Home » Products » MACHINES » Conventional Machine Tool » Manual Horizontal Boring and Milling Machine » TPX6111B TPX6111B/2 TPX6111B/3

TPX6111B TPX6111B/2 TPX6111B/3

Home » Products » MACHINES » Conventional Machine Tool » Manual Horizontal Boring and Milling Machine » TPX6111B TPX6111B/2 TPX6111B/3

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| Item | Unit | TPX6111B | TPX6111B/2 | TPX6111B/3 | TPX6113 | TPX6113/2 | |

|---|---|---|---|---|---|---|---|

| Spindle | Diameter | mm | 110 | 110 | 110 | 130 | 130 |

| Taper | – | Morse No6 (ISO7:24No50) | Morse No6 (ISO7:24No50) | Morse No6 (ISO7:24No50) | Metric 80 (ISO7:24No50) | Metric 80 (ISO7:24No50) | |

| Max Torque | N.m | 1225 | 1225 | 1225 | 3136 | 3136 | |

| Max Axial Thrust | N | 12250 | 12250 | 12250 | 31360 | 31360 | |

| Speed Settings | – | 22 | 22 | 22 | 24 | 24 | |

| Speed Range | r/min | 8-1000 | 8-1000 | 8-1000 | 4-800 | 4-800 | |

| Main Motor Power | kW | 7.5 | 7.5 | 7.5 | 15 | 15 | |

| Facing Plate | Max Torque | N.m | 1960 | 1960 | 1960 | 4900 | 4900 |

| Diameter | mm | 600 | 600 | 600 | 750 | 750 | |

| Speed Range | r/min | 4-200 | 4-200 | 4-200 | 2.5-125 | 2.5-125 | |

| Speed Settings | – | 18 | 18 | 18 | 18 | 18 | |

| Worktable | Dimensions | mm | 1100×960 | 1100×960 | 1250×1100 | 1600×1400 | 1800×1600 |

| Max Load | kg | 5000 | 5000 | 5000 | 8000 | 10000 | |

| T-slot Size | mm | 22 | 22 | 22 | 28 | 28 | |

| T-slot Count | 一 | 7 | 7 | 7 | 9 | 11 | |

| Machining Range | X-axis Max Travel | mm | 900 | 1250 | 1600 | 1600 | 2000 |

| Y-axis Max Travel | mm | 900 | 900 | 1200 | 1400 | 1800 | |

| Z-axis Max Travel | mm | 1400 | 1400 | 1400 | 2000 | 2000 | |

| W-axis Max Travel(Spindle) | mm | 600 | 600 | 600 | 900 | 900 | |

| U-axis Max Travel(Facing Plate Slide) | mm | 180 | 180 | 180 | 250 | 250 | |

| B-axis Rotary Angle | 。 | 360 | 360 | 360 | 360 | 360 | |

| Min Distance Between Spindle Centerline and Worktable | mm | 0 | 0 | 0 | 0 | 0 | |

| Feed | Rapid Traverse | mm/min | X/Y/Z/W:2500 | X/Y/Z/W:2500 | X/Y/Z/W:2500 | X/Y/Z/W:2500 | X/Y/Z/W:2500 |

| Feed range of axes for each spindle revolution | mm/rev | 0.04-6/0.01-1.88 (X/Y/Z/W) | 0.04-6/0.01-1.88 (X/Y/Z/W) | 0.04-6/0.01-1.88 (X/Y/Z/W) | 0.05-8/0.01-2 (X/Y/Z/W) | 0.05-8/0.01-2 (X/Y/Z/W) | |

| Speed Range (X) | mm/min | – | – | – | – | – | |

| Accuracy | Linear Measurement Reading Accuracy (X/Y/Z-axis) | mm | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

| Linear Measurement Reading Accuracy (B-axis) | 。 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | |

| General Specs | Dimensions(LxWxH) | mm | 4910x2454x2750 | 4910x2870x2750 | 5028x3359x3079 | 6995x3647x3442 | 7030x4665x3800 |

| Machine Weight | kg | 11500 | 13000 | 14000 | 24000 | 28000 | |

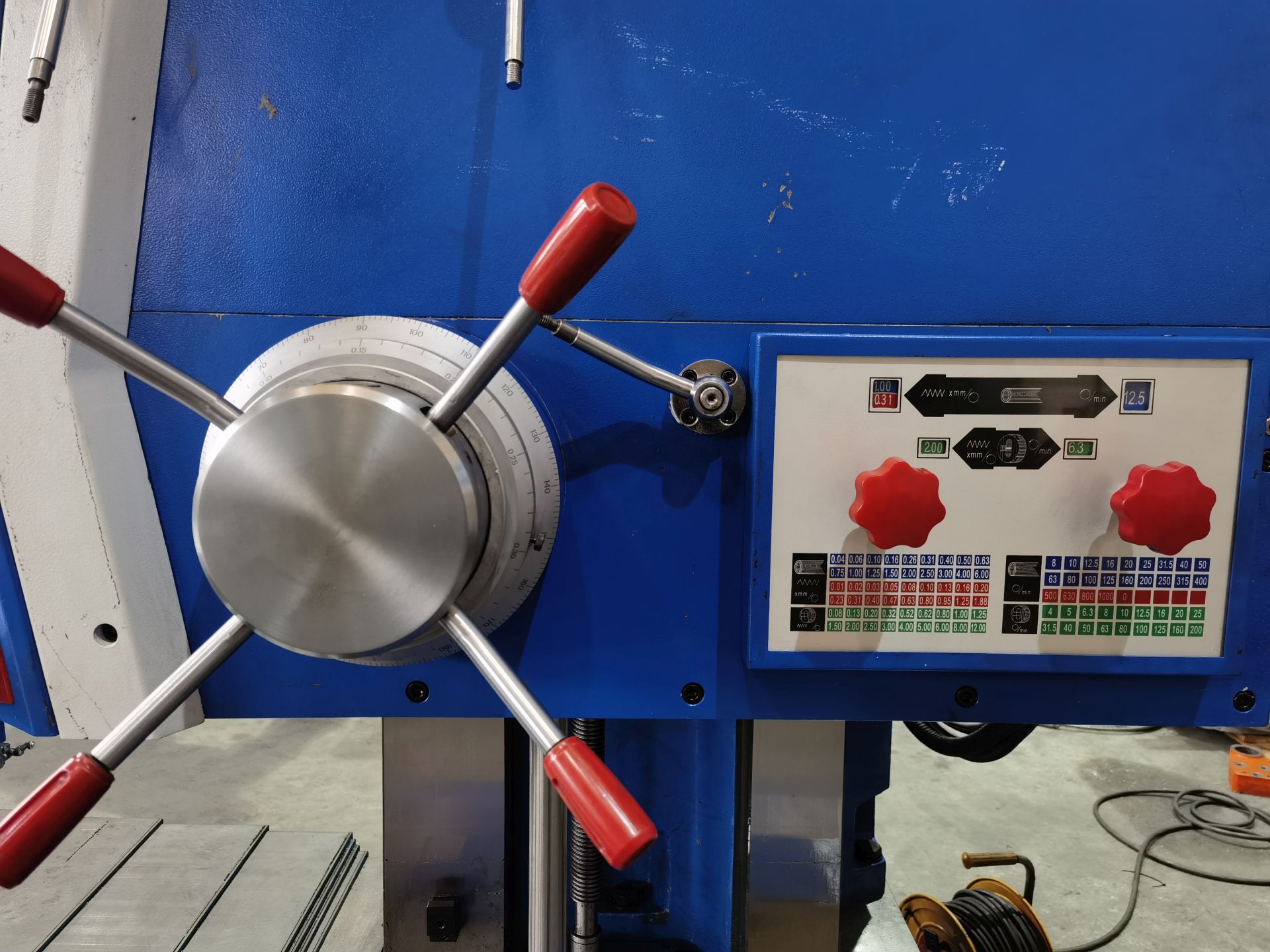

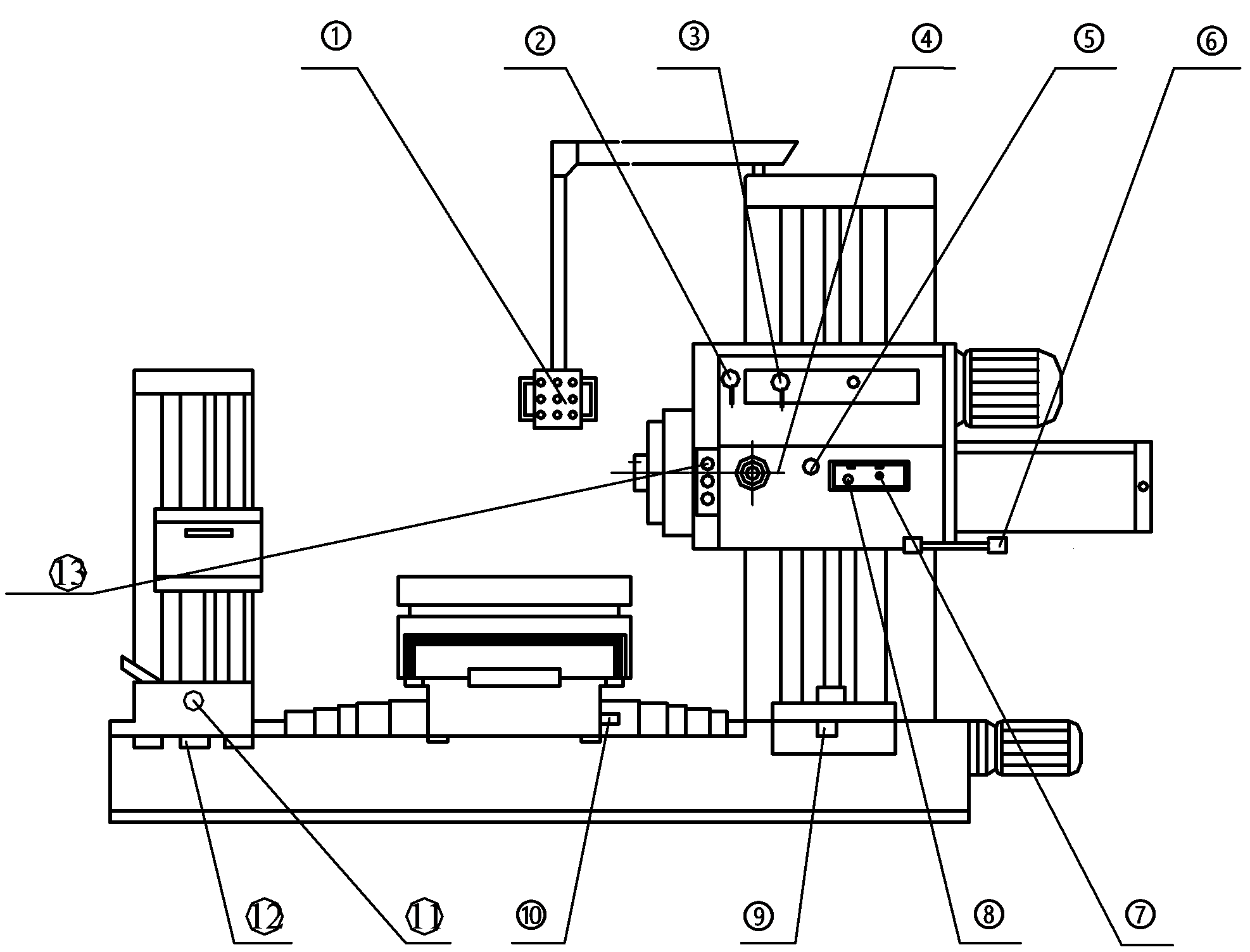

Arrangement of the operation system of the machine

| No. | Name of the operation mechanism |

|---|---|

| 1 | Button station |

| 2 | Lever for engaging and disengaging of the facing head rotation |

| 3 | Lever for forward and reverse feed |

| 4 | Distributing lever of auto,micro and spindle feed(including radial slide) |

| <br /> 5 | Distributing lever for the movement of spindle or radial slide on the facing head |

| 6 | Clamping lever of spindle |

| 7 | Rotating valve lever for the main movement speed change |

| 8 | Rotating lever for feed rate change |

| 9 | Lever hole for hand rough elevation of headstock |

| 10 | Lever hole for hand-driven rotation and longitudinal and cross movements of table |

| 11 | Lever hole for hand-driven longitudinal traverse and elevation of rear column |

| 12 | Clamping points of rear column (each points at back and front) |

| 13 | Distribution lever for longitudinal transverse of boring stay and elevation of boring stay slide |

| 14 | Emergency stop button(for 7:24 50#) |

| 15 | Tool unclamping button (for 7:24 50#) |

| 16 | Tool clamping button (for 7:24 50#) |

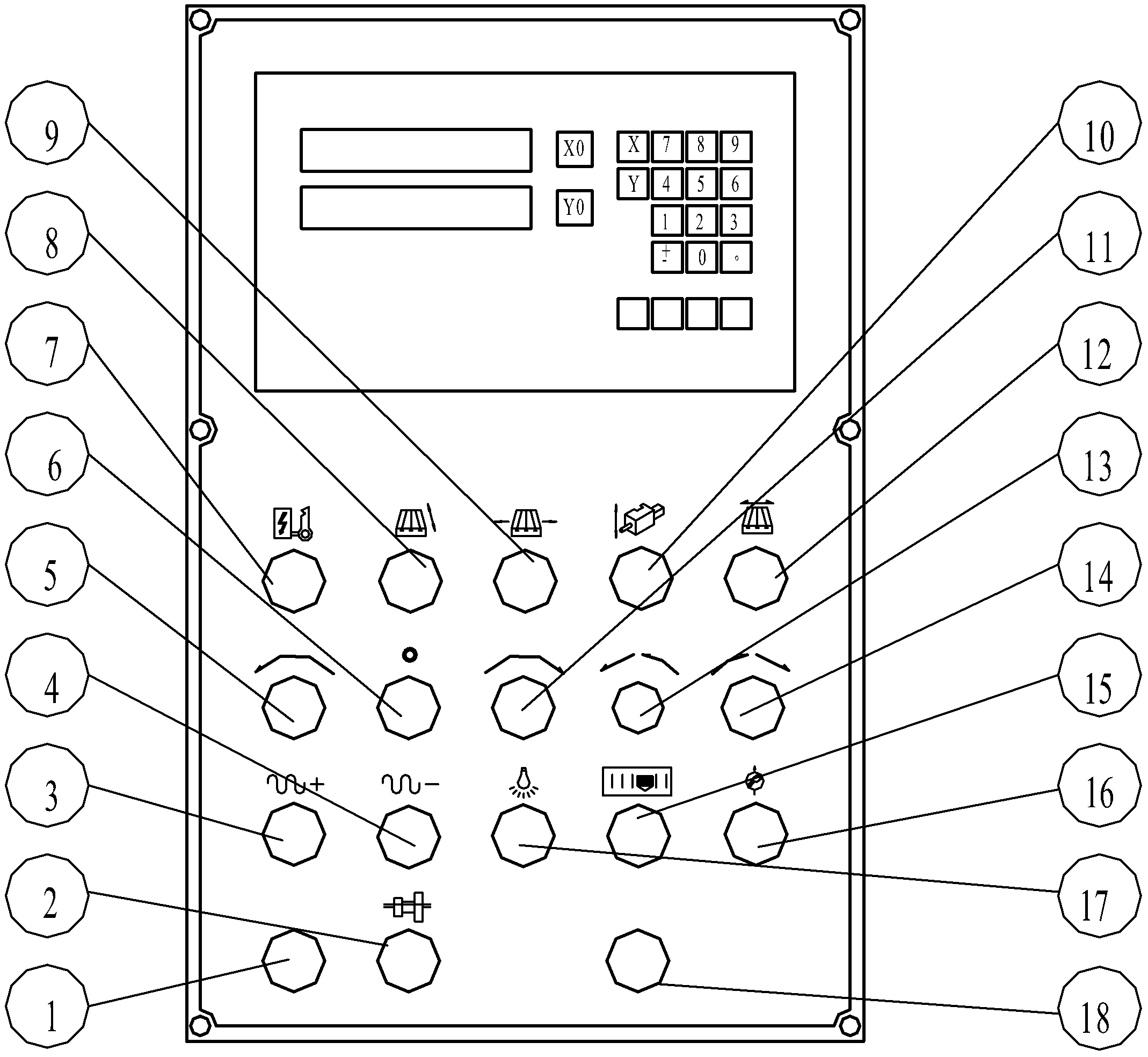

Arrangement of buttons and switches on the button station

| No. | Description |

|---|---|

| 1 | Power supply indicator |

| 2 | Button for executing speed change |

| 3 | Forward rapid button |

| 4 | Reverse rapid button |

| 5 | Button for spindle or facing head rotating positively |

| 6 | Button for stopping main motor |

| 7 | Key switch |

| 8 | Button for transverse movement of table(with indicator) |

| 9 | Button for longitudinal movement of table(with indicator) |

| 10 | Button for lifting movement of headstock(with indicator) |

| 11 | Button for spindle or facing head rotating negtively |

| 12 | Button for rotation of table(with indicator) |

| 13 | Button for forward inching of spindle or facing head |

| 14 | Button for reverse inching of spindle or facing head |

| 15 | Button for optical illumination |

| 16 | Push-button for lubrication guideways |

| 17 | Switch for illuminating lamp |

| 18 | Emergency stop button |

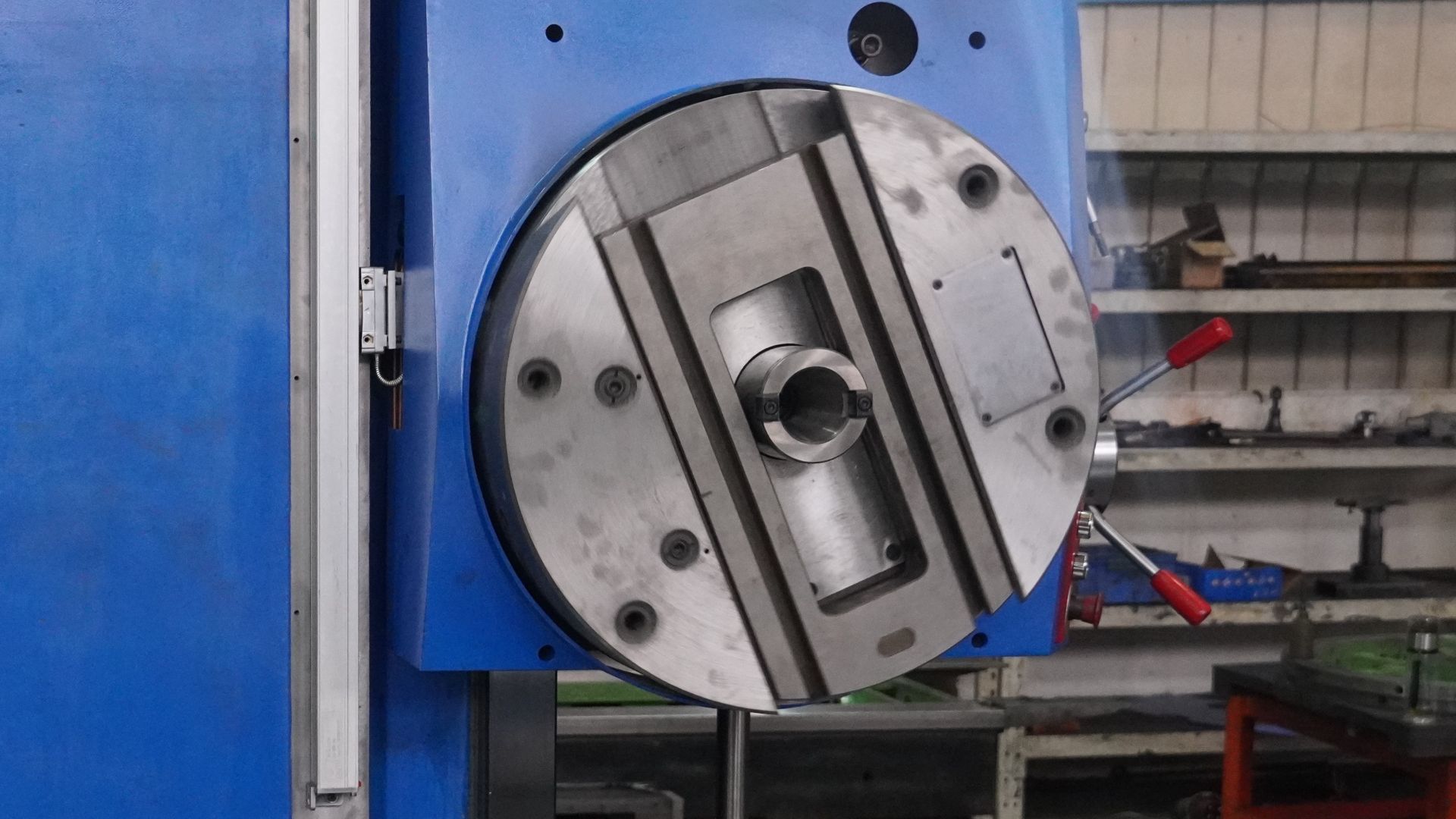

- Spindle

- Operator Panel

- Worktable

- Spindle Control Structure

- Spindle Box Lifting Screw

- Lubrication Station

- Main Motor and Oil Pump Motor

- Worktable Transmission Device

- Rear Column Support Lifting

- Electrical Distribution Box