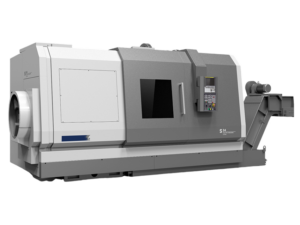

Home » Products » MACHINES » Conventional Machine Tool » Manual Lathe Machine » S1 Series S1-262A 1000mm 1500mm 3000mm

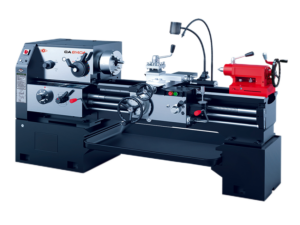

S1 Series S1-262A 1000mm 1500mm 3000mm

The machine tool is a special machine tool which is mainly used for lathe work of pipe thread, and isalso used for works such as cylindrical surface turning, boring and plane machining, etc.

Home » Products » MACHINES » Conventional Machine Tool » Manual Lathe Machine » S1 Series S1-262A 1000mm 1500mm 3000mm

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| Main specifications: | ||||||

|---|---|---|---|---|---|---|

| Height of spindle centerline to bed guideway face: | 450 mm | |||||

| Height of spindle centerline to the ground: | 1150 mm | |||||

| Max. external diameter of pipe to be turned | 340 mm | |||||

| Max. center distance(when tailstock is used): | 1000mm;1500mm;3000mm | |||||

| Max. turning length (travel of the carriage): | 1000mm;1500mm;3000mm | |||||

| Spindle | ||||||

| Diameter of spindle bore | 355 mm | |||||

| Steps of spindle speed | 12 | |||||

| Range of spindle speed | 5.6-254r/min(50Hz) | |||||

| 7-305 r/min(60Hz) | ||||||

| Feed system | ||||||

| Number of feeds in longitudinal and traverse direction | 32 | |||||

| Range of longitudinal feed | 0.095~1.44 mm/r | |||||

| Range of traverse feed | 0.095~1.44 mm/r | |||||

| Threads in Inch system: | ||||||

| Number: | 26 (Standard configuration) | |||||

| Range: | 1-14t/in (Standard configuration) | |||||

| Number: | 40 (Special order) | |||||

| Range: | 1/2~28 t/in (Special order) | |||||

| Threads in Metric system: | ||||||

| Number: | 22 | |||||

| Range: | 1~15 mm | |||||

| Module thread: | ||||||

| Number: | 21 | |||||

| Range: | 0.5~7.5 mm | |||||

| Thread in Diametral-pitch system | ||||||

| Number: | 20 | |||||

| Range: | 28~2 t/in | |||||

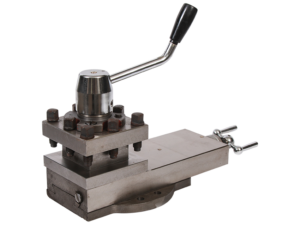

| Saddle and carriage | ||||||

| Vertical distance from spindle centerline to bearing face of the tools | 33 mm | |||||

| Size of tool section | 32×32 mm | |||||

| Max. swing angle of middle rest | ±90° | |||||

| Max. travel of cross slide | 300 mm | |||||

| Max. travel of compound rest | 200 mm | |||||

| Rapid speed of carriage in longitudinal and traverse direction | 4 m/min | |||||

| Taper attachment | ||||||

| Max. continuous turning taper length of ratio 1:4 | 500 mm | |||||

| Max. cross travel | 100 mm | |||||

| Apron | ||||||

| Teeth per inch of leadscrew | 2 t | |||||

| Outer diameter of leadscrew | 55 mm | |||||

| Outer diameter of feed rod | 38 mm | |||||

| Module of rack | 3 mm | |||||

| Tailstock | ||||||

| Diameter of center sleeve | 100 mm | |||||

| Travel of center sleeve | 250 mm | |||||

| Taper of center sleeve | Morse No.5 | |||||

| Taper of center | Morse No.5 | |||||

| Traverse travel of tailstock | ±15 mm | |||||

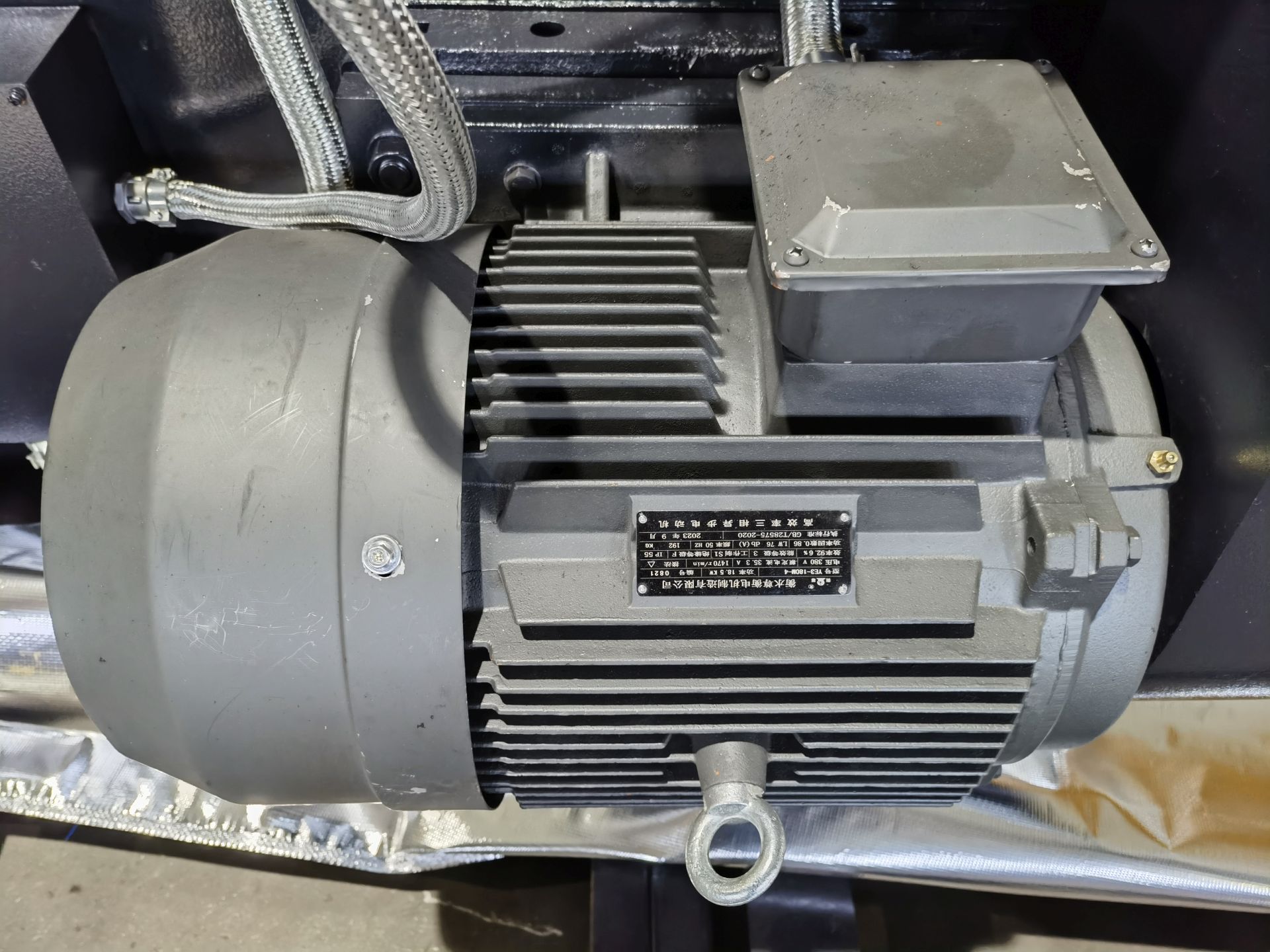

| Power system | ||||||

| Main motor: (The voltage frequency of motor and pump is in accordance with the voltage frequency of the customer’s order) | ||||||

| Type | Y180-4 B3 | |||||

| Power | 18.5 kW | |||||

| Speed | 1500 r/min | |||||

| V -belts | ||||||

| Size | B-1800 (internal circle length) | |||||

| Number | 5 | |||||

| Type of clamping motor | Y112M-4 B3 | |||||

| Power | 4 kW | |||||

| Speed | 1450 r/min | |||||

| V-belts | ||||||

| Size | B-1245 | |||||

| Number | 2 | |||||

| Rapid motor: | ||||||

| Type | Special motor for middle flange | |||||

| Power | 1.1 kW | |||||

| Speed | 1450 r/min | |||||

| Motor for hydraulic pump: | ||||||

| Type | Y802-4 B3 | |||||

| Power | 0.75 kW | |||||

| Speed | 1380 r/min | |||||

| Control and lubricating system | ||||||

| Type of gear pump | CB-B10 | |||||

| Delivery capacity of gear pump | 0.01m3/min | |||||

| Pressure | 2.5Mpa | |||||

| Cooling device (attachment) | ||||||

| Cooling pump | ||||||

| Type | AOB-25 | |||||

| Power | 90W | |||||

| Flow | 0.025 m3/min | |||||

| Overall dimensions and gross weight of the machine | ||||||

| Size: | 1000mm | 1500mm | 3000 mm | |||

| Height: | 1620mm | 1620mm | 1620 mm | |||

| Width: | 1908mm | 1974mm | 1974 mm | |||

| Length: | 3700mm | 4190mm | 5690 mm | |||

| Net weight | Approx. 7876kg | Approx. 8500kg | Approx. 11200kg | |||

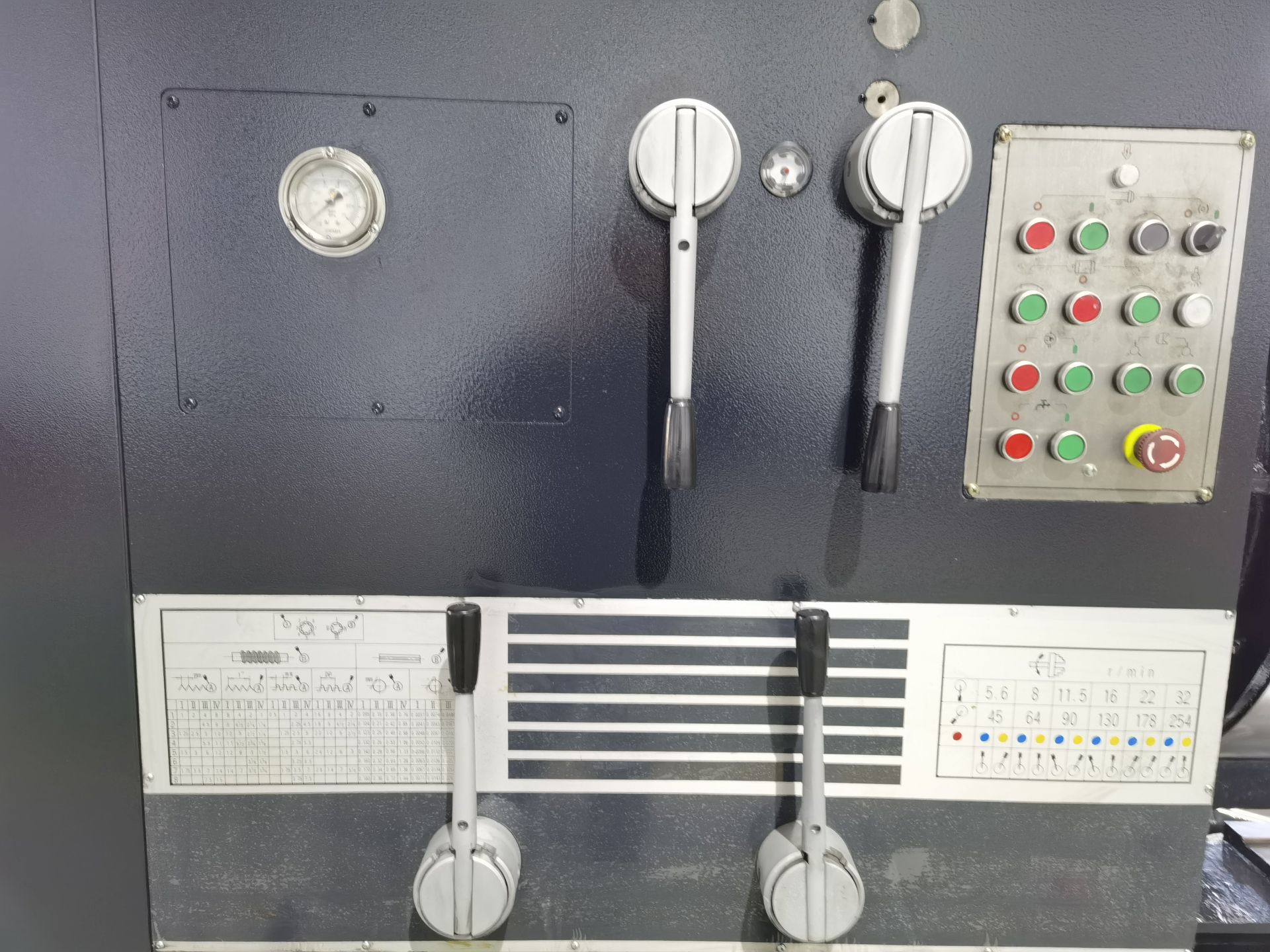

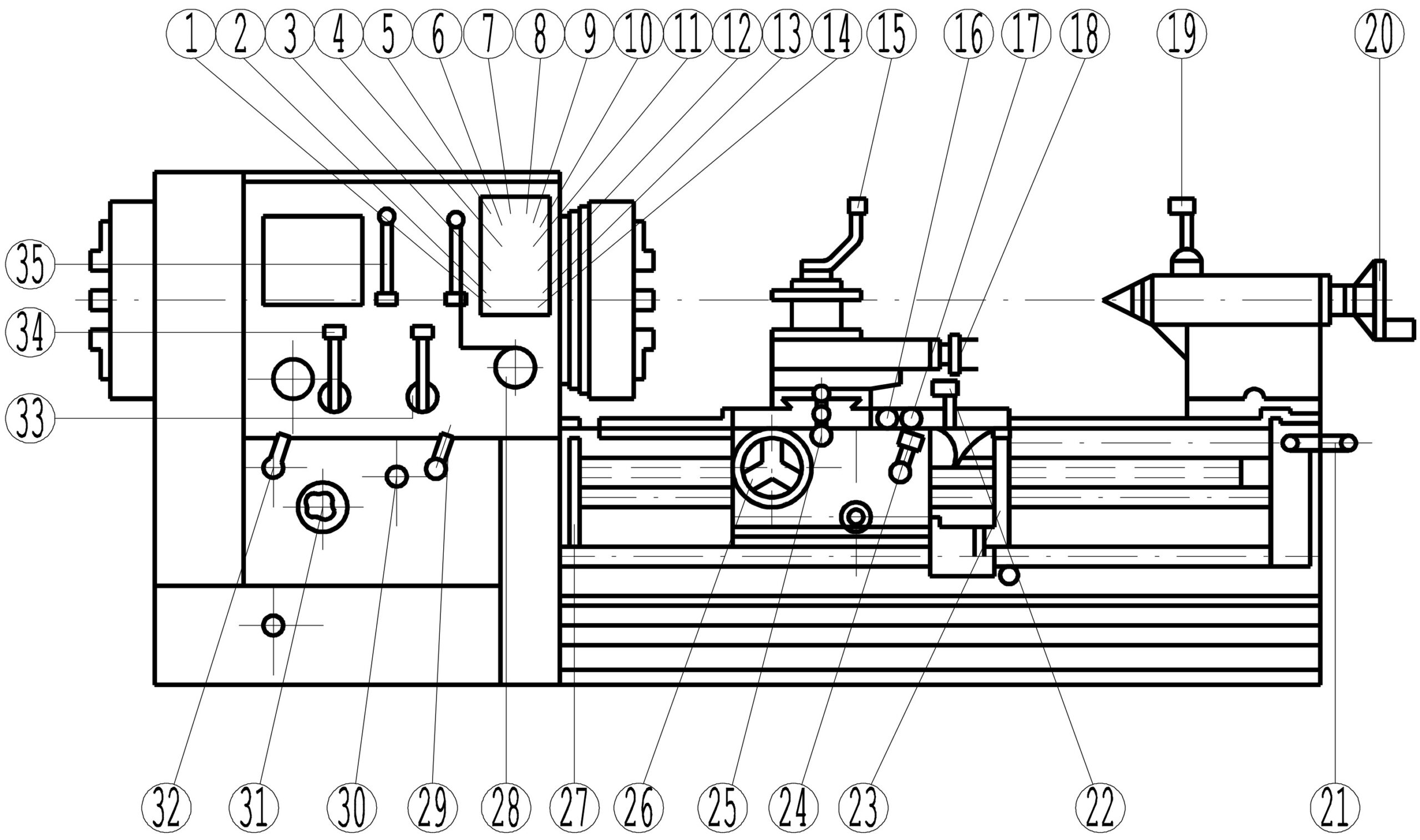

| Arrangement of the control levers of the machine | ||

|---|---|---|

| No. | Name | Function |

| 1 | Button | Selecting button for spindle brake |

| 2 | Button | Button for spindle jog |

| 3 | Button | Button for spindle start |

| 4 | Button | Button for spindle stop |

| 5 | Button | Button for spindle forward |

| 6 | Button | Button for main motor stop |

| 7 | Button | Button for spindle reverse |

| 8 | Button | Button for starting hydraulic pump |

| 9 | Button | Button for starting cooling pump |

| 10 | Button | Button for starting hydraulic pump stop |

| 11 | Button | Button for cooling stop |

| 12 | Button | Button for clamping chuck |

| 13 | Button | Button for releasing chuck |

| 14 | Button | Button for general stopping the machine |

| 15 | Handle | Handle for indexing and tightening of square tool post |

| 16 | Button | Button for spindle start |

| 17 | Button | Button for spindle stop |

| 18 | Handle | Handle for moving upper rest |

| 19 | Lever | Lever for clamping and releasing center sleeve |

| 20 | Handwheel | Handwheel for moving tailstock sleeve |

| 21 | Lever | Lever for tailstock moving |

| 22 | Button and lever | Button for rapid motor and control lever for longitudinal and traverse moving |

| 23 | Lever | Control lever for big leadscrew forward/reverse |

| 24 | Handle | Control lever for split nut |

| 25 | Handle | Handle for moving lower rest |

| 26 | Handwheel | Handwheel for longitudinal moving of carriage |

| 27 | Lever | Big leadscrew forward/reverse |

| 28 | Handle | Handle for engaging/un-engaging front and rear chucks |

| 29 | Lever | Lever for engaging leadscrew and feed rod |

| 30 | Lever | Lever for adjustment of pitch and feed rate |

| 31 | Hand wheel | handwheel for adjustment of pitch and feed rate |

| 32 | Lever | Exchange lever for Metric and inch thread |

| 33 | Lever | Speed change lever for spindle |

| 34 | Lever | Speed change lever for spindle |

| 35 | Lever | Speed change lever for spindle |

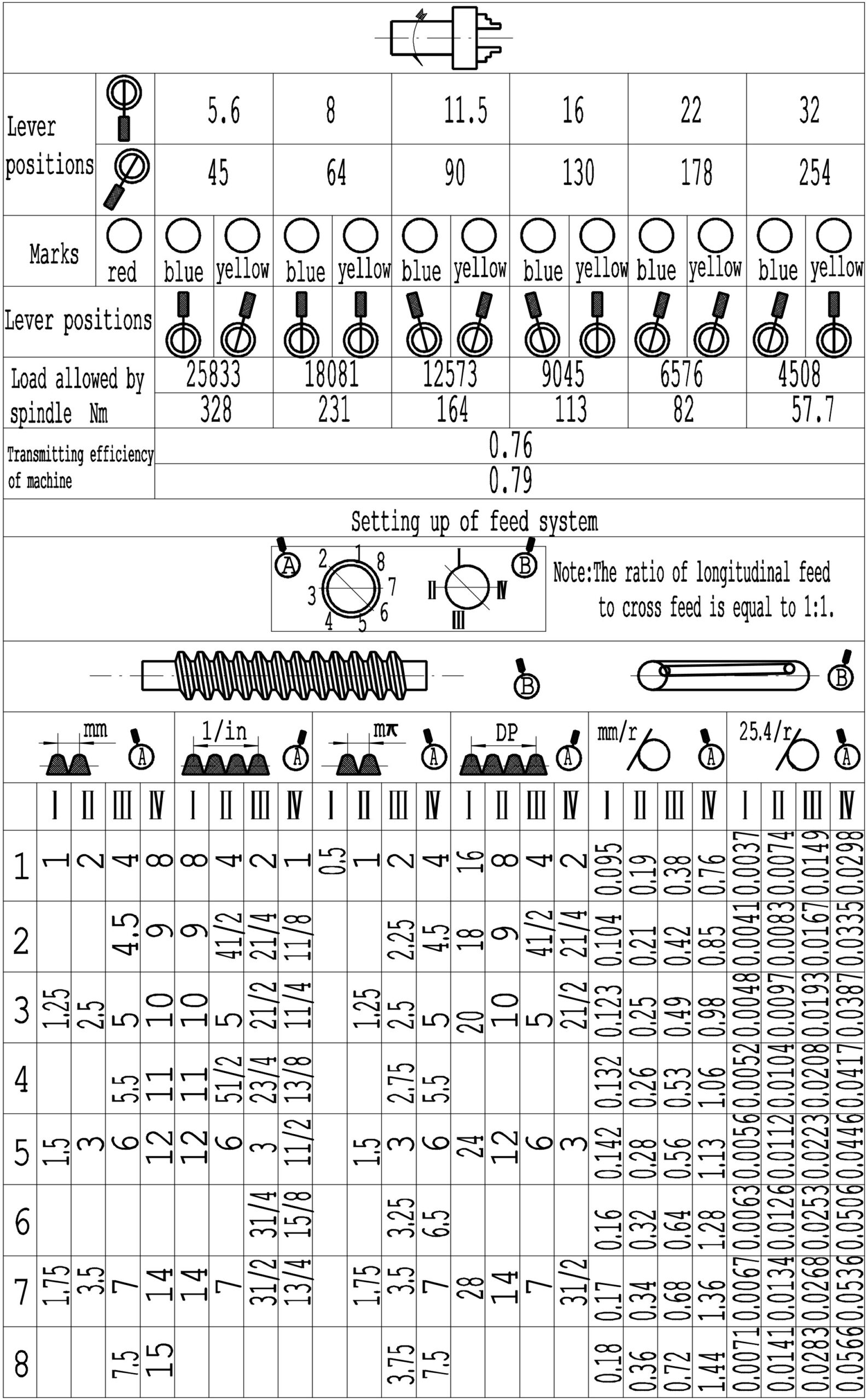

Setting-up of Spindle Revolution and Its Working Capacity(50Hz; 1-14t/in)

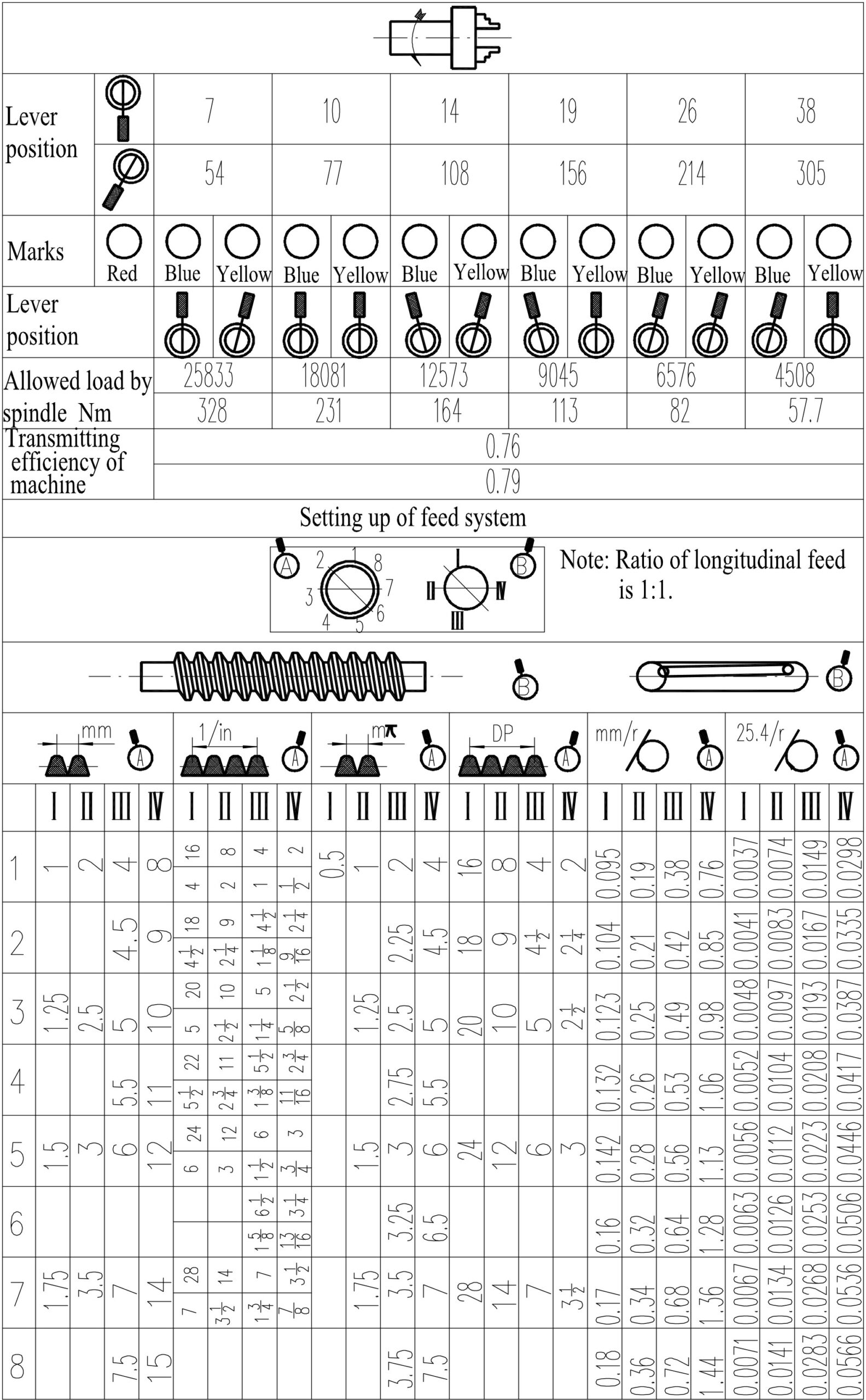

Setting-up of Spindle Revolution and Its Working Capacity(60Hz; 1/2-28t/in)

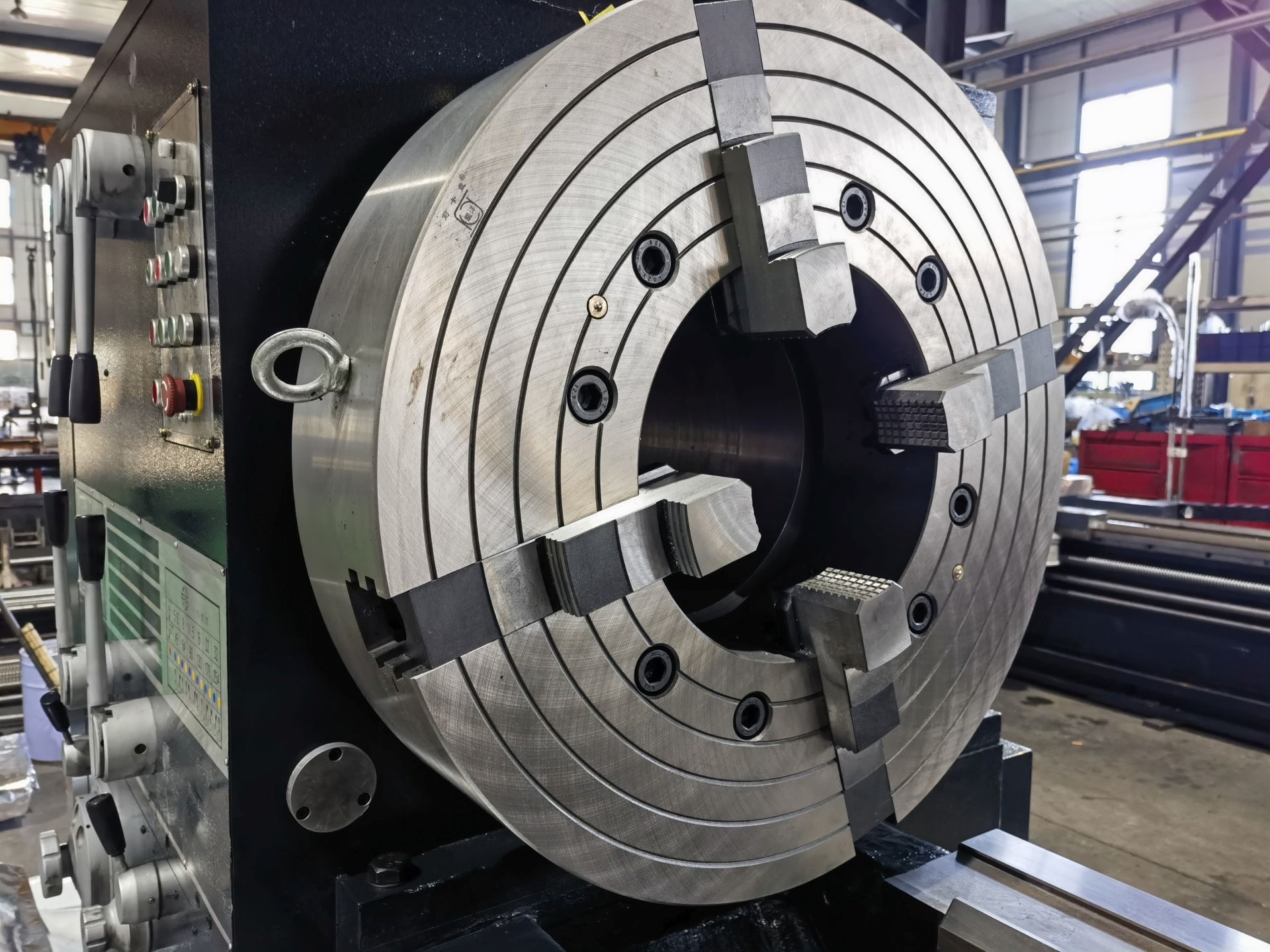

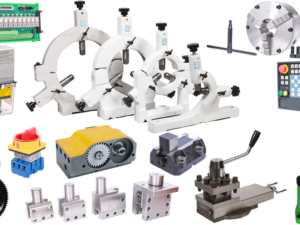

- Large Aperture Spindle

- Front and Rear Dual Chucks

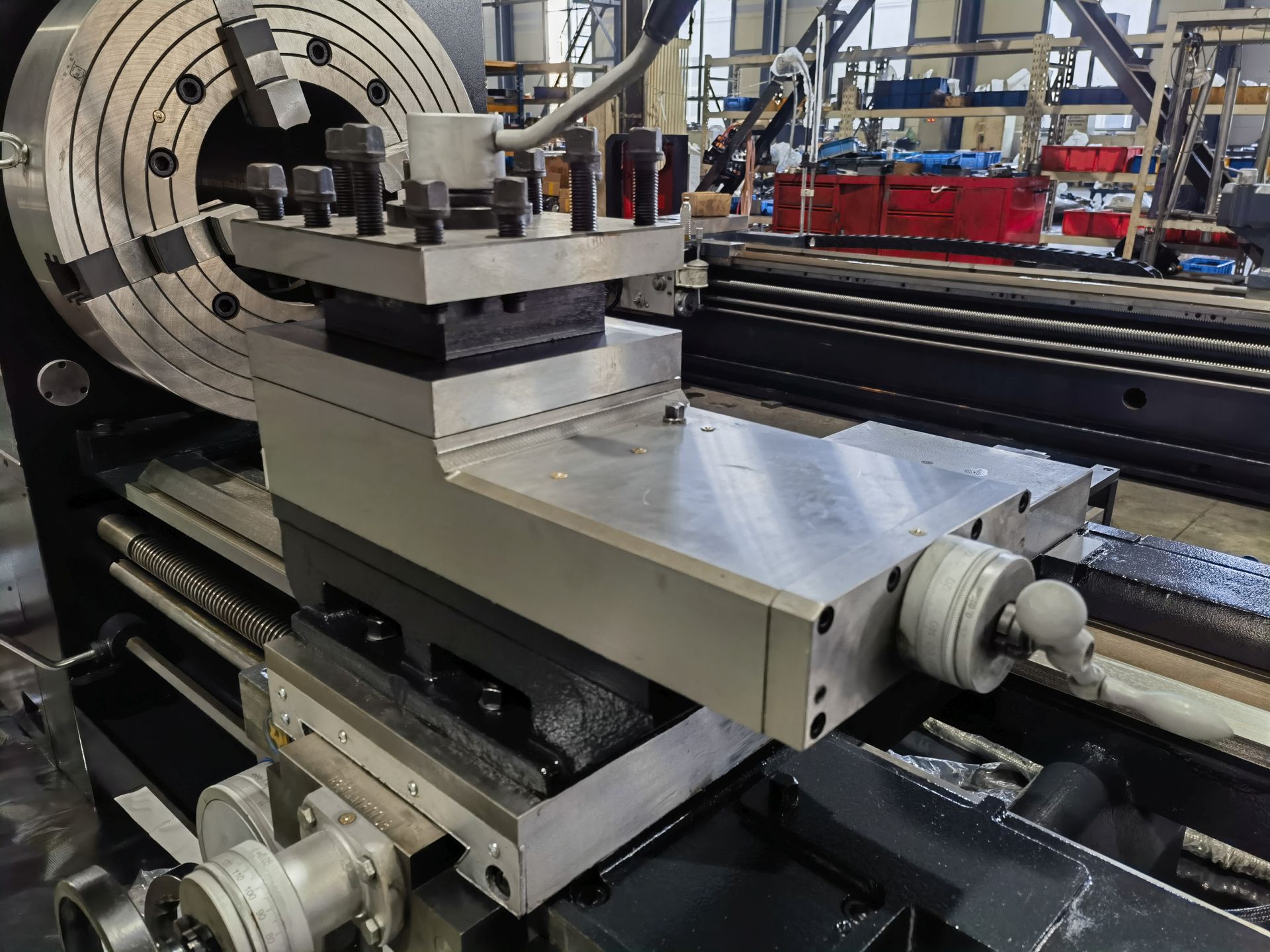

- Vertical 4 Positions Turret

- Bed Guide Rail

- Manual Tailstock

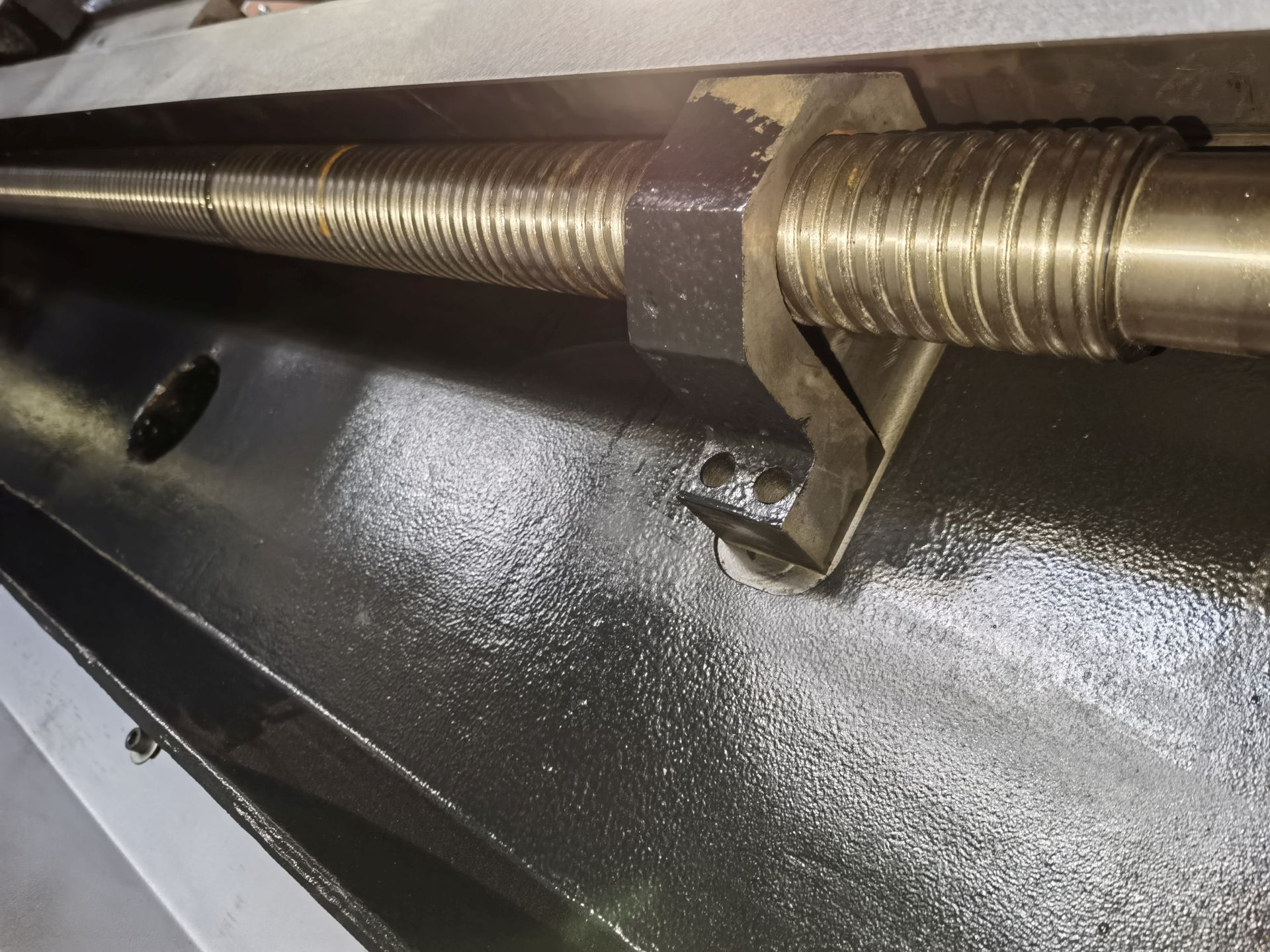

- Leadscrew

- Control Panel

- Main Motor

- Leadscrew

- Taper Attachment

- Lighting Lamp