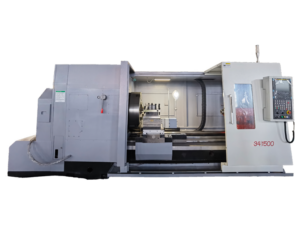

Home » Products » MACHINES » Conventional Machine Tool » Manual Lathe Machine » CW6163,CW6263,CW6180,CW6280,CW6194,CW6294,CW61100,CW61125,CW61140,CW61160

CW6163,CW6263,CW6180,CW6280,CW6194,CW6294,CW61100,CW61125,CW61140,CW61160

For the bed of this series, its double finning plate and inner finning plate on sidewall in width aredesigned for a composite structure between box type and diagonal bar, and thus the integralrigidity is increased by one third in comparison with that in single-wall and door shaped finningstructure; the slide carriage is equipped with a quick travel mechanism, which can be operatedvisually with a monolever; to transform the main shaft direction of rotation or to brake is underhydraulic control, and the function of hand brake or foot brake can be operated easily andflexibly on the safe side; both structural rigidity and driving rigidity of the lathes are higherwith steady precise and heavy cutting; the tailstock is equipped with a scale dial and scalemark and can be used visually; the lathes are of handsome appearance and easy cleaning andmaintenance on the whole; the headstock are forcedly lubricated with pressure oil; and thecooling fits are handsome on the safe side with hydroelectric separation.

Home » Products » MACHINES » Conventional Machine Tool » Manual Lathe Machine » CW6163,CW6263,CW6180,CW6280,CW6194,CW6294,CW61100,CW61125,CW61140,CW61160

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| Item | Unit | CW6163B | CW6263B | Unit | CW6180Q | CW6280Q | Unit | CW6194Q | CW6294Q | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max.swing over bed | mm | 630 | mm | 800 | mm | 940 | ||||||||||||||||||||||||||||||||

| Max.swing over gap | mm | 800 | mm | 970 | mm | 1110 | ||||||||||||||||||||||||||||||||

| Max.swing over tool-post | mm | 350 | mm | 520 | mm | 660 | ||||||||||||||||||||||||||||||||

| Max.length of workpiece | mm | 1000 | 1500 | 2000 | 3000 | 4000 | mm | 1000 | 1500 | 2000 | 3000 | 4000 | mm | 1000 | 1500 | 2000 | 3000 | 4000 | ||||||||||||||||||||

| Max.Turning length | Plain bed | mm | 850 | 1350 | 1850 | 2850 | 3850 | mm | 850 | 1350 | 1850 | 2850 | 3850 | mm | 850 | 1350 | 1850 | 2850 | 3850 | |||||||||||||||||||

| Gapped bed | mm | 550 | 1050 | 1550 | 2550 | 3550 | mm | 550 | 1050 | 1550 | 2550 | 3550 | mm | 550 | 1050 | 1550 | 2550 | 3550 | ||||||||||||||||||||

| Span of guide-way | mm | 550 | mm | 550 | mm | 550 | ||||||||||||||||||||||||||||||||

| Main spindle bore | mm | 104 | mm | 104 | mm | 104 | ||||||||||||||||||||||||||||||||

| Spindle taper hole | 1:20/120 | 1:20/120 | 1:20/120 | |||||||||||||||||||||||||||||||||||

| Taper of center | Morse NO.5 | Morse N0.5 | Morse NO.5 | |||||||||||||||||||||||||||||||||||

| Range of spindle speeds | r/min | 7.5~1000 | r/min | 6~800 | r/min | 6~800 | ||||||||||||||||||||||||||||||||

| Kinds of longitudinal&cross feeds | kinds | 64 each | kinds | 64 each | kinds | 64 each | ||||||||||||||||||||||||||||||||

| Rapid speed of carriage | mm/min | 4000 | mm/min | 4000 | mm/min | 4000 | ||||||||||||||||||||||||||||||||

| Max.travel of cross tool-post | mm | 390 | mm | 390 | mm | 390 | ||||||||||||||||||||||||||||||||

| Max.travel of upper tool-post | mm | 200 | mm | 200 | mm | 200 | ||||||||||||||||||||||||||||||||

| Dia.of tailstock quill | mm | Φ100 | mm | φ100 | mm | Φ100 | ||||||||||||||||||||||||||||||||

| Travel of tailstock quill | mm | 250 | mm | 250 | mm | 250 | ||||||||||||||||||||||||||||||||

| Taper of tailstock quill | Morse NO.5 | Morse NO.5 | Morse N0.5 | |||||||||||||||||||||||||||||||||||

| Main motor power | KW | 11 | KW | 11 | KW | 11 | ||||||||||||||||||||||||||||||||

| Rapid travel motor | KW | 1.1 | KW | 1.1 | KW | 1.1 | ||||||||||||||||||||||||||||||||

| Length of bed(mm) | dimension(L×W×H)mm | Machine weight(Kg) | Overall dimension(L×W×H)mm | Machine weight(Kg) | Overall dimension(L×W×H)mm | Machine weight(Kg) | ||||||||||||||||||||||||||||||||

| 1000 | 3160×1385×1575 | 3600 | 3160×1385×1660 | 3800 | 3160×1385×1735 | 4000 | ||||||||||||||||||||||||||||||||

| 1500 | 3525×1385×1575 | 3700 | 3525×1385×1660 | 3900 | 3525×1385×1735 | 4100 | ||||||||||||||||||||||||||||||||

| 2000 | 4160×1385×1575 | 4100 | 4160×1385×1660 | 4300 | 4160×1385×1735 | 4500 | ||||||||||||||||||||||||||||||||

| 3000 | 5155×1385×1575 | 4700 | 5155×1385×1660 | 4900 | 5155×1385×1735 | 5100 | ||||||||||||||||||||||||||||||||

| 4000 | 6155×1455×1575 | 5800 | 6155×1455×1660 | 6300 | 6155×1455×1735 | 6800 | ||||||||||||||||||||||||||||||||

| The Machine Tool Senes CW6180B/CW6180D | Big Bore/General Heightening Lathe of CW61100D/CW61100Q | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Item | Unit | CW6180B | CW6180D | Unit | CW61100D | CW61100Q | ||||||||||

| Max.swing over bed | mm | 800 | mm | 1000 | ||||||||||||

| Max,Swing over tool-post | mm | 480 | mm | 800 | ||||||||||||

| Max.length of workpiece | mm | 1500/2000/3000/4000/5000/6000/8000/10000 | mm | 1500/2000/3000/4000/5000/6000/8000/10000 | ||||||||||||

| Max.Turning length | mm | 1350/1850/2850/3850/4850/5850/7850/9850 | mm | 1350/1850/2850/3850/4850/5850/7850/9850 | ||||||||||||

| Span of guide-way | mm | 600 | mm | 600 | ||||||||||||

| Spindle taper hole | 1:20/120 | 1:20/150 | 1:20/150 | 1:20/120 | ||||||||||||

| Main spindle bore | mm | 104 | 140 | mm | 140 | 104 | ||||||||||

| Spindle hose | C11/A₂11 | C11/A₂11 | ||||||||||||||

| Ranges of spindle speeds | r/min | 5.4~720 | r/min | 5.4~720 | ||||||||||||

| NO.of spindle speeds | 18 | 18 | ||||||||||||||

| No.of longitudinal l&cross feeds | 64 each | 64 each | ||||||||||||||

| 1:1 Range of longitudinal feed | mm/r | 0.1~1.52 | mm/r | 0.1~1.52 | ||||||||||||

| 16:1 Range of longitudinal feed | mm/r | 1.6~24.3 | mm/r | 1.6~24.3 | ||||||||||||

| Cross-to-longitudinal feed rate | 1/2 | 1/2 | ||||||||||||||

| Pitch of lead screw | mm | 12 | mm | 12 | ||||||||||||

| No.of metric thread | kinds | 50 | kinds | 50 | ||||||||||||

| Range of metric thread | mm | 1-240 | mm | 1-240 | ||||||||||||

| No.of inch thread | kinds | 26 | kinds | 26 | ||||||||||||

| Range of inch thread | t.p.i | 14-1 | t.p.i | 14-1 | ||||||||||||

| No.of inch thread | kinds | 53 | kinds | 53 | ||||||||||||

| Range of inch thread | mm | 0.5~120 | mm | 0.5~120 | ||||||||||||

| No.of diametral pitch thread | kinds | 24 | kinds | 24 | ||||||||||||

| Range of diametral pitch thread | t.p.i | 28-1 | t.p.i | 28-1 | ||||||||||||

| Rapid speed of carriage | mm/min | 4000 | <br /> mm/min | 4000 | ||||||||||||

| Max.travel of cross tool-post | mm | 450 | mm | 550 | ||||||||||||

| Max.travel of upper tool-post | mm | 200 | mm | 200 | ||||||||||||

| Section of tool shank | mm | 32×32 | mm | 32×32 | ||||||||||||

| Dia.of tailstock quill | <br /> mm | 3m≤Φ100/4m≥Φ125 | <br /> mm | Φ125 | ||||||||||||

| Travel of tailstock quill | <br /> mm | 250 | <br /> mm | 250 | ||||||||||||

| Taper of tailstock quill | Morse NO.6 | Morse NO.6 | ||||||||||||||

| Main motor power | KW | 11 | KW | 11 | ||||||||||||

| Rapid travel motor | KW | 1.1 | KW | 1.1 | ||||||||||||

| Model | Length of bed(mm) | Overall dimension(L×W×H)mm | Machine weight(Kg) | Length of bed(mm) | Overall dimension(L×W×H)mm | Machine weight(Kg) | ||||||||||

| 1500 | 3600×1525×1500 | 4900 | 1500 | 3600×1625×1600 | 5500 | |||||||||||

| 2000 | 4165×1525×1500 | 5100 | 2000 | 4165×1625×1600 | 5900 | |||||||||||

| 3000 | 5290×1525×1500 | 5500 | 3000 | 5290×1625×1600 | 6100 | |||||||||||

| 4000 | 6415×1525×1500 | 6200 | 4000 | 6415×1625×1600 | 6800 | |||||||||||

| 5000 | 7510×1525×1500 | 6900 | 5000 | 7510×1625×1600 | 7500 | |||||||||||

| 6000 | 8635×1525×1500 | 7600 | 6000 | 8635×1625×1600 | 8200 | |||||||||||

| 8000 | 10500×1525×1500 | 9000 | 8000 | 10500×1625×1600 | 9600 | |||||||||||

| 10000 | 12365×1525×1500 | 10400 | 10000 | 12365×1625×1600 | 11000 | |||||||||||

| Net weight | Kg | 3000 | Kg | 3000 | ||||||||||||

| The Machine Tool Senes CW61100B/CW61125B | General Heightening Lathe of CW61140B/CW61160B | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Item | Unit | CW61100B | CW61125B | Unit | CW61140B | CW61160B | ||||||||||||||||||||

| Max.swing over bed | mm | 1000 | 1250 | mm | 1400 | 1600 | ||||||||||||||||||||

| Max.swing over tool-post | mm | 615 | 865 | mm | 960 | 1200 | ||||||||||||||||||||

| Max.length of workpiece | mm | 1500 | 3000 | 5000 | 6000 | 8000 | mm | 1500 | 3000 | 5000 | 6000 | 8000 | ||||||||||||||

| Max.Turning length | mm | 1300 | 2800 | 4800 | 5800 | 7800 | mm | 1300 | 2800 | 4800 | 5800 | 7800 | ||||||||||||||

| Span of guide-way | mm | 755 | mm | 755 | ||||||||||||||||||||||

| Spindle taper hole | 1:20 Metric No.140# | 1:20 Metric No.140# | ||||||||||||||||||||||||

| Main spindle bore | mm | 130 | mm | 130 | ||||||||||||||||||||||

| Ranges of spindle speeds | n(1)Forward | r/min | 3.15~315 | r/min | 3.15~315 | |||||||||||||||||||||

| Reverse | 3.5~278 | 3.5~278 | ||||||||||||||||||||||||

| n(2)Forward | 2~200 | 2~200 | ||||||||||||||||||||||||

| Reverse | 2.24~178 | 2.24~178 | ||||||||||||||||||||||||

| No.of forward turning speeds | 21 | 21 | ||||||||||||||||||||||||

| No.of reverse turning speeds | 12 | 12 | ||||||||||||||||||||||||

| No.of feeds per revolution(longitudinal/transverse) | 56 | 56 | ||||||||||||||||||||||||

| Max.travel of cross tool-post | mm | 630 | mm | 630 | ||||||||||||||||||||||

| Max.travel of upper tool-post | mm | 300 | mm | 325 | ||||||||||||||||||||||

| Section of tool shank | mm | 45×45 | mm | 45×45 | ||||||||||||||||||||||

| Dia.of tailstock quill | mm | 160 | mm | 160 | ||||||||||||||||||||||

| Max.travel of tailstock quill | mm | 300 | mm | 300 | ||||||||||||||||||||||

| Taper hole of tailstock quill | Morse NO.6 | Morse NO.6 | ||||||||||||||||||||||||

| Main motor power | KW | 22 | KW | 22 | ||||||||||||||||||||||

| Rapid travel motor | KW | 1.5 | KW | 1.5 | ||||||||||||||||||||||

| Max.weight between two centers | Kg | 6000 | Kg | 6000 | ||||||||||||||||||||||

| Model | mm | 1500 | 3000 | 5000 | 6000 | 8000 | mm | 1500 | 3000 | 5000 | 6000 | 8000 | ||||||||||||||

| Length | mm | 4600 | 6100 | 8100 | 9100 | 11100 | mm | 4600 | 6100 | 8100 | 9100 | 11100 | ||||||||||||||

| Width | mm | 2150 | 2275 | mm | 2350 | 2450 | ||||||||||||||||||||

| Height | mm | 1700 | 1825 | mm | 1900 | 2000 | ||||||||||||||||||||

| Machine weight | Kg | 9200/10200 | 10700/11900 | 13000/14500 | 13700/15400 | 15700/17900 | Kg | 11000/11900 | 12800/13900 | 15600/16900 | 16600/18000 | 19200/20800 | ||||||||||||||

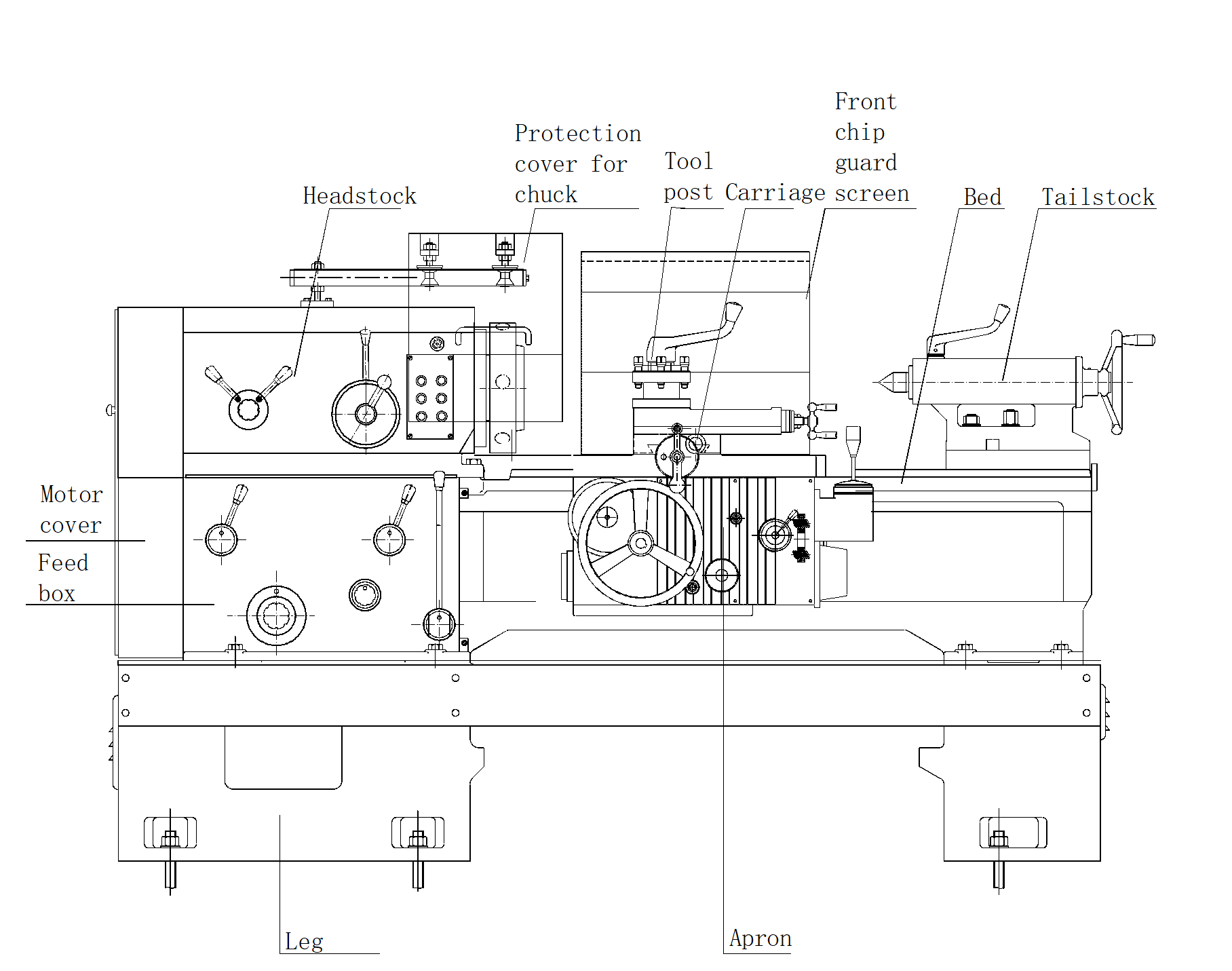

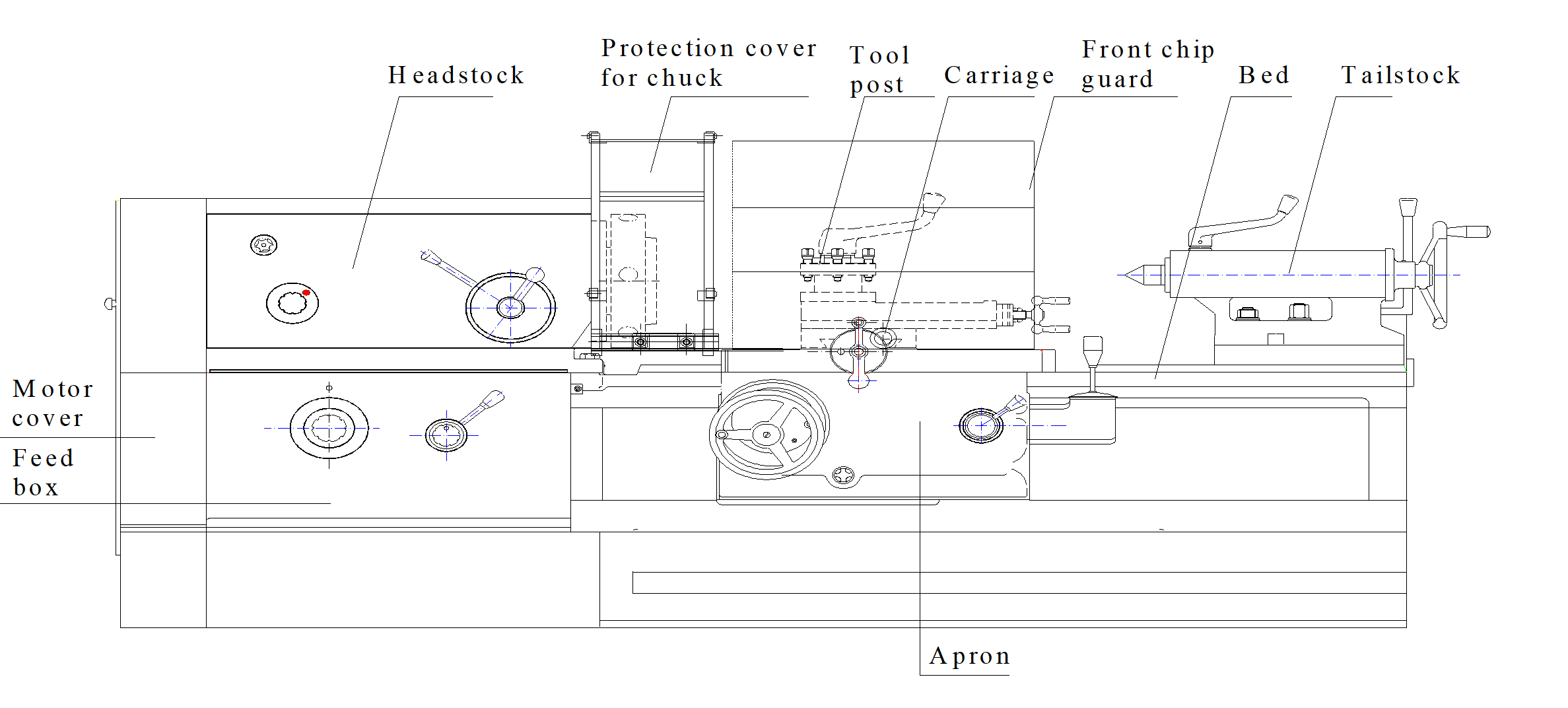

CW63 Layout of the Machine

CW80 Layout of the Machine

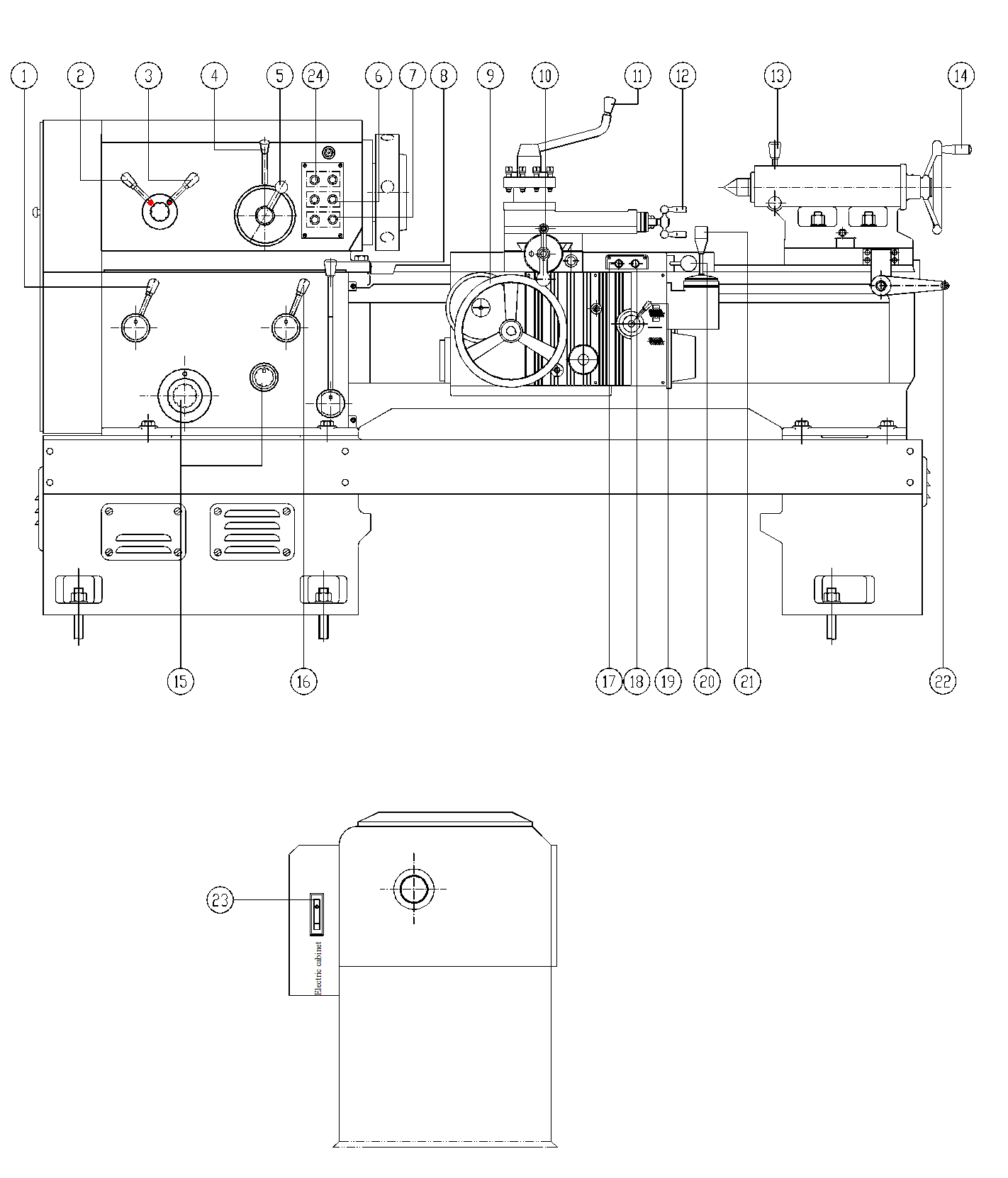

Control Levers of the Machine

| No. in Fig | Name and Use |

|---|---|

| 1 | Changing levers for changing speed of threads of Metric and Inch system |

| 2、3 | Changing lever for coarse pitch and L.&R. thread cutting |

| 4、5 | Changing lever for rapid speed/low speed of spindle |

| 6 | Start/Stop buttons for cooling system |

| 7 | Start push button for main drive motor and emergency stop button |

| 8、20 | Start/Stop buttons of spindle |

| 9 | Handwheel for longitudinal travel of carriage |

| 10 | Handle for traversing of cross slide |

| 11 | Indexing and fixing lever of square tool post |

| 12 | Handle for traveling of compound rest slide |

| 13 | Lever for fixing tailstock center sleeve |

| 14 | Lever for traveling of tailstock quill |

| 15 | Adjusting Handwheel for adjusting pitch and feed |

| 16 | Changing lever for leadscrew and feed rod |

| 17 | Emergency stop button |

| 18 | Start button of spindle |

| 19 | Control lever for split nut |

| 21 | Joystick lever with a push button for power longitudinal or cross feed and four-way traverse |

| 22 | Lever for tailstock movement |

| 23 | General Switch for power supply |

| 24 | Button for illuminating light and buzzer |

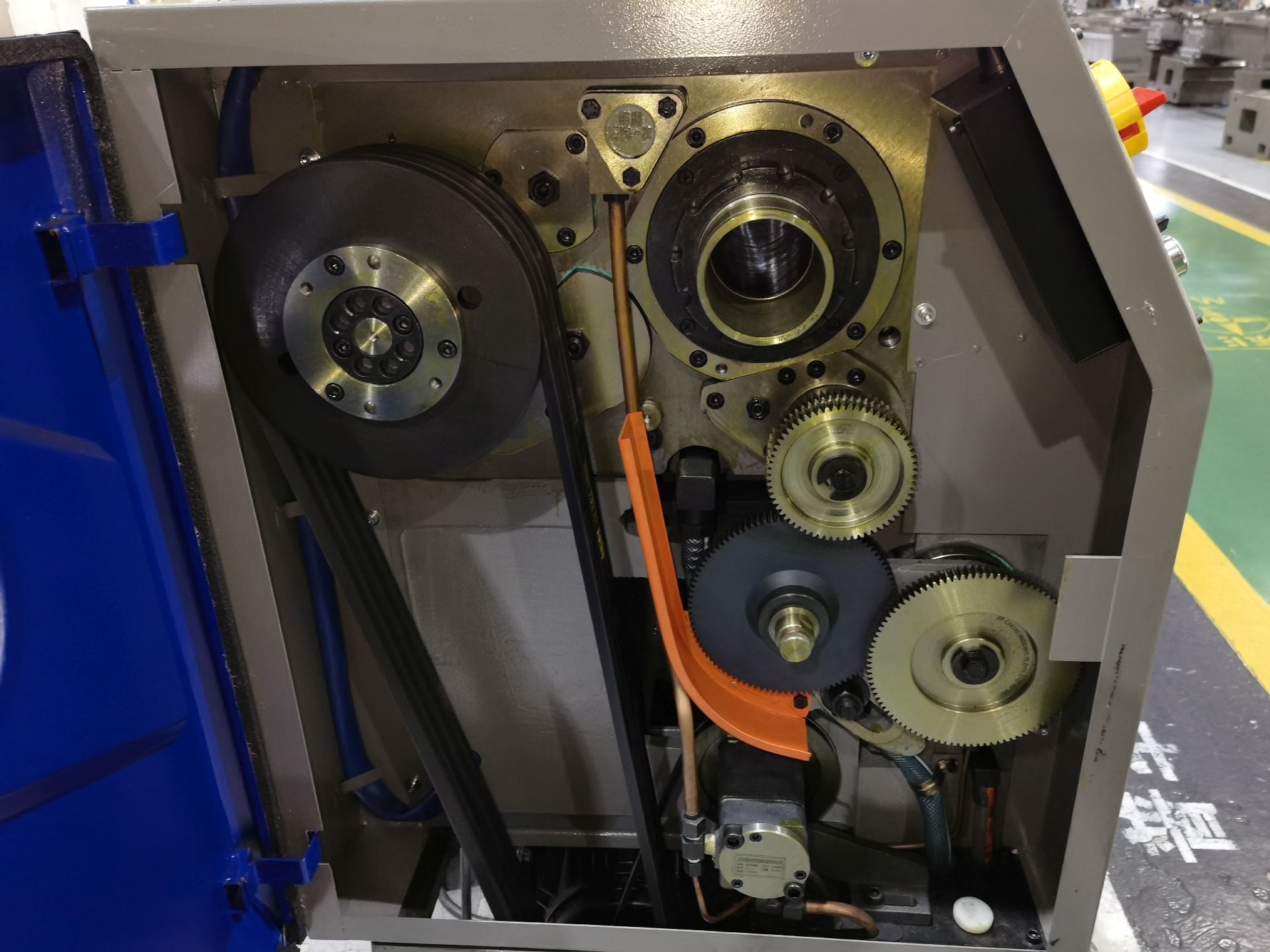

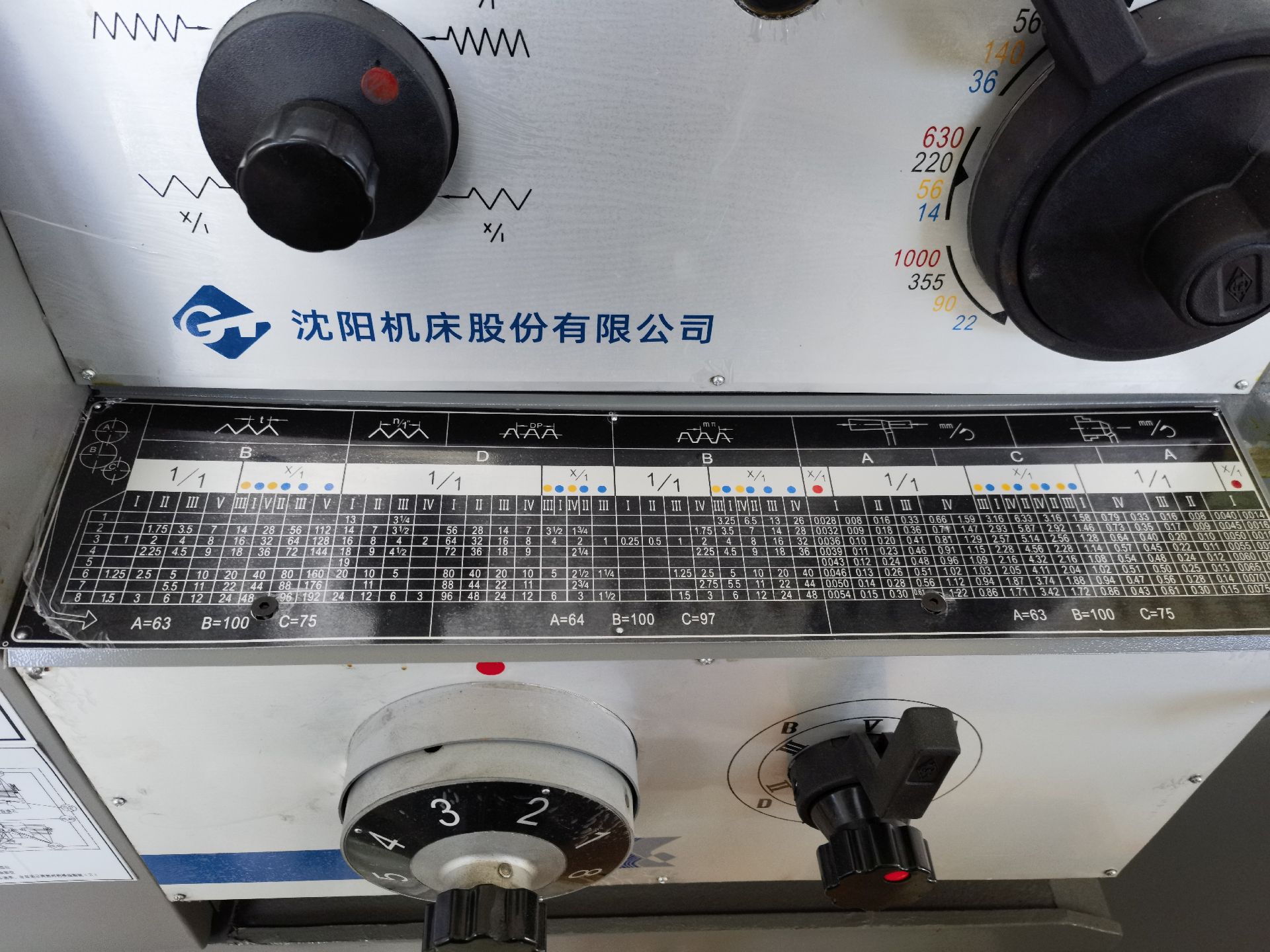

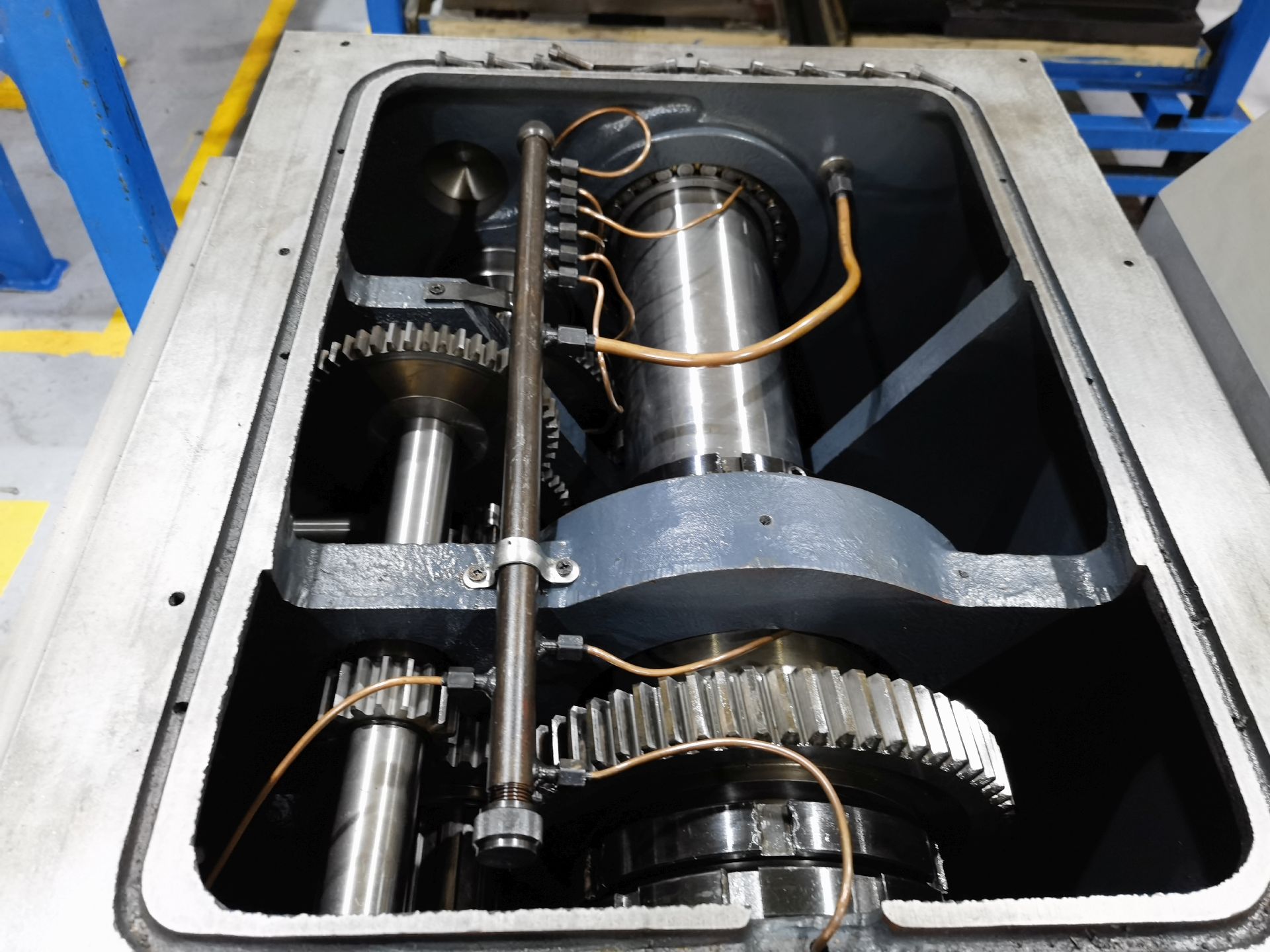

- Spindle Gearbox

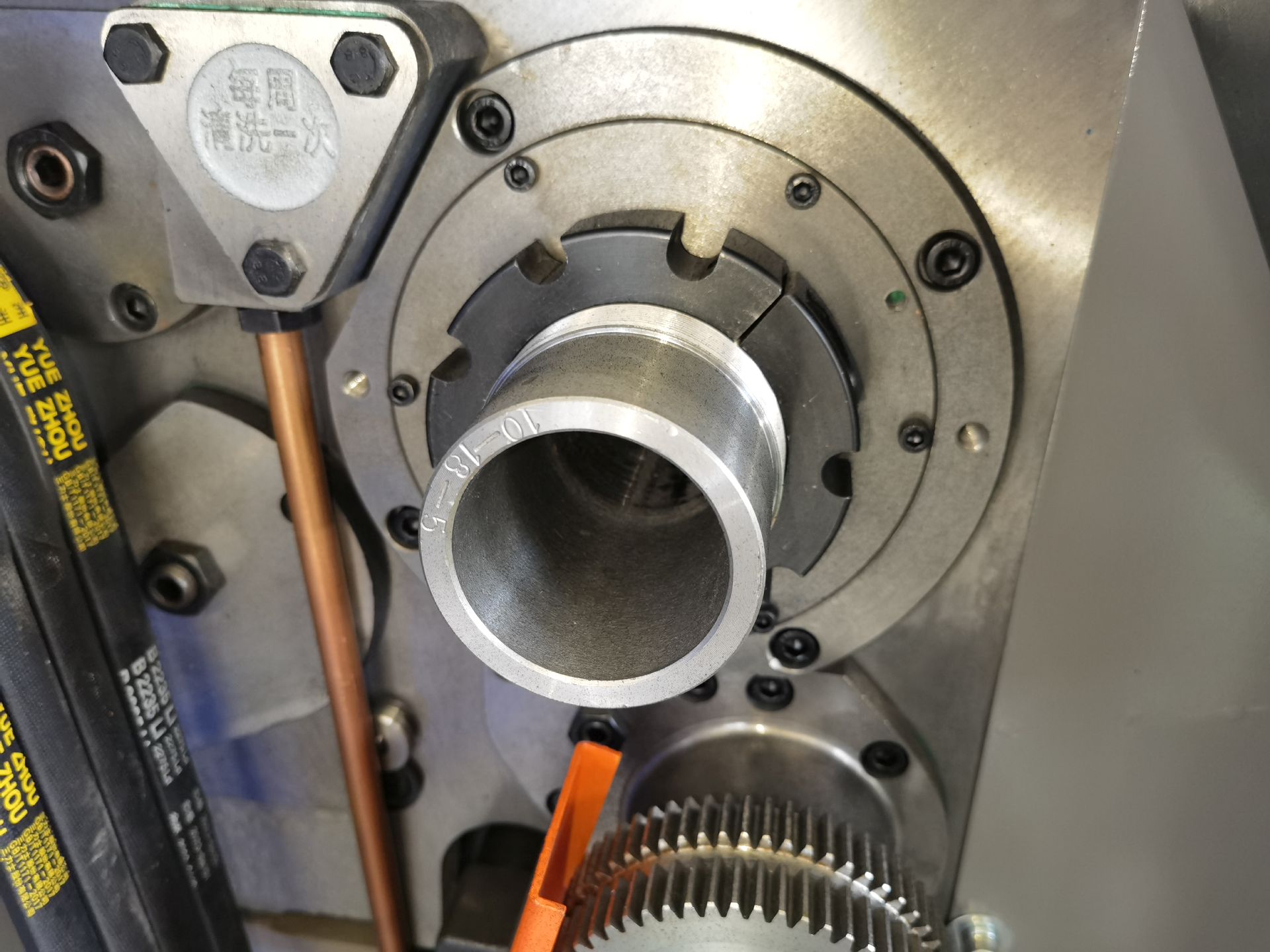

- Spindle Control Panel

- Internal View of the Spindle Box

- Spindle

- Main Power Supply

- Spindle Control Lever

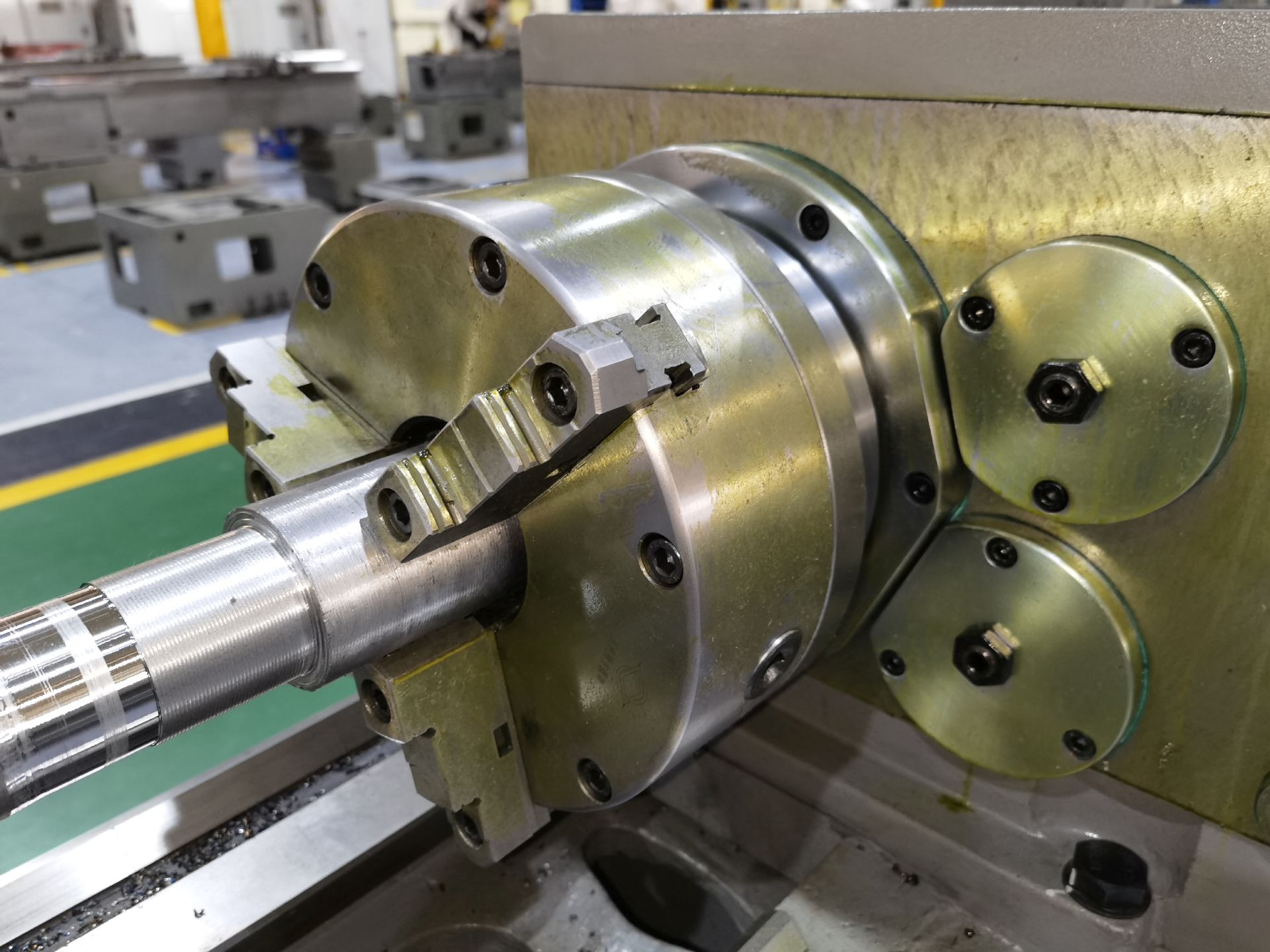

- Manual Chuck

- Manual Braking Mechanism

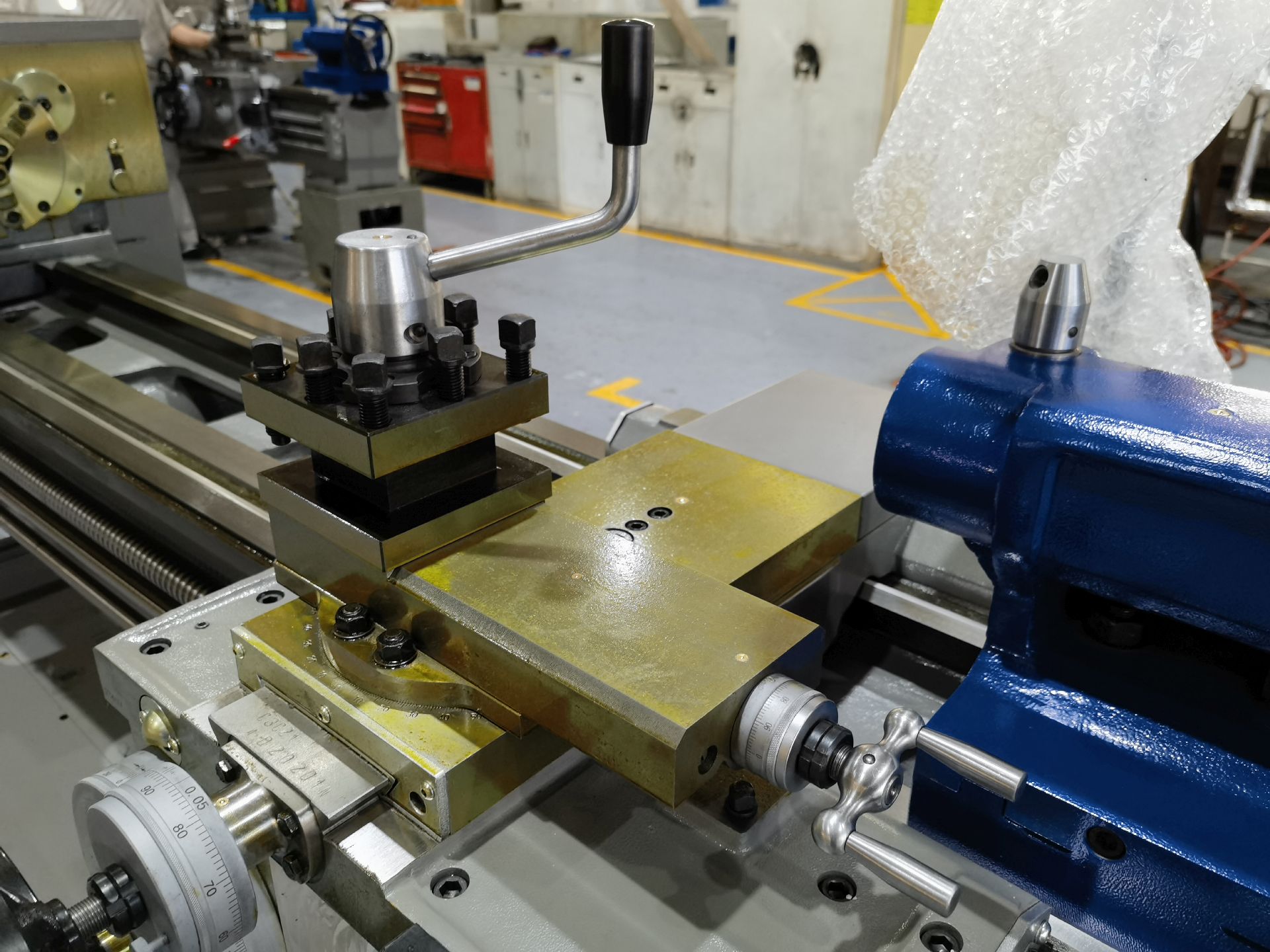

- Tool Post Structure

- Manual Tailstock

- Bed Guide Rail

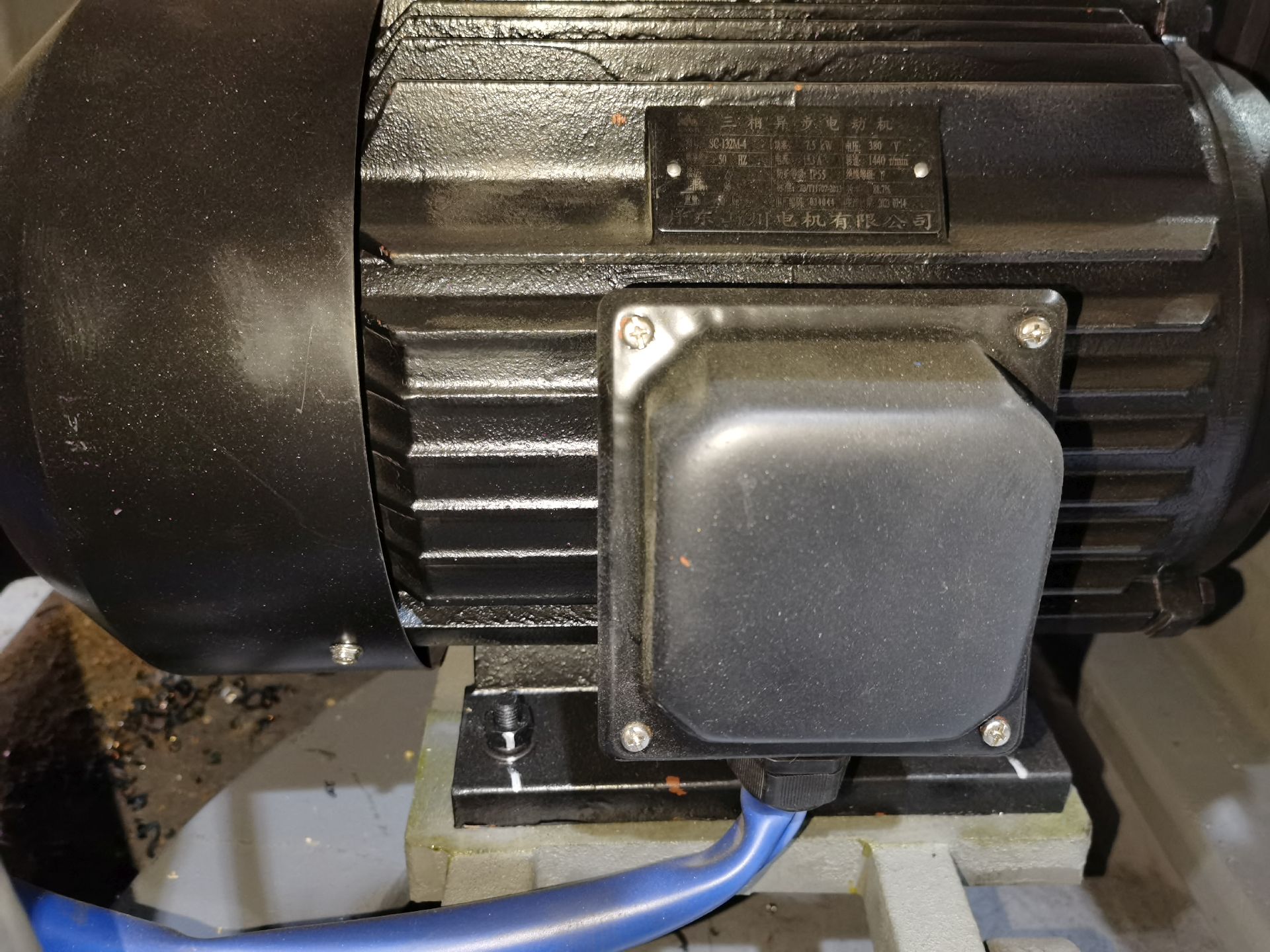

- Spindle Motor

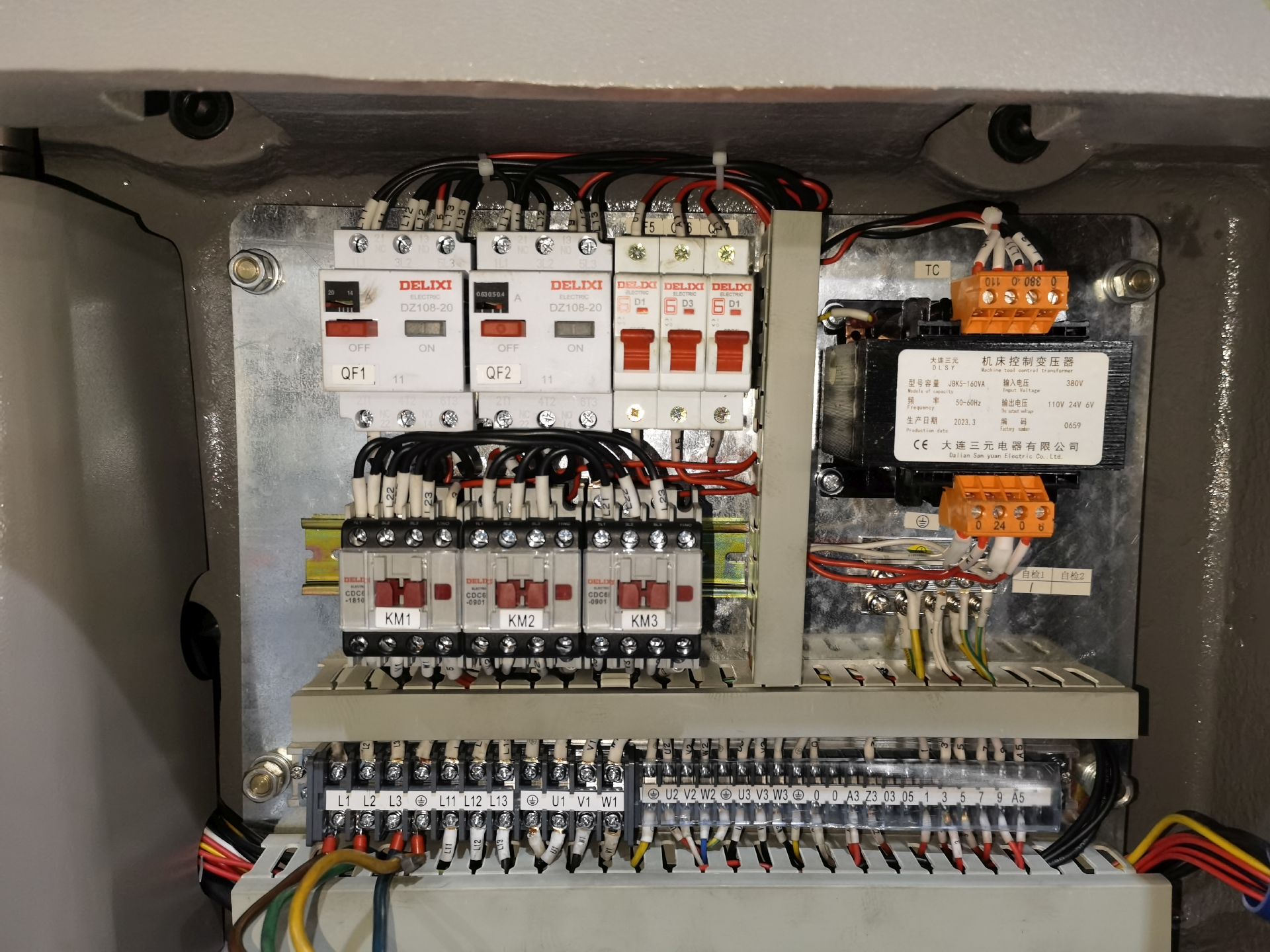

- Electrical Distribution Box

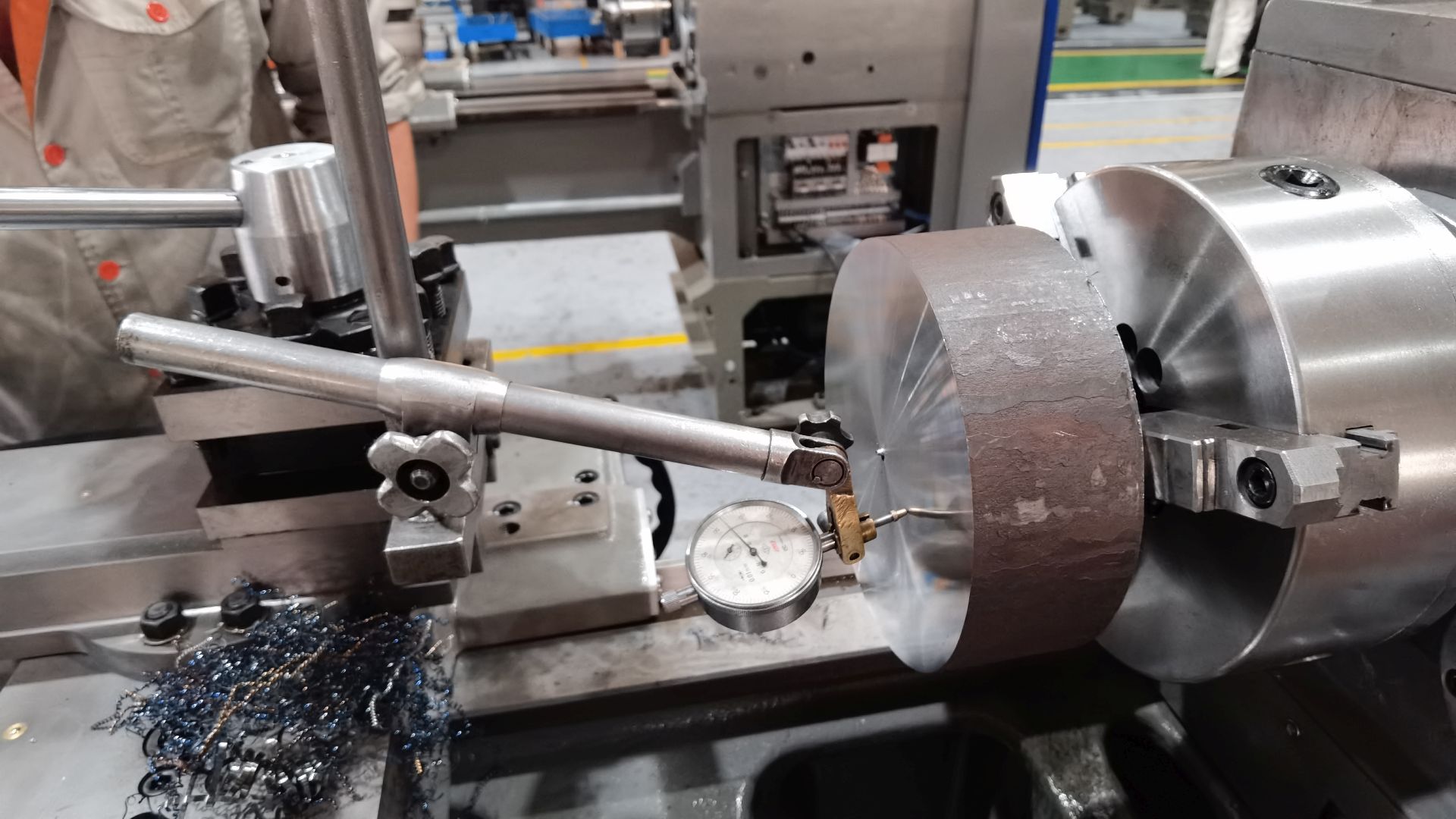

- IT7 Level Dimensional Accuracy

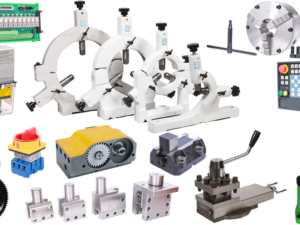

| Standard Accessories/Optional Accessories | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Specification | CW6163B | CW6263B | CW6180B | CW6280B | CW6193B | CW61110B | |||||||

| 3-Jaw chuck | Φ315 | ● | ● | ● | ● | ● | ● | |||||||

| Follow rest | Φ20-130 | ● | ● | |||||||||||

| Φ30-130 | ● | ● | ||||||||||||

| Φ30-180 | ● | ● | ||||||||||||

| Φ50-220 | ★ | ★ | ||||||||||||

| Φ200-310 | ★ | ★ | ||||||||||||

| Steady rest | Φ20-170 | ● | ● | ★ | ★ | |||||||||

| Φ40-350 | ● | ● | ||||||||||||

| Φ30-420 | ● | |||||||||||||

| Φ40-460 | ● | |||||||||||||

| <br /> Face plate | Φ650 | ● | ★ | |||||||||||

| Φ800 | ★ | ● | ★ | ★ | ||||||||||

| Φ930 | ● | ★ | ||||||||||||

| Φ1120 | ● | |||||||||||||

| Φ1600 | ||||||||||||||

| Center and Center sleeve | Metric120;Morse5 | ● | ● | ● | ● | ● | ● | |||||||

| Metric120;Morse6 | ||||||||||||||

| Live center | Morse6 | |||||||||||||

| Metric80;Morse6 | ||||||||||||||

| Cooling device and illuminating equipment | ● | ● | ● | ● | ● | ● | ||||||||

| Tools | ● | ● | ● | ● | ● | ● | ||||||||

| 3-Jaw chuck | Φ380 | ★ | ★ | ★ | ★ | ★ | ★ | |||||||

| Φ400 | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||

| Φ500 | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||

| 4-Jaw chuck | Φ400 | ★ | ★ | ★ | ★ | ★ | ★ | |||||||

| Φ500 | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||

| Φ630 | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||

| Φ800 | ★ | ★ | ||||||||||||

| Φ1000 | ★ | |||||||||||||

| Steady rest | Φ160-350 | ★ | ★ | |||||||||||

| Φ130-480 | ★ | ★ | ||||||||||||

| Φ100-450 | ★ | ★ | ||||||||||||

| Φ150-500 | ★ | ★ | ||||||||||||

| Φ300-640 | ★ | ★ | ||||||||||||

| Taper attachment and thread cutting dial | L=500 | ★ | ★ | ★ | ★ | ★ | ★ | |||||||

| Digital Display unit | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||

| Adjustable pads | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||

| ● Standard accessories ★Optional accessories Note:The lathes CW6263B and CW62638/750mm/150mm are not accompanied with optional accessories for a follow rest or center rest.lt is equipped with two center rests when maximum turning diameter of the lathe is ≥1000mm,and length between 8000mm-10000mm; and it may be equipped with a blocking iron when maximum turning diameter of the lathe is ≥1000mm,and length not less than 8000mm. | ||||||||||||||