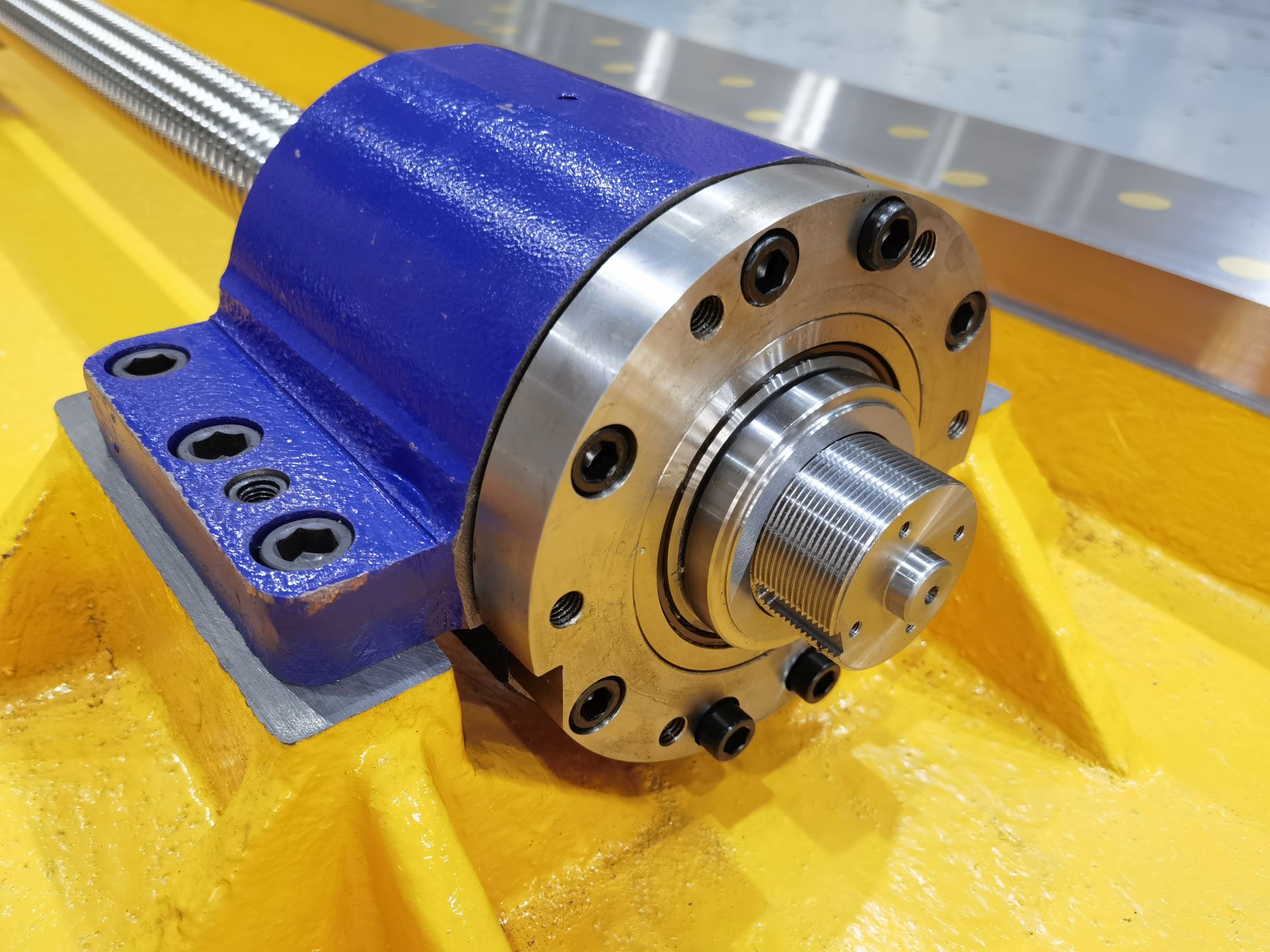

- Bearing

- HEIDENHAIN grating scale

- Lead screw support

- Hydraulic Station

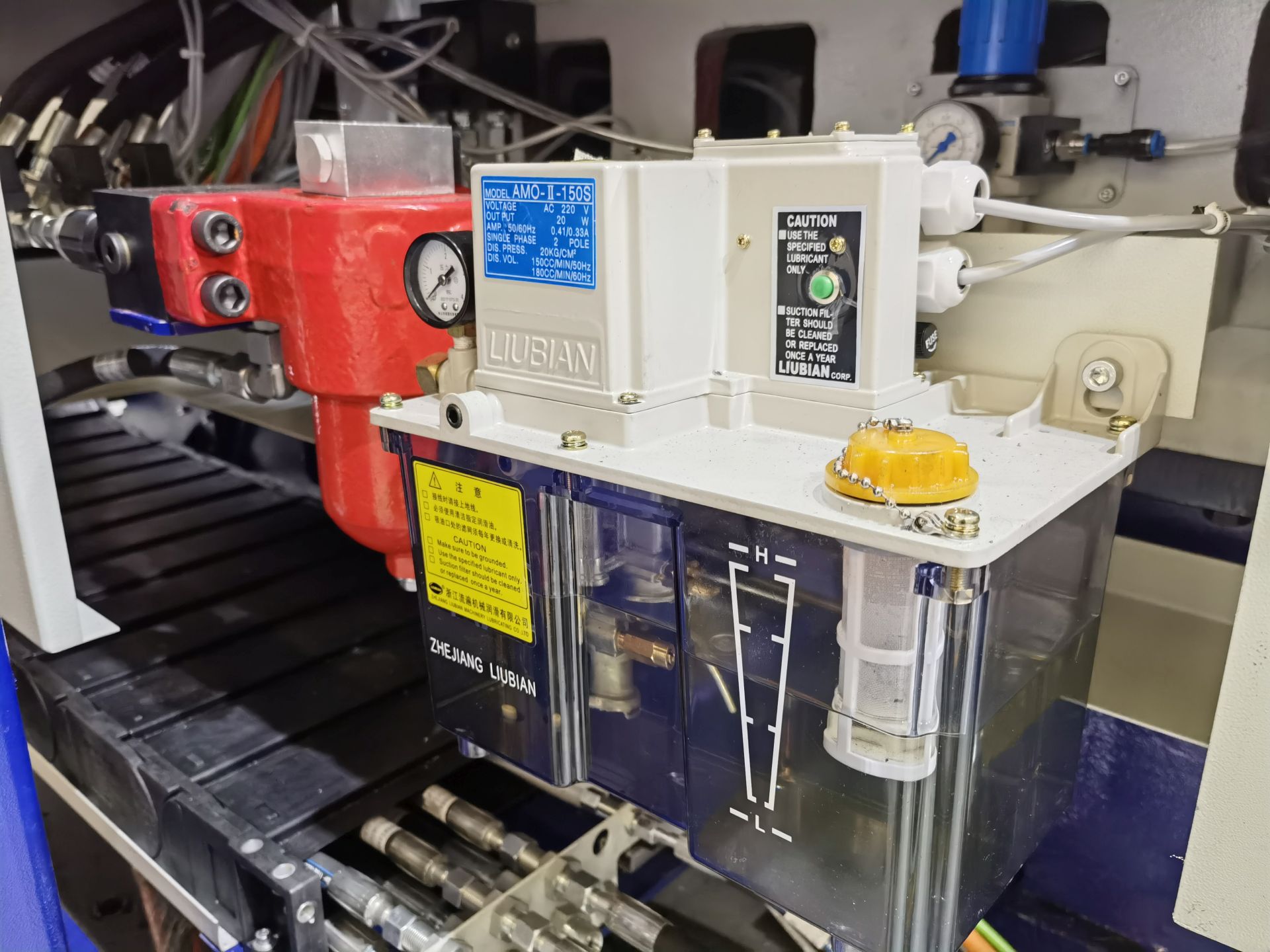

- Lubrication station

- Worktable

- Oil chiller

- Customizable CNC operating system

- Main motor