Home » Products » MACHINES » Conventional Machine Tool » Manual Lathe Machine » CA6140A,CA6150A,CA6140B/A,CA6150B/A

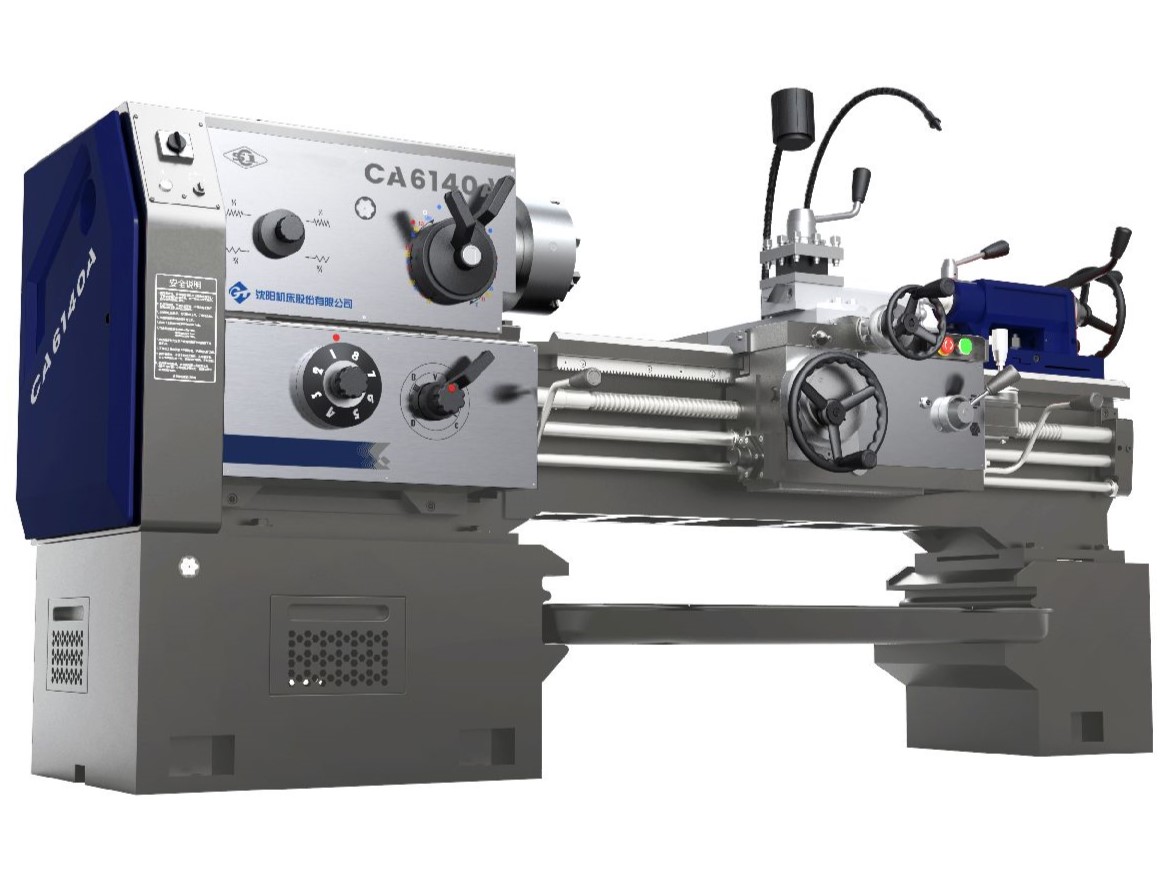

CA6140A,CA6150A,CA6140B/A,CA6150B/A

1. Versatile Turning Capability: Handles internal and external cylindrical surfaces, conical surfaces, rotating surfaces, end faces, and various threads (metric, inch, modular, and radial pitch threads). Can also drill holes, ream holes, and create oil grooves.

2. Materials Processing: Capable of processing steel, cast iron, and nonferrous metals.

3. Precision Machining: Achieves high dimensional accuracy up to IT7 level and smooth surface finishes.

4. Saddle Lathe Features: Suitable for turning flat and irregularly shaped parts in addition to standard turning work.

5. Manual Braking Function: Equipped with a convenient, sensitive, and reliable manual braking system for operational control and safety.

Home » Products » MACHINES » Conventional Machine Tool » Manual Lathe Machine » CA6140A,CA6150A,CA6140B/A,CA6150B/A

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| Parameter | Unit | CA6140A 750mm | CA6140A 1000mm | CA6140A 1500mm | CA6140A 2000mm | CA6150A 1000mm | CA6150A 1500mm | CA6150A 2000mm | CA6140B/A 1000mm | CA6140B/A 1500mm | CA6140B/A 2000mm | A6150B/A 1000mm | A6150B/A 1500mm | A6150B/A 2000mm | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Maximum Workpiece Slewing Diameter (Bed) | mm | Φ400 | Φ400 | Φ400 | Φ400 | Φ500 | Φ500 | Φ500 | Φ400 | Φ400 | Φ400 | Φ500 | Φ500 | Φ500 | ||||||||||||||

| Maximum Workpiece Slewing Diameter (Tool Holder) | mm | Φ210 | Φ210 | Φ210 | Φ210 | Φ300 | Φ300 | Φ300 | Φ210 | Φ210 | Φ210 | Φ300 | Φ300 | Φ300 | ||||||||||||||

| Maximum Workpiece Length / Maximum Cutting Length | mm | 750/650 | 1000/900 | 1500/1400 | 2000/1900 | 1000/900 | 1500/1400 | 2000/1900 | 1000/900 | 1500/1400 | 2000/1900 | 1000/900 | 1500/1400 | 2000/1900 | ||||||||||||||

| Width and Hardness of Bed | mm / Rc | 400, Rc52 | 400, Rc52 | 400, Rc52 | 400, Rc52 | 400, Rc52 | 400, Rc52 | 400, Rc52 | 400, Rc52 | 400, Rc52 | 400, Rc52 | 400, Rc52 | 400, Rc52 | 400, Rc52 | ||||||||||||||

| Size of Tool Bar Section Dimensions | mm | 25×25 | 25×25 | 25×25 | 25×25 | 25×25 | 25×25 | 25×25 | 25×25 | 25×25 | 25×25 | 25×25 | 25×25 | 25×25 | ||||||||||||||

| Spindle | ||||||||||||||||||||||||||||

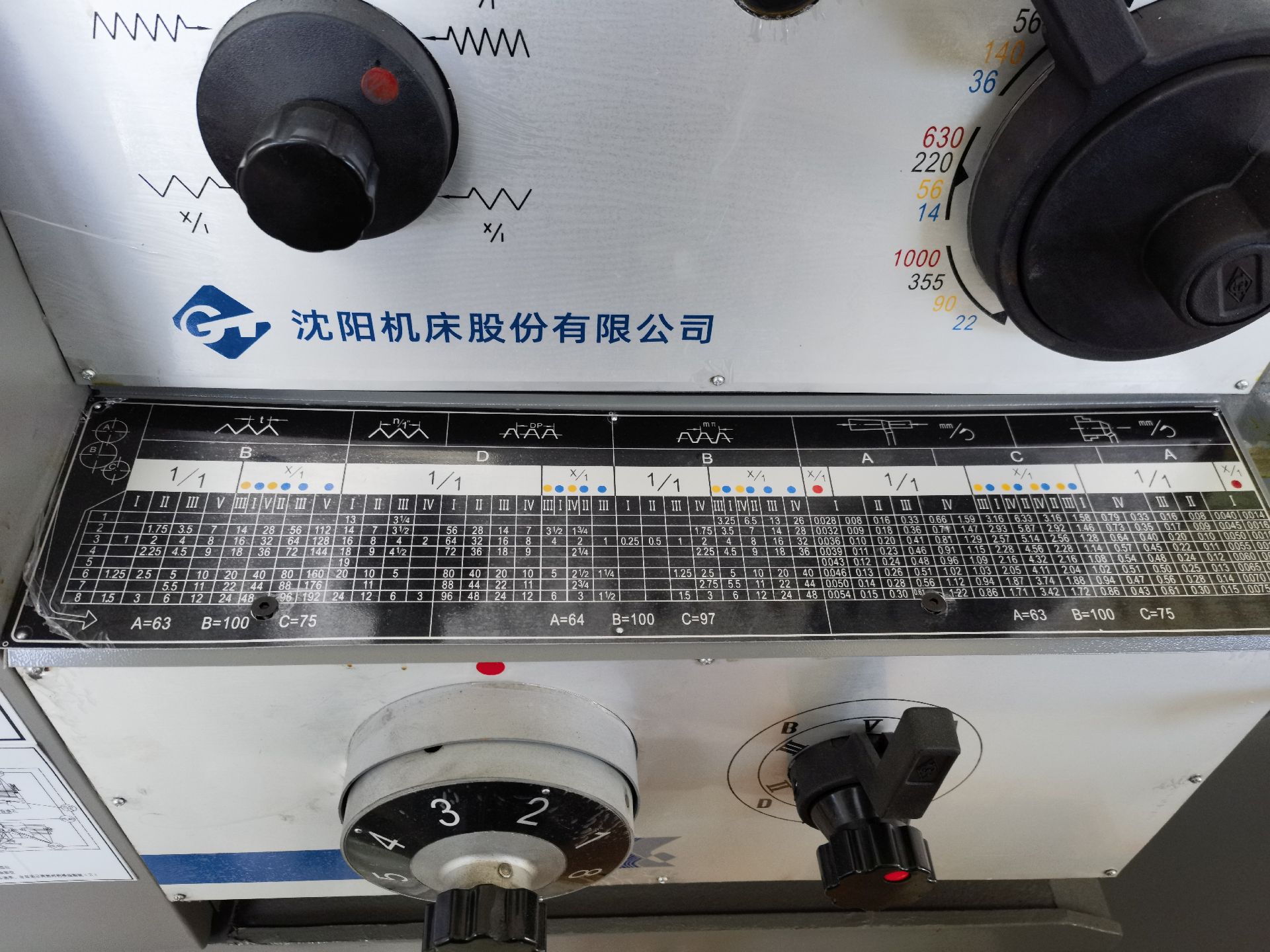

| Spindle Speed Range (Co-rotation) | r/min | 11-1600 (24) | 11-1600 (24) | 11-1600 (24) | 11-1600 (24) | 11-1600 (24) | 11-1600 (24) | 11-1600 (24) | 10-1400 (24) | 10-1400 (24) | 10-1400 (24) | 10-1400 (24) | 10-1400 (24) | 10-1400 (24) | ||||||||||||||

| Spindle Speed Range (Reverse) | r/min | 14-1580 (12) | 14-1580 (12) | 14-1580 (12) | 14-1580 (12) | 14-1580 (12) | 14-1580 (12) | 14-1580 (12) | 14-1580 (12) | 14-1580 (12) | 14-1580 (12) | 14-1580 (12) | 14-1580 (12) | 14-1580 (12) | ||||||||||||||

| Inner Hole of Spindle and Type and Code of Spindle End | mm | Φ52, A6 | Φ52, A6 | Φ52, A6 | Φ52, A6 | Φ52, A6 | Φ52, A6 | Φ52, A6 | Φ80, A28 | Φ80, A28 | Φ80, A28 | Φ80, A28 | Φ80, A28 | Φ80, A28 | ||||||||||||||

| Tapered Hole at Front End of Spindle | – | Mohs 6# | Mohs 6# | Mohs 6# | Mohs 6# | Mohs 6# | Mohs 6# | Mohs 6# | Φ90mm(1:20) | Φ90mm(1:20) | Φ90mm(1:20) | Φ90mm(1:20) | Φ90mm(1:20) | Φ90mm(1:20) | ||||||||||||||

| Feeding | ||||||||||||||||||||||||||||

| Spindle Longitudinal Feed per Revolution (64 Kinds) | ||||||||||||||||||||||||||||

| Standard | mm/r | 0.08-1.59 | 0.08-1.59 | 0.08-1.59 | 0.08-1.59 | 0.08-1.59 | 0.08-1.59 | 0.08-1.59 | 0.11-1.6 | 0.11-1.6 | 0.11-1.6 | 0.11-1.6 | 0.11-1.6 | 0.11-1.6 | ||||||||||||||

| Decrease feed | mm/r | 0.028-0.054 | 0.028-0.055 | 0.028-0.056 | 0.028-0.057 | 0.028-0.054 | 0.028-0.054 | 0.028-0.054 | 0.028-0.11 | 0.028-0.11 | 0.028-0.11 | 0.028-0.11 | 0.028-0.11 | 0.028-0.11 | ||||||||||||||

| Increase feed | mm/r | 1.71-6.33 | 1.71-6.33 | 1.71-6.33 | 1.71-6.33 | 1.71-6.33 | 1.71-6.33 | 1.71-6.33 | 1.76-6.4 | 1.76-6.4 | 1.76-6.4 | 1.76-6.4 | 1.76-6.4 | 1.76-6.4 | ||||||||||||||

| Spindle Transverse Feed per Revolution (64 Kinds) | ||||||||||||||||||||||||||||

| Standard | mm/r | 0.04-0.79 | 0.04-0.79 | 0.04-0.79 | 0.04-0.79 | 0.04-0.79 | 0.04-0.79 | 0.04-0.79 | 0.05-0.8 | 0.05-0.8 | 0.05-0.8 | 0.05-0.8 | 0.05-0.8 | 0.05-0.8 | ||||||||||||||

| Decrease feed | mm/r | 0.014-0.027 | 0.014-0.027 | 0.014-0.027 | 0.014-0.027 | 0.014-0.027 | 0.014-0.027 | 0.014-0.027 | 0.014-0.05 | 0.014-0.05 | 0.014-0.05 | 0.014-0.05 | 0.014-0.05 | 0.014-0.05 | ||||||||||||||

| Increase feed | mm/r | 0.86-3.16 | 0.86-3.16 | 0.86-3.16 | 0.86-3.16 | 0.86-3.16 | 0.86-3.16 | 0.86-3.16 | 0.88-3.2 | 0.88-3.2 | 0.88-3.2 | 0.88-3.2 | 0.88-3.2 | 0.88-3.2 | ||||||||||||||

| Tool Holder | ||||||||||||||||||||||||||||

| Tool Holder Transverse Stroke | mm | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | ||||||||||||||

| Small Tool Holder Distance Traveled | mm | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | ||||||||||||||

| Rotation Angle of Tool Holder Turntable | ° | ±90 | ±90 | ±90 | ±90 | ±90 | ±90 | ±90 | ±90 | ±90 | ±90 | ±90 | ±90 | ±90 | ||||||||||||||

| Rapid Traverse Speed of Tool Holder (Longitudinal) | m/min | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | ||||||||||||||

| Rapid Traverse Speed of Tool Holder (Transverse) | m/min | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | ||||||||||||||

| Tail-stock | ||||||||||||||||||||||||||||

| Maximum Stroke of the Tail-stock Spindle | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | ||||||||||||||

| Tail-stock Spindle Diameter | mm | Φ75 | Φ75 | Φ75 | Φ75 | Φ75 | Φ75 | Φ75 | Φ75 | Φ75 | Φ75 | Φ75 | Φ75 | Φ75 | ||||||||||||||

| Taper of Tail-stock Spindle Hole | – | Mohs 5# | Mohs 5# | Mohs 5# | Mohs 5# | Mohs 5# | Mohs 5# | Mohs 5# | Mohs 5# | Mohs 5# | Mohs 5# | Mohs 5# | Mohs 5# | Mohs 5# | ||||||||||||||

| Range of Processing Thread | ||||||||||||||||||||||||||||

| Metric Thread (Kinds) | mm | 1-192 (44) | 1-192 (44) | 1-192 (44) | 1-192 (44) | 1-192 (44) | 1-192 (44) | 1-192 (44) | 1-192 (44) | 1-192 (44) | 1-192 (44) | 1-192 (44) | 1-192 (44) | 1-192 (44) | ||||||||||||||

| Inch Thread (Kinds) | t.p.i | 2-24 (21) | 2-24 (21) | 2-24 (21) | 2-24 (21) | 2-24 (21) | 2-24 (21) | 2-24 (21) | 2-24 (21) | 2-24 (21) | 2-24 (21) | 2-24 (21) | 2-24 (21) | 2-24 (21) | ||||||||||||||

| Modular Thread (Kinds) | mm | 0.25-48 (39) | 0.25-48 (39) | 0.25-48 (39) | 0.25-48 (39) | 0.25-48 (39) | 0.25-48 (39) | 0.25-48 (39) | 0.25-48 (39) | 0.25-48 (39) | 0.25-48 (39) | 0.25-48 (39) | 0.25-48 (39) | 0.25-48 (39) | ||||||||||||||

| Pitch Thread (Kinds) | D.P | 1-96 (37) | 1-96 (37) | 1-96 (37) | 1-96 (37) | 1-96 (37) | 1-96 (37) | 1-96 (37) | 1-96 (38) | 1-96 (38) | 1-96 (38) | 1-96 (38) | 1-96 (38) | 1-96 (38) | ||||||||||||||

| Main Motor Power | KW | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | ||||||||||||||

| Machine Tool Net Weight | kg | 1990 | 2070 | 2220 | 2570 | 2140 | 2290 | 2640 | 2070 | 2220 | 2570 | 2140 | 2290 | 2640 | ||||||||||||||

| Machine Dimensions(Length × Width × Height) | mm | 2418×1000×1267 | 2668×1000×1270 | 3168×1000×1270 | 3668×1000×1270 | 2668×1037×1312 | 3168×1037×1312 | 3668×1037×1312 | 2668×1000×1270 | 3168×1000×1270 | 3668×1000×1270 | 2668×1037×1315 | 3168×1037×1315 | 3668×1037×1315 | ||||||||||||||

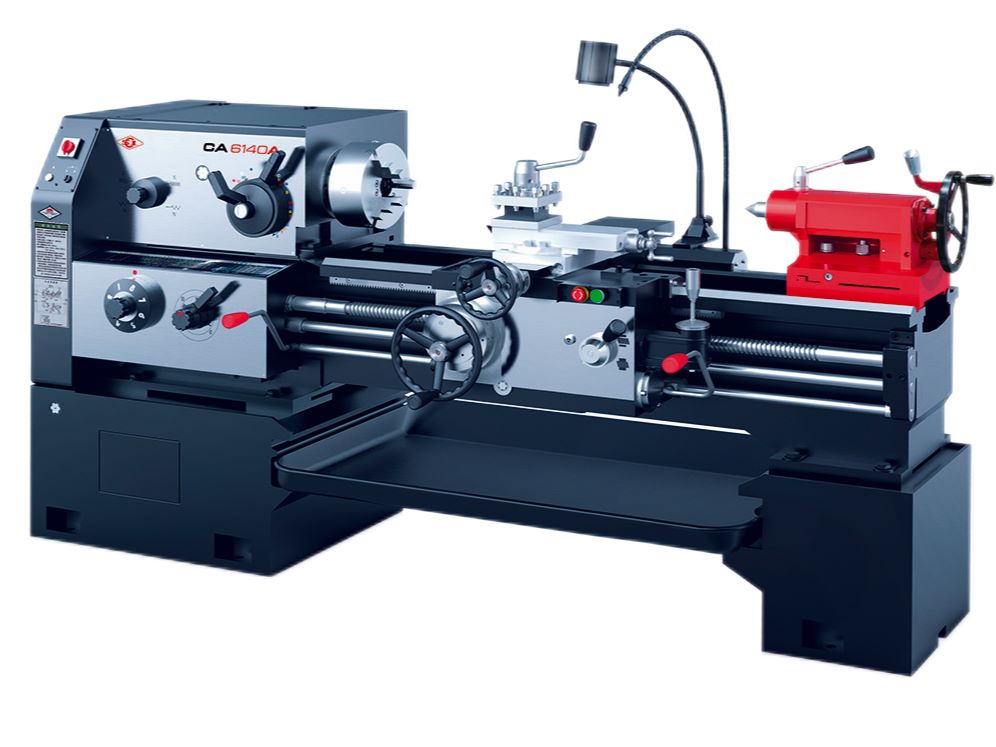

1. Novel appearance:

The appearance design of the machine tool integrates the concept of ergonomics into the mature machine tool structure to enhance the operating feel.

The main sheet metal parts adopt striking blue and gray stamping parts,and the overall effect is beautiful.

More accurate processing of various metric, English, modulus, diameter pitch threads. In addition, drilling,reaming, oil drawing and other work can also be easily completed.

Red Horizon: CA Series’s Striking Makeover (2012-2021)

Red Horizon: CA Series’s Striking Makeover (2012-2021)

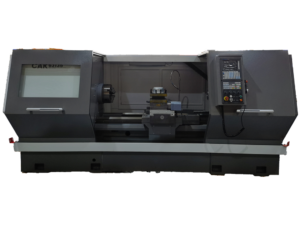

Into the Future: CA Series in Captivating Blue (2021-Present)

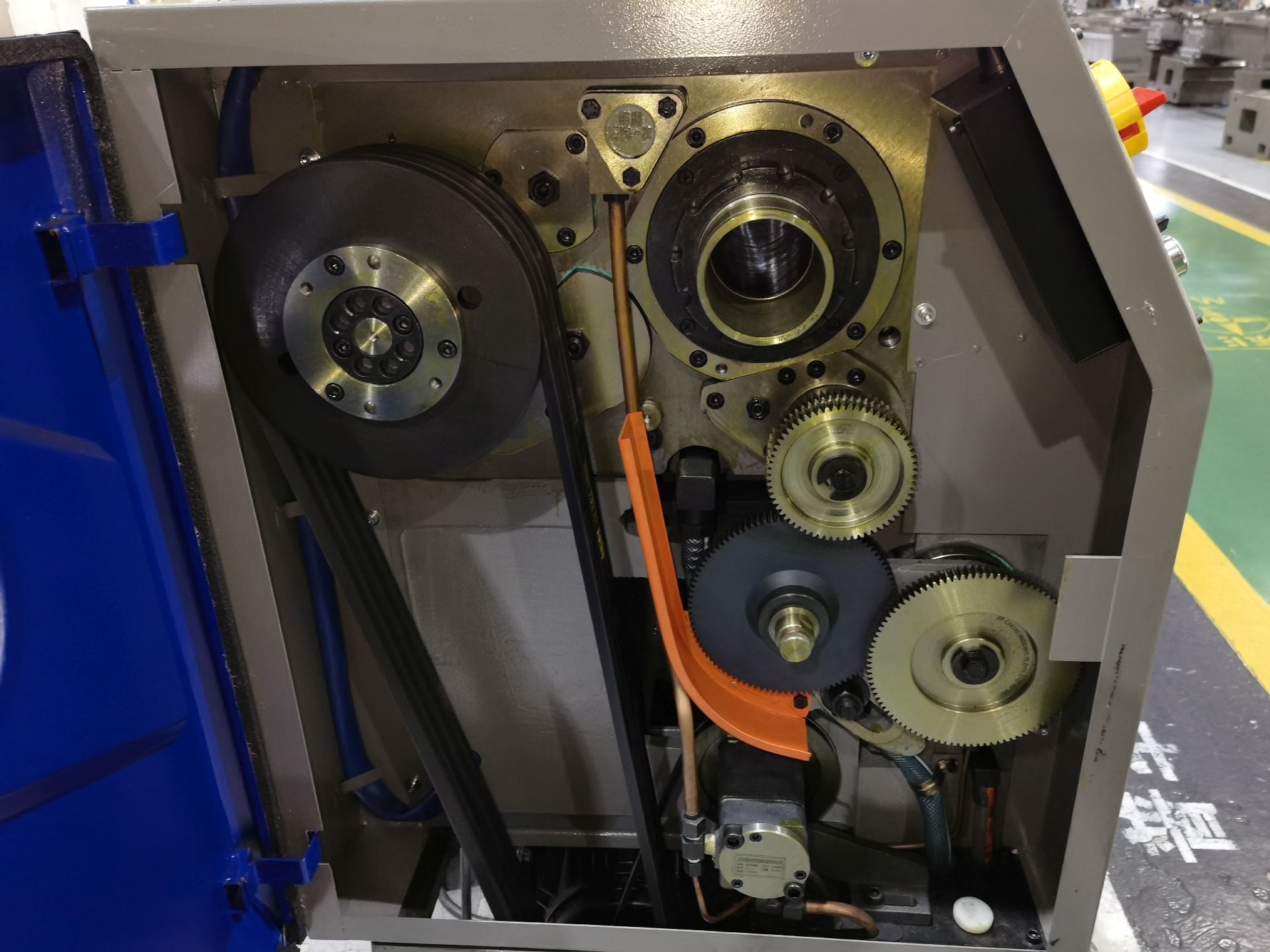

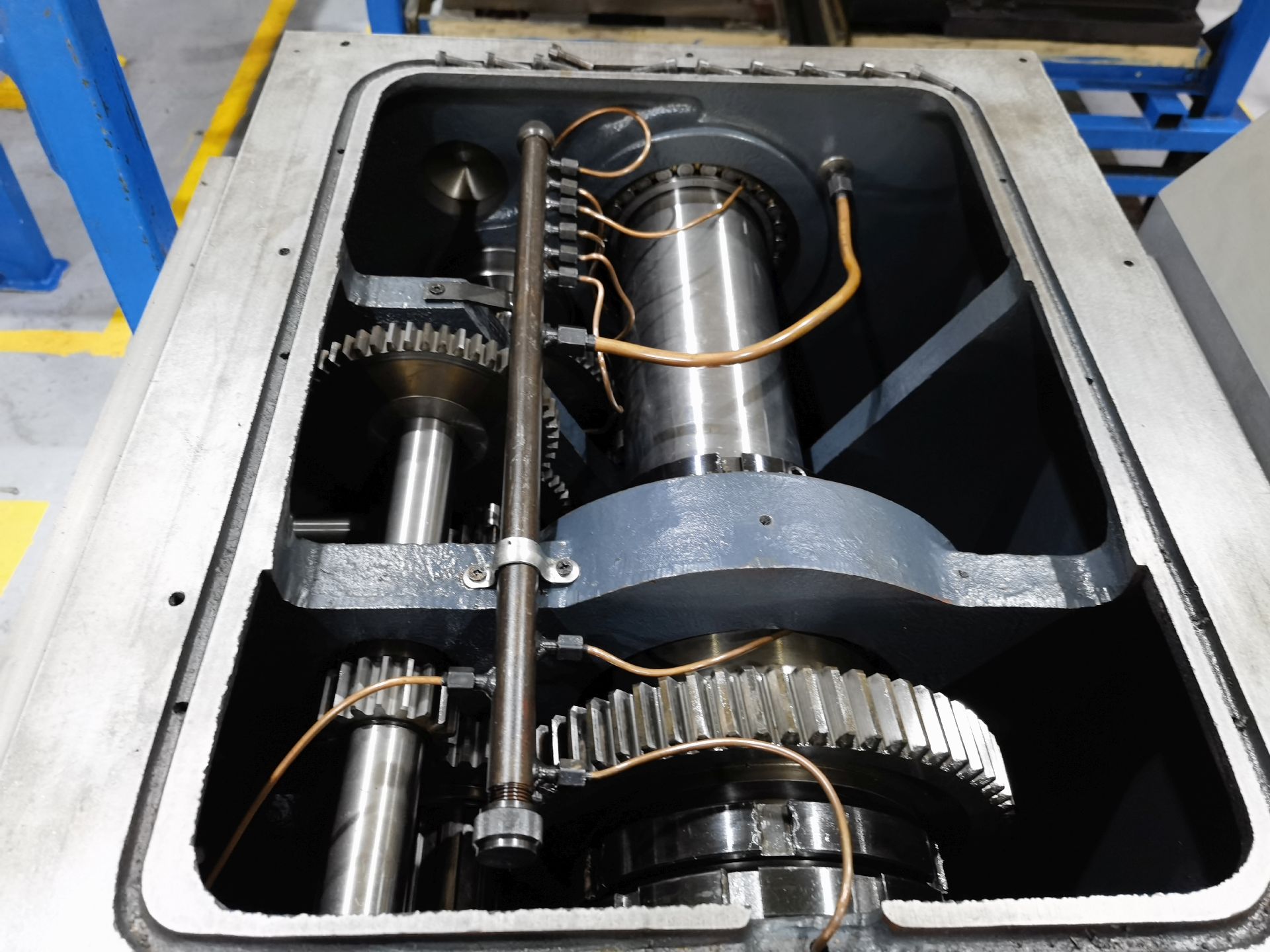

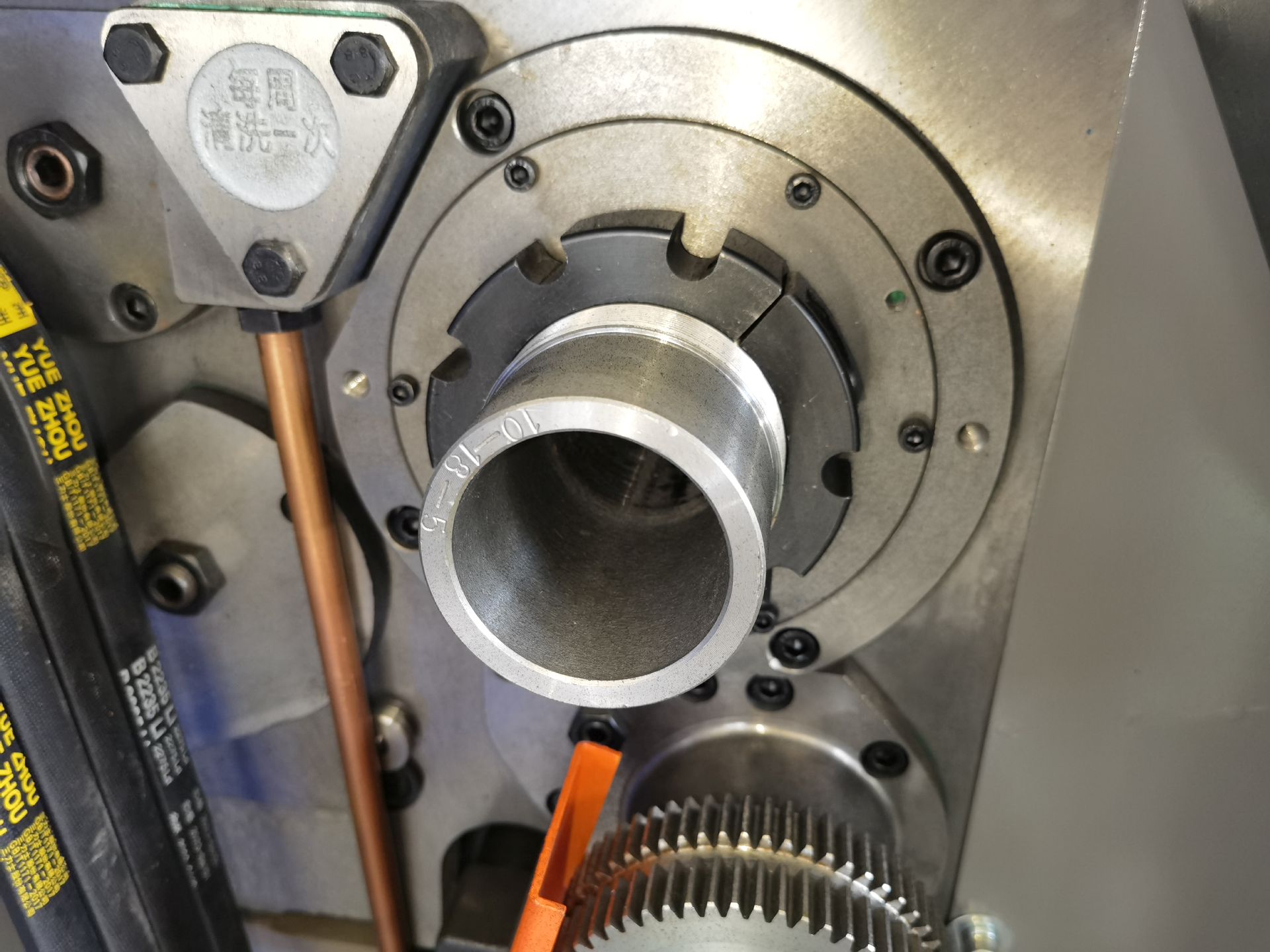

- Spindle Gearbox

- Spindle Control Panel

- Internal View of the Spindle Box

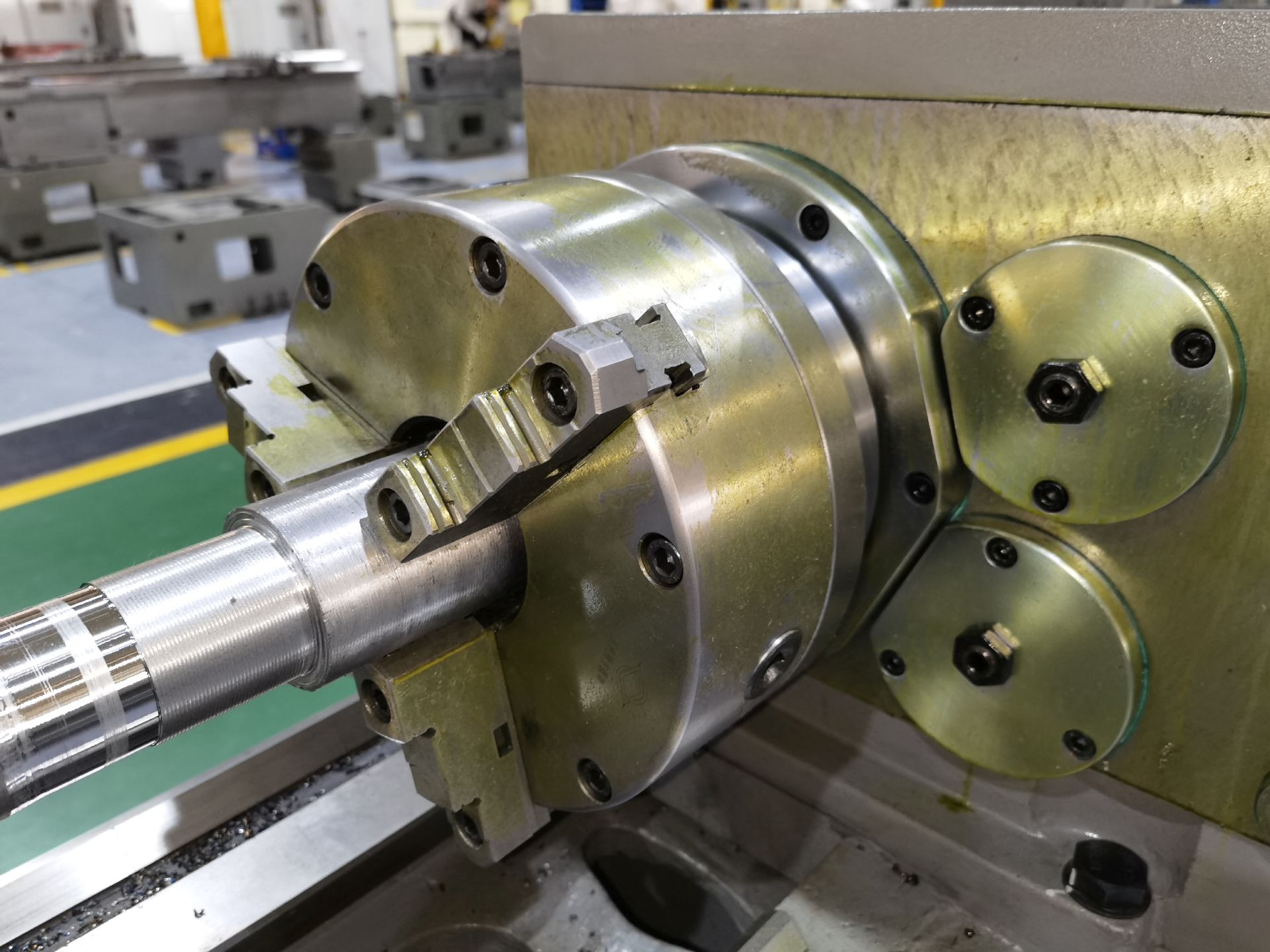

- Spindle

- Main Power Supply

- Spindle Control Lever

- Manual Chuck

- Manual Braking Mechanism

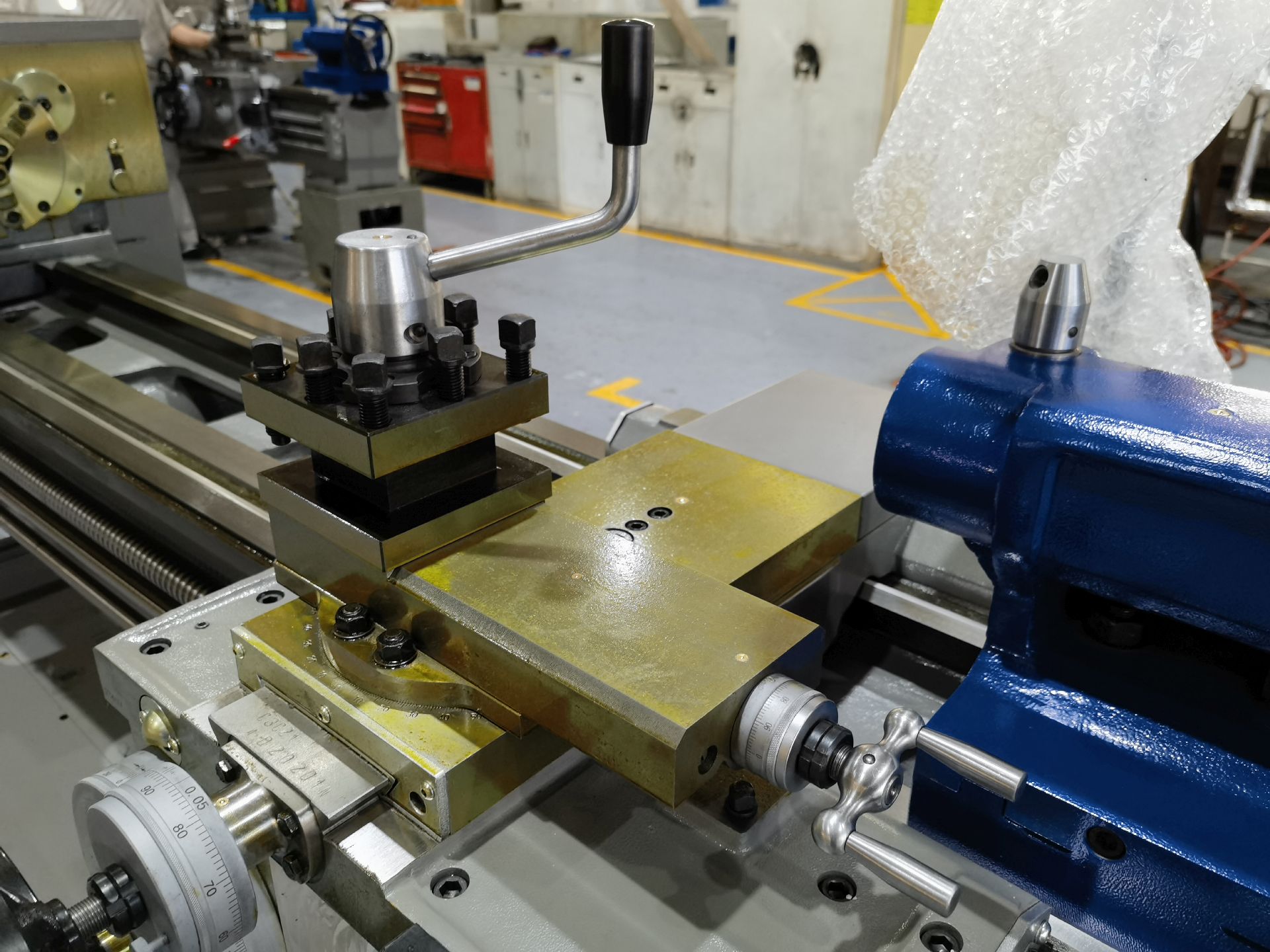

- Tool Post Structure

- Manual Tailstock

- Bed Guide Rail

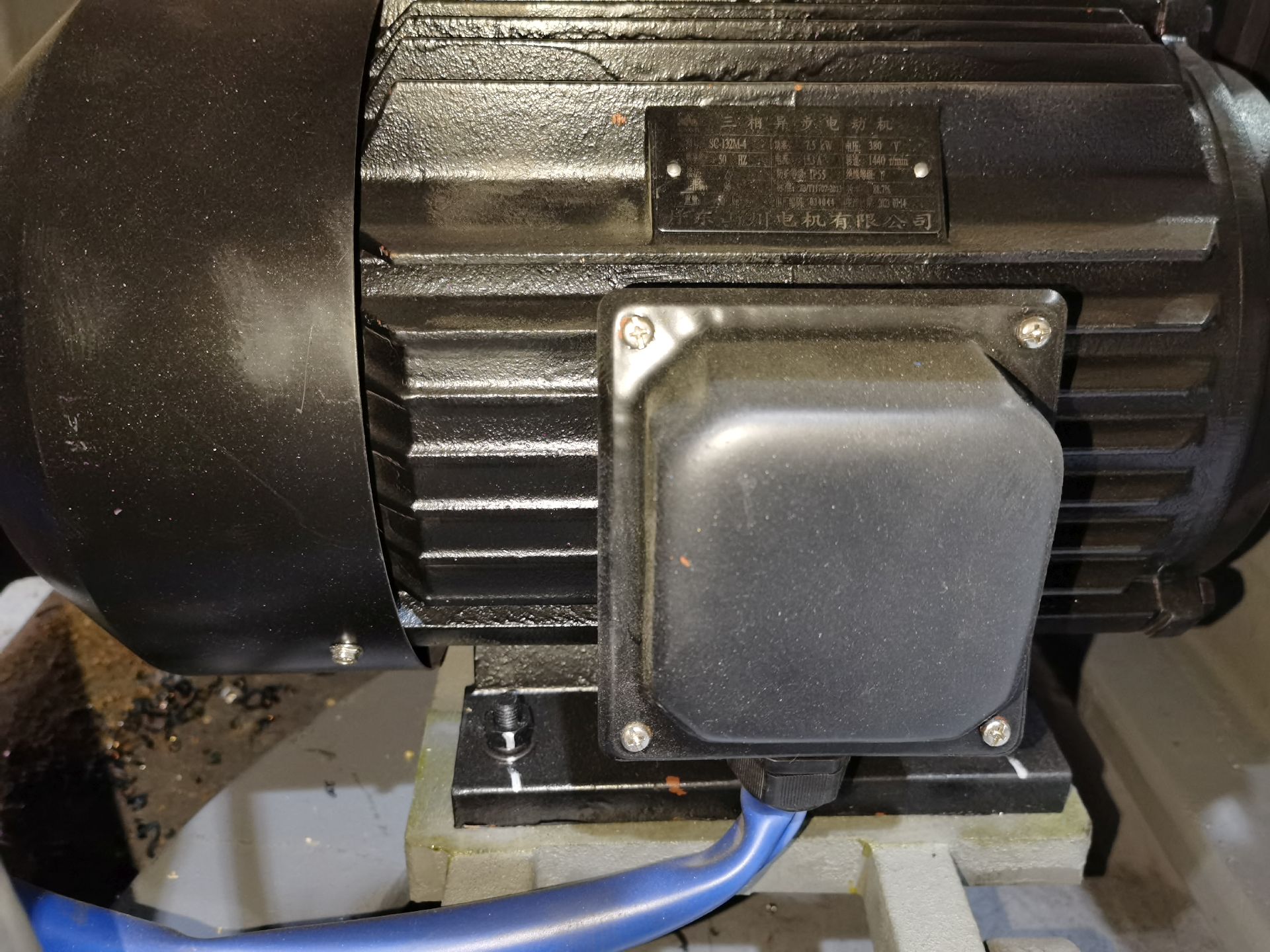

- Spindle Motor

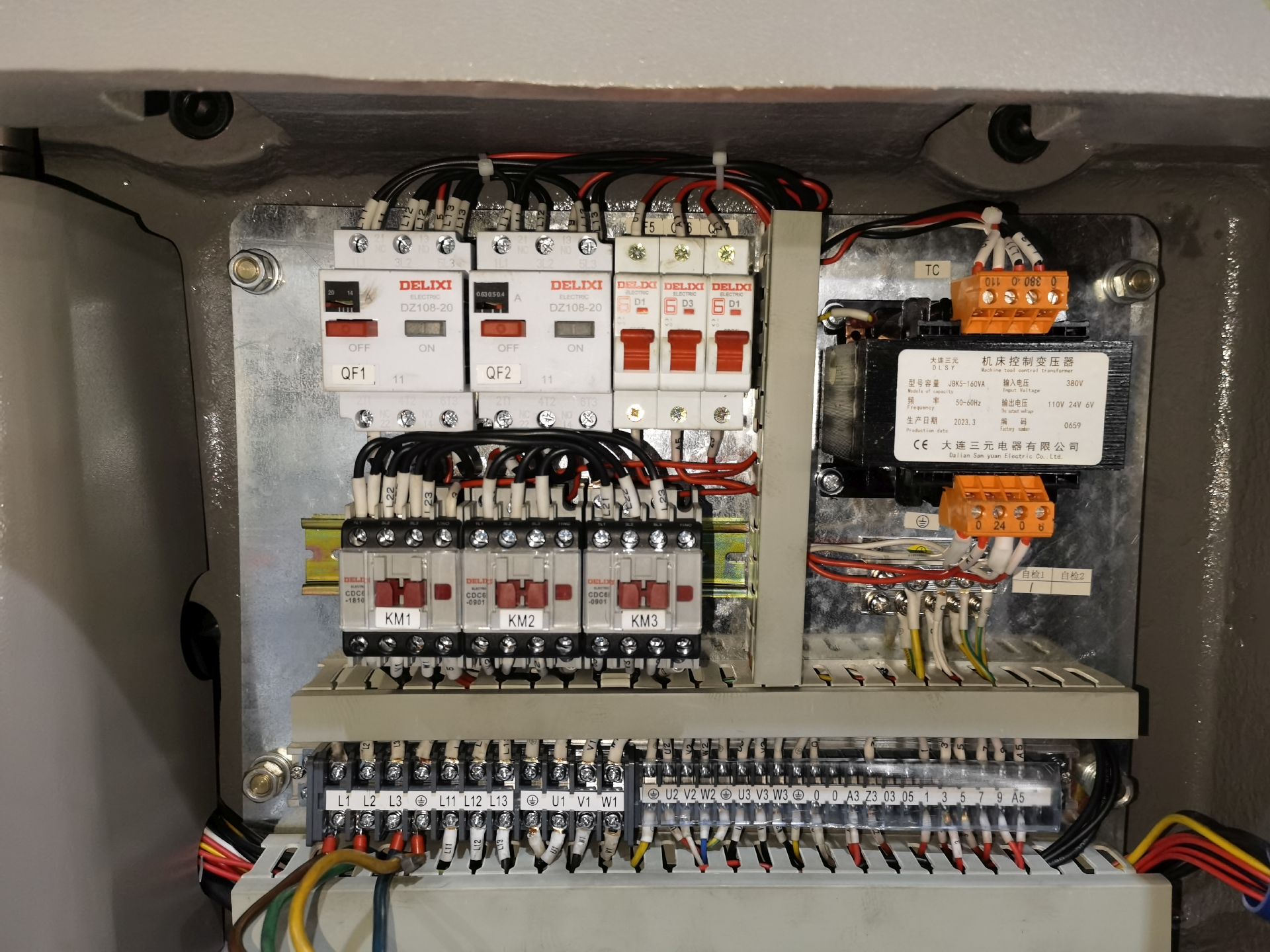

- Electrical Distribution Box

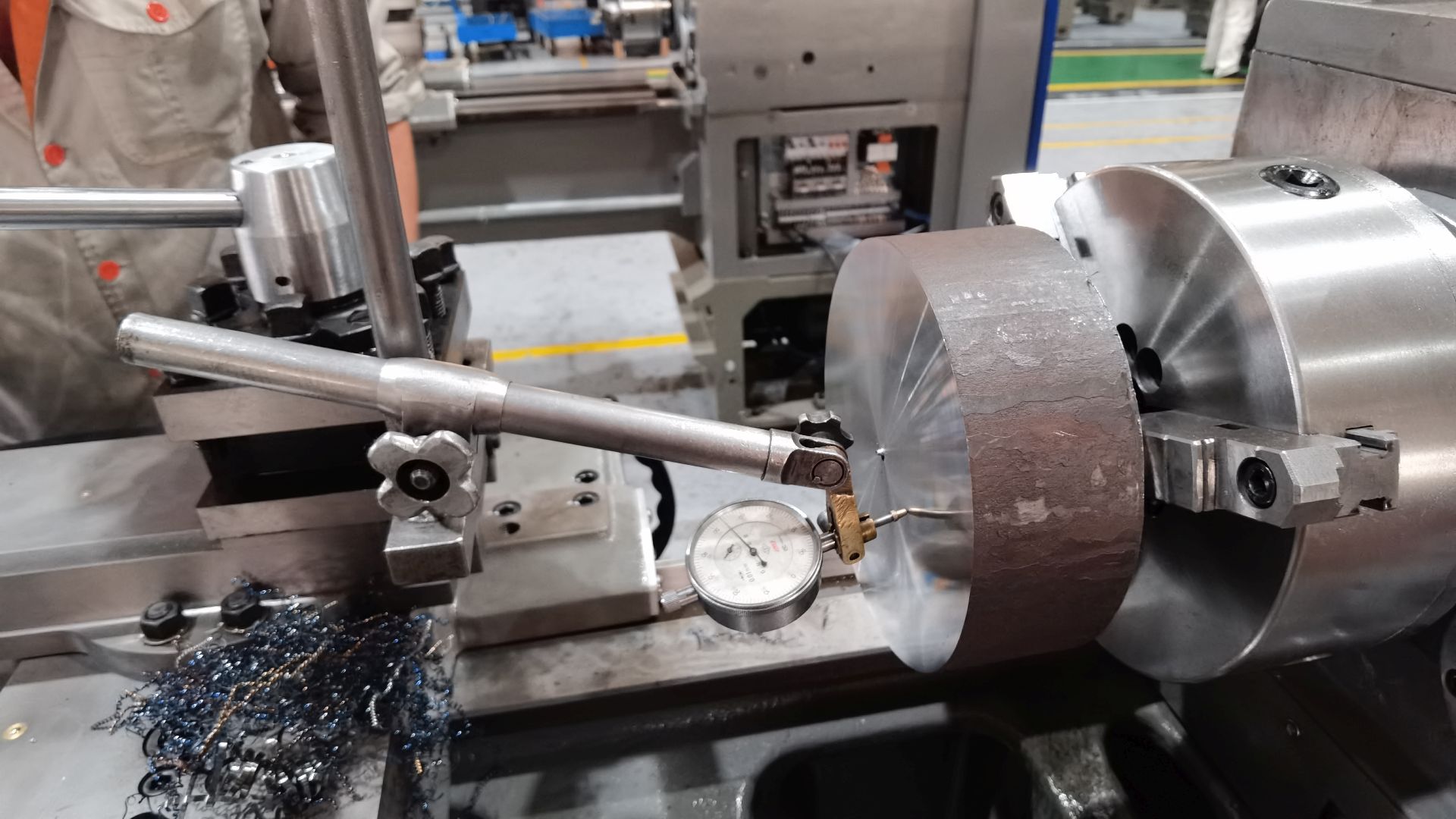

- IT7 Level Dimensional Accuracy

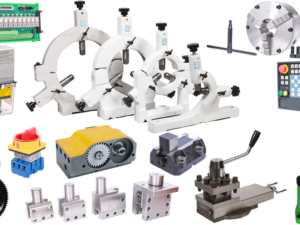

| Machine Configuration | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Quantity | Unit | CA6140A | CA6240A | CA6150A | CA6250A | ||||||

| Three-jaw chuck | Φ250K11250C/A16 | 1 Set | ◆ | ◆ | ◆ | ◆ | ||||||

| Φ250K11250C/A28 | 1 Set | |||||||||||

| Four-jaw chuck | Φ400K72400/A26 | 1 Set | ◇ | ◇ | ||||||||

| Φ400K72400/A28 | 1 Set | |||||||||||

| Face plate | Φ600 | 1 Set | ◇ | ◇ | ||||||||

| Centre Frame | Φ20-Φ125 | 1 Set | ◇ | ◇ | ◇ | ◇ | ||||||

| Φ100-Φ205 | 1 Set | |||||||||||

| Φ125-Φ250 | 1 Set | |||||||||||

| Follow the knife stands | Φ20-Φ80 | 1 Set | ◇ | ◇ | ◇ | ◇ | ||||||

| Top | 5 S25-2 | 1 Set | ◆ | ◆ | ◆ | ◆ | ||||||

| Centre sleeve | 6/5 S25-10 | 1 Set | ◆ | ◆ | ◆ | ◆ | ||||||

| 0011230L | 1 Set | |||||||||||

| Adjustable sizing block | – | 1 Set | ◇ | ◇ | ◇ | ◇ | ||||||

| Live center | – | 1 Set | ◇ | ◇ | ◇ | ◇ | ||||||

| Name | Quantity | Unit | CA6140B/A | CA6240B/A | CA6150B/A | CA6250B/A | ||||||

| Three-jaw chuck | Φ250K11250C/A16 | 1 Set | ◆ | ◆ | ◆ | |||||||

| Φ250K11250C/A28 | 1 Set | ◆ | ||||||||||

| Four-jaw chuck | Φ400K72400/A26 | 1 Set | ◇ | ◇ | ||||||||

| Φ400K72400/A28 | 1 Set | ◇ | ◇ | |||||||||

| Face plate | Φ600 | 1 Set | ◇ | ◇ | ||||||||

| Centre Frame | Φ20-Φ125 | 1 Set | ◇ | ◇ | ◇ | ◇ | ||||||

| Φ100-Φ205 | 1 Set | |||||||||||

| Φ125-Φ250 | 1 Set | |||||||||||

| Follow the knife stands | Φ20-Φ80 | 1 Set | ◇ | ◇ | ◇ | ◇ | ||||||

| Top | 5 S25-2 | 1 Set | ◆ | ◆ | ◆ | ◆ | ||||||

| Centre sleeve | 6/5 S25-10 | 1 Set | ◆ | ◆ | ◆ | |||||||

| 0011230L | 1 Set | ◆ | ◆ | ◆ | ◆ | |||||||

| Adjustable sizing block | – | 1 Set | ◇ | ◇ | ◇ | ◇ | ||||||

| Live center | – | 1 Set | ◇ | ◇ | ◇ | ◇ | ||||||

| Note:◆ Standard configuration ◇ Optional configuration: It means that there is no such configuration, if you need special configuration, please contact us | ||||||||||||