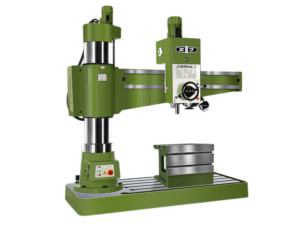

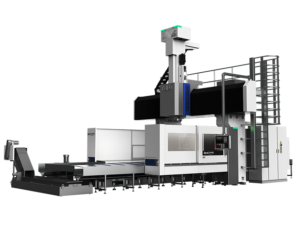

Home » Products » MACHINES » Conventional Machine Tool » Manual Horizontal Boring and Milling Machine » TPX6113 TPX6113/2

TPX6113 TPX6113/2

The TPX series horizontal milling and boring machines are based ona classic design, suitable for rough and finished boring, capable ofmilling large and box type components. They excel at inner hold boringcylindrical turning and grooving by radial feed of facing plate. A 4x90optical positioning device allows for machining accuracy when turninglarge pieces. The precision digital read out measurement systemsensures accuracy of coordinates and lineation.

* Machine bed with larger specifications is added with integral auxiliary guideway

* Spindle system consists of three-layer structure, facing head spindle, hollow spindle and boring spindle

* The spindle with disk spring clamping and hydraulic unclamping makes tool handling easy

Home » Products » MACHINES » Conventional Machine Tool » Manual Horizontal Boring and Milling Machine » TPX6113 TPX6113/2

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| Model | TPX6113 | TPX6113/2 | ||||||

|---|---|---|---|---|---|---|---|---|

| Spindle Dia.(mm) | 130 | 130 | ||||||

| Max.Spindle torque (NM) | 2950 | 2950 | ||||||

| Max. Facing head torque(NM) | 4694 | 4694 | ||||||

| Max. Spindle axial resistance (N) | 31360 | 31360 | ||||||

| Spindle taper | 7:24 50# | 7:24 50# | ||||||

| Worktabel travel | Long. | With rear column | 1500 | 1500(Special) | ||||

| Without rear column | 2000(Special) | 2000 | ||||||

| Cross | 1600 | 2000 | ||||||

| Distance from spindle centerline to worktable surface | 0-1400 | 0-1800 | ||||||

| Max.spindle travel | 900mm | 900mm | ||||||

| Max.radial travel of facing head | 250mm | 250mm | ||||||

| Load capacity(kg) | Worktable at middle of slide | 8000 | 10000 | |||||

| Worktable at ends of slide | 6300 | 7000 | ||||||

| Spindle speed range | 8-800r/min | 8-800r/min | ||||||

| Facing head speed range | 2.5-125r/min | 2.5-125r/min | ||||||

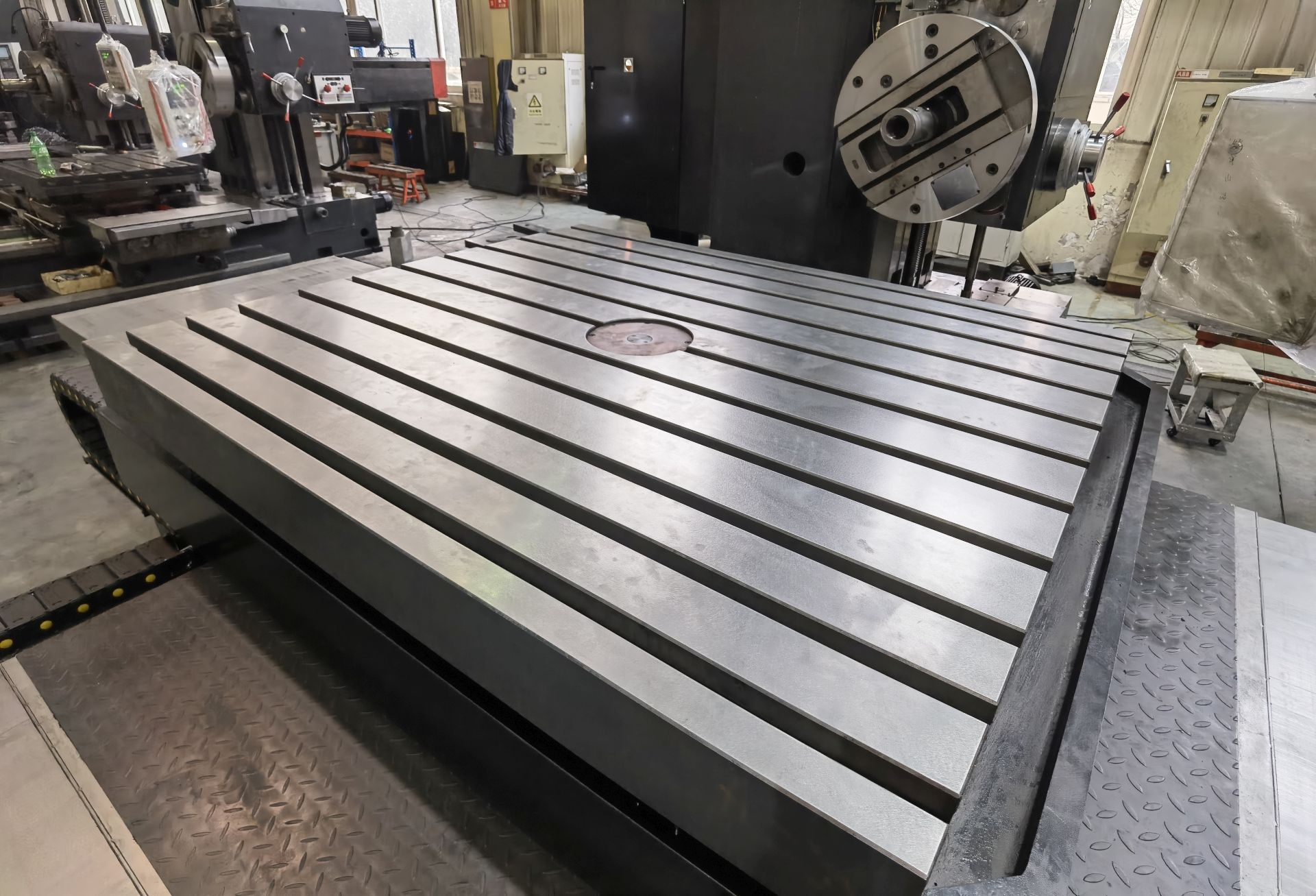

| Worktable area(LxW) | 1600×1400(mm) | 1800×1600(mm) | ||||||

| Worktable rapid rotary speed | 1.2r/min | 1.2r/min | ||||||

| Feed range of facing head slide | 1-1560mm/min | 1-1560mm/min | ||||||

| Reading accuracy of measure system | 0.01mm | 0.01mm | ||||||

| Boring accuracy and surface roughness | IT7,surface roughness within 3.2-1.6 | IT7,surface roughness within 3.2-1.6 | ||||||

| Machine size(LxWxH) | 6995x3647x3442(mm) | 7030x4665x3800(mm) | ||||||

| Machine weight(Kg) | 24000 | 28000 | ||||||

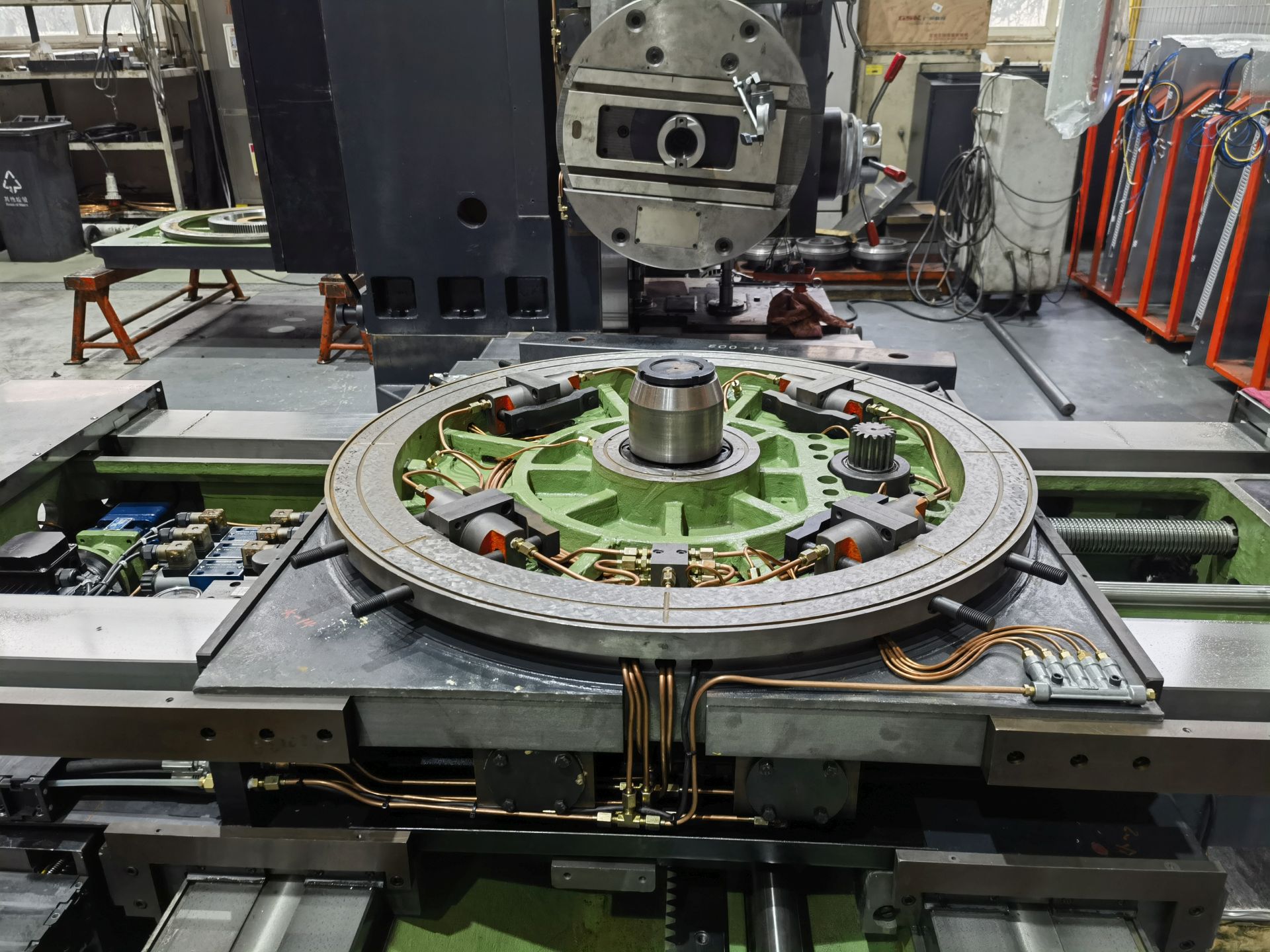

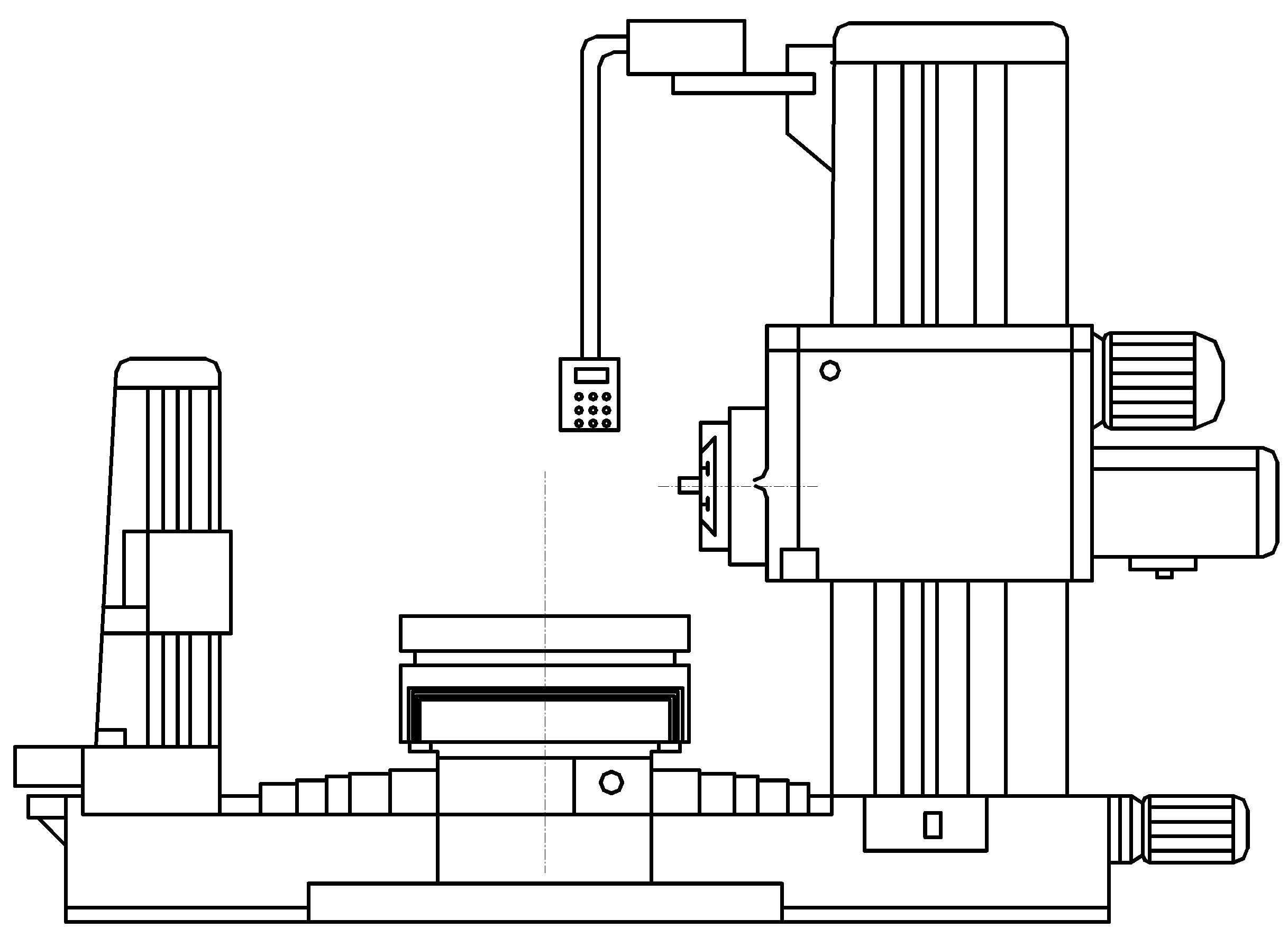

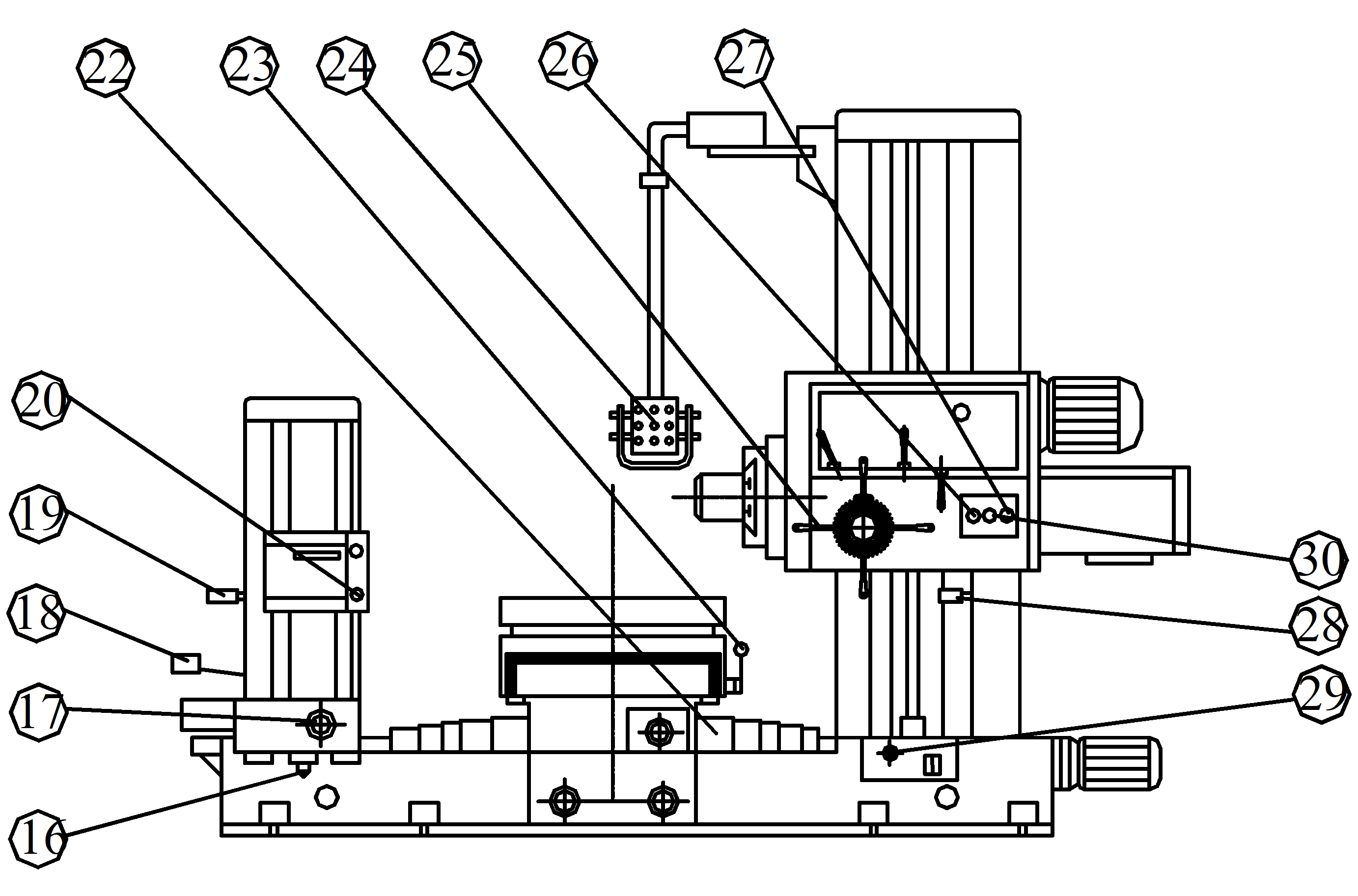

Layout of the Machine

Name of controls

| No. | Name of controls |

|---|---|

| 16 | Screws for clamping the rear column |

| 17 | Hand lever hole for hand traversing the rear column longitudinally and boring bar bearing |

| 18 | Distributing hand lever for selecting the traverse of rear column and boring bar bearing |

| 19 | Handle for fine hand adjustment for boring bar bearing |

| 20 | Screws for clamping the boring bar bearing |

| 22 | Hand lever hole for hand traversing the cross and longitudinal saddles and rotary motion of the table |

| 23 | Hand lever for controlling the position pin of rotary table |

| 24 | Pendant operator panel for controlling the machine |

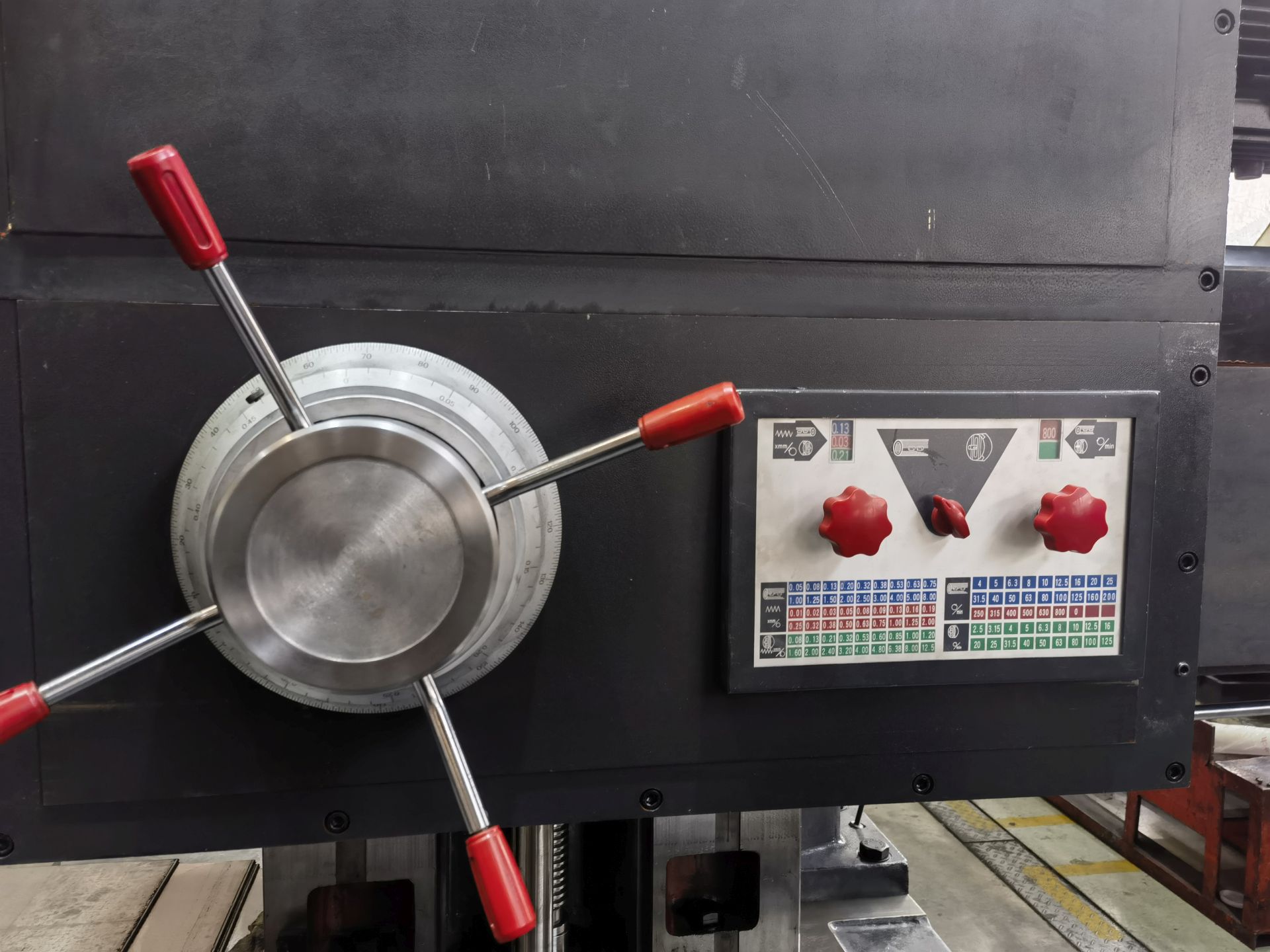

| 25 | Distributing turnstile for hand traversing of the spindle, fine adjustment and power feed |

| 26 | Feed speed change rotary valve |

| 27 | Speed change rotary valve for main motion |

| 28 | Hand lever for clamping the spindle |

| 29 | Hand lever hole for vertically traversing of the headstock |

| 30 | Rotary valve for selecting the movement of spindle or facing head (only used in horizontal boring machine with fixed facing head) |

- Spindle

- Operator Panel

- Worktable

- Spindle Control Structure

- Spindle Box Lifting Screw

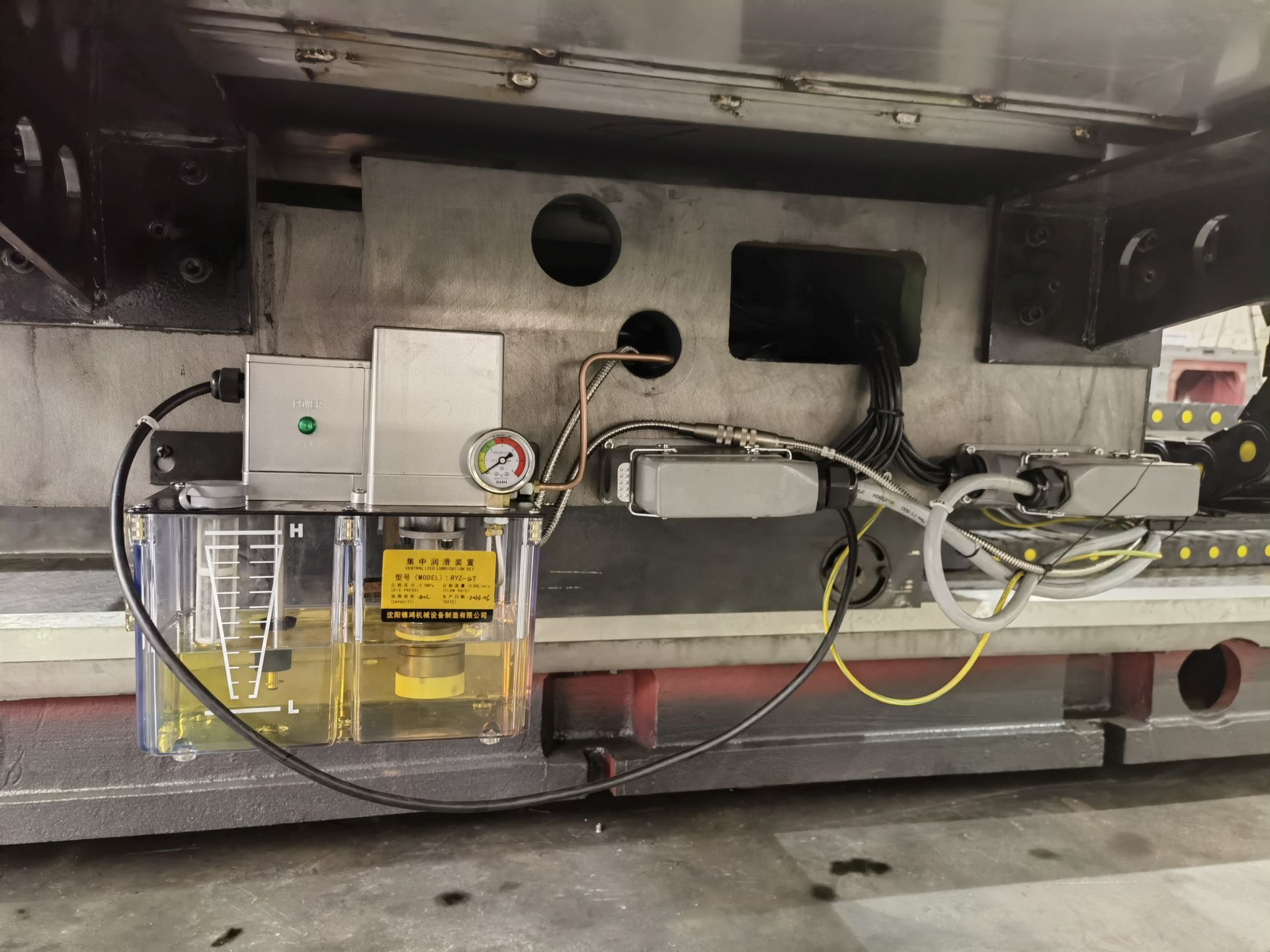

- Lubrication Station

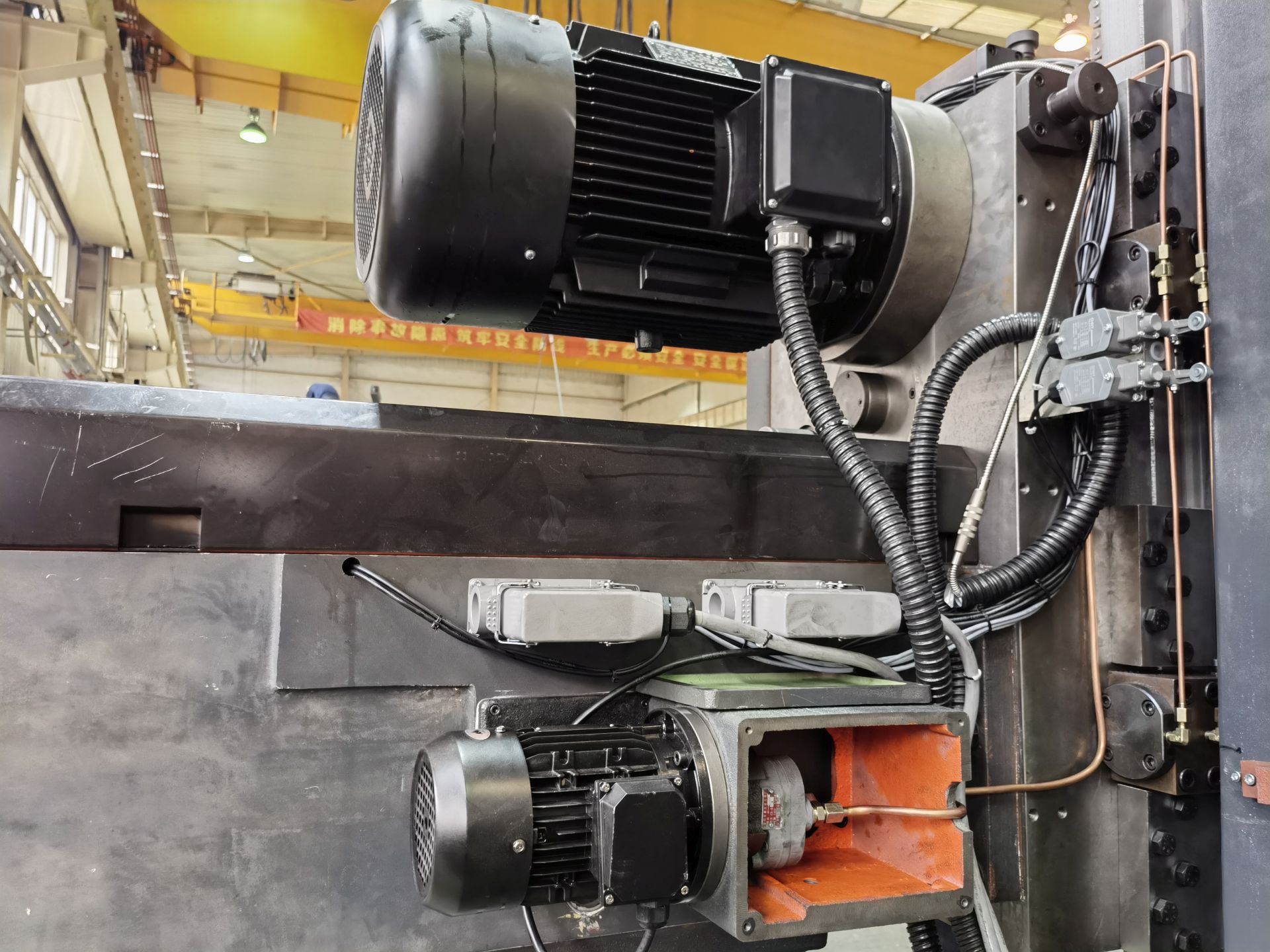

- Main Motor and Oil Pump Motor

- Worktable Transmission Device

- Rotary Mechanism for the Worktable