Home » Products » MACHINES » Conventional Machine Tool » Manual Vertical Drilling Machine » Z3050 X16 Radial Drilling Machine

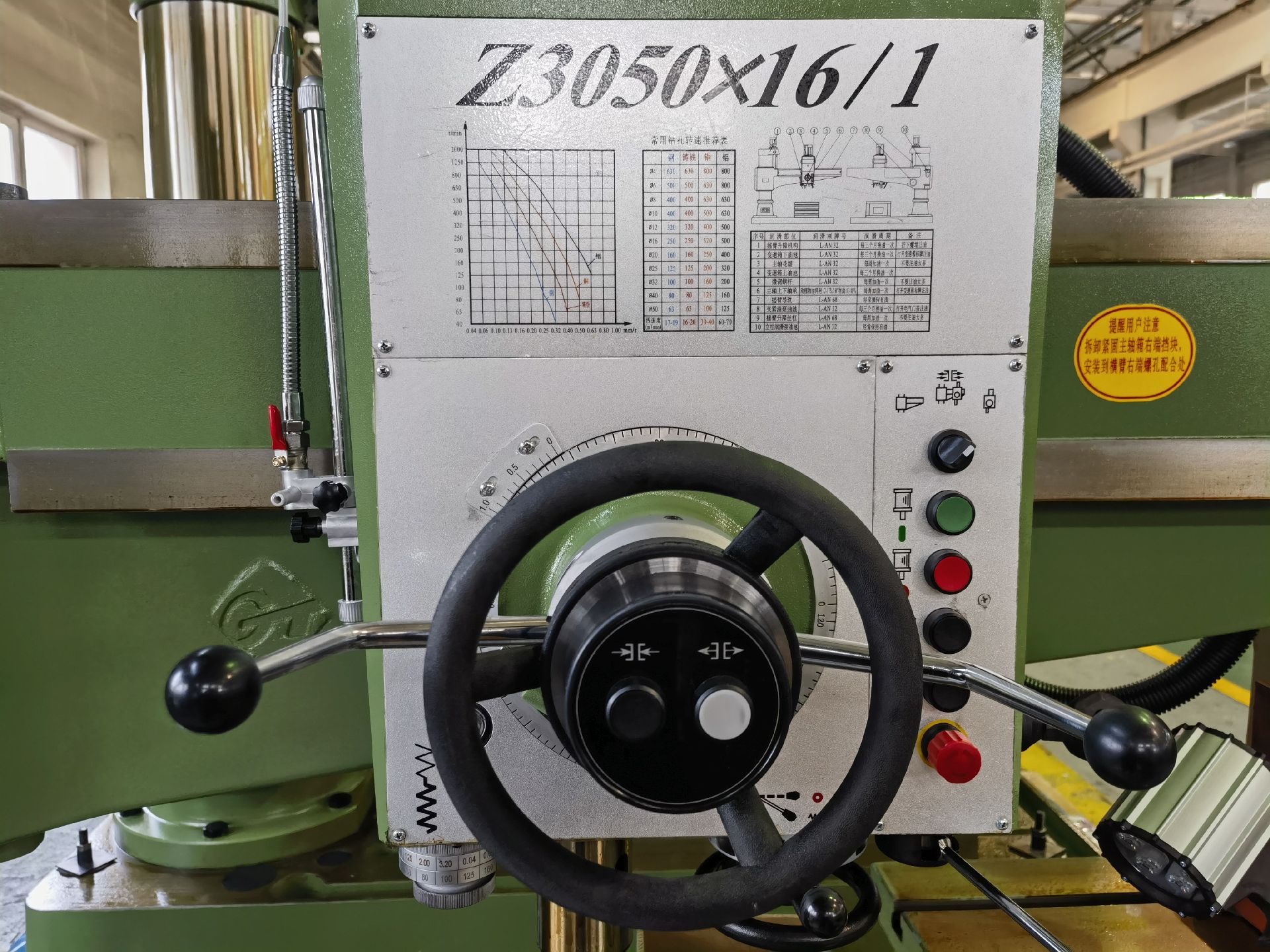

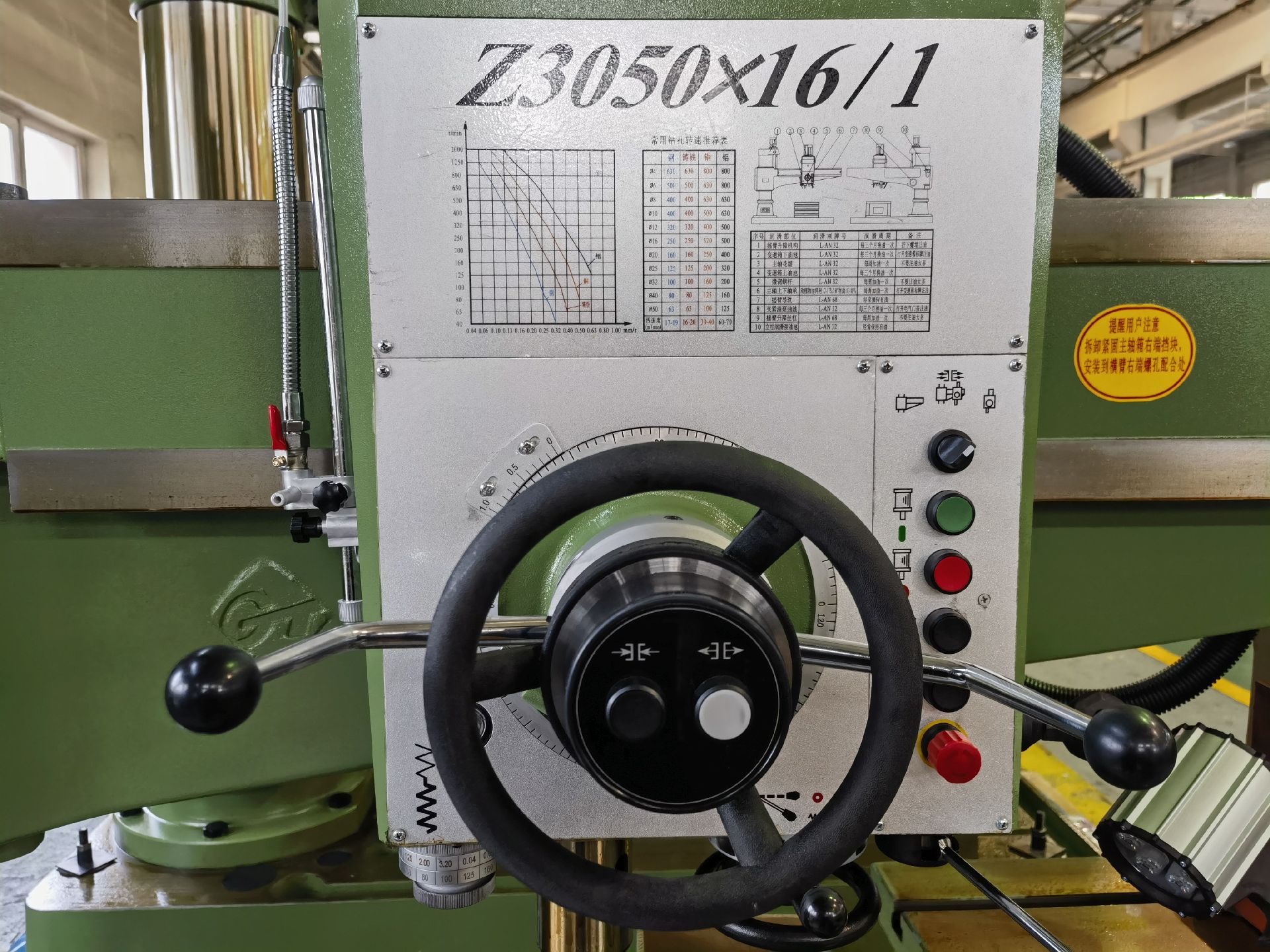

Z3050 X16 Radial Drilling Machine

1. **Versatile Application**: This model of equipment finds wide applications in drilling, reaming, tapping, countersinking, and thread cutting tasks.

2. **Hydraulic Preselection with Variable Speed**: The equipment features hydraulic preselection with variable speed control, offering flexibility in operations.

3. **Hydraulic Power for Clamping**: Hydraulic power is utilized to achieve clamping in various machine components.

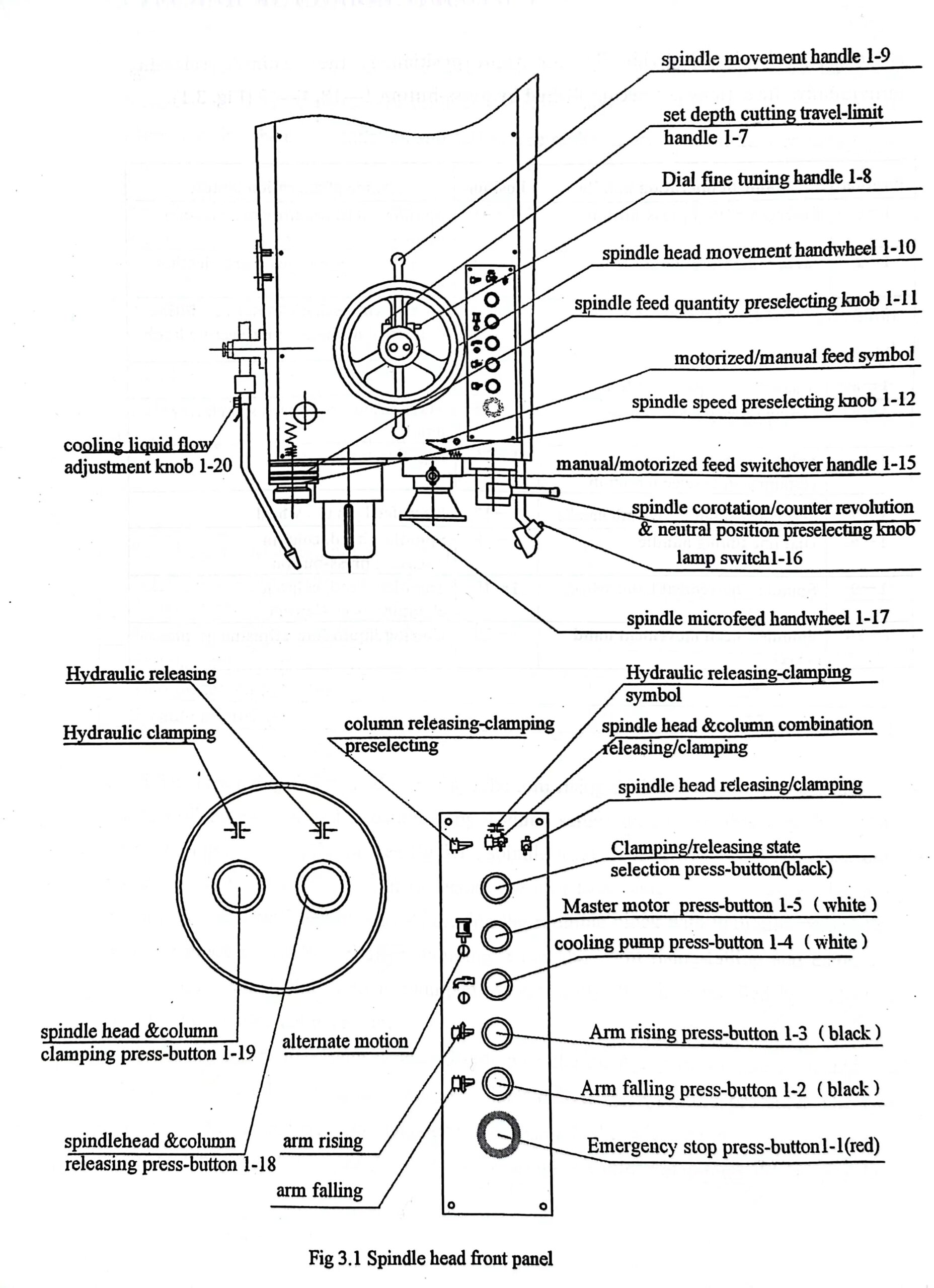

4. **Centralized Control**: Machine, electrical, and hydraulic controls are centralized on the spindle box, making operations convenient and efficient.

5. **Single-Hand Control for Forward and Reverse**: One-handed operation for both forward and reverse movements, simplifying control.

6. **Dual-Column Structure**: The machine is designed with a dual-column structure for added stability and precision.

Home » Products » MACHINES » Conventional Machine Tool » Manual Vertical Drilling Machine » Z3050 X16 Radial Drilling Machine

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| Specifications | ||||||

|---|---|---|---|---|---|---|

| Main size & parameter | Z3040 × 12 (I) (II) | Z3040 × 16 (I) (II) | Z3050 × 10 (I) (II) | Z3050 × 16 (I) (II) | ||

| Max. diameter of hole drilled | 40 mm | 50 mm | 50 mm | 50 mm | ||

| Distance from center line of spindle to the bus of the column | Max. | 1200 mm | 1600 mm | 1200 mm | 1600 mm | |

| Min. | 350 mm | 350 mm | 350 mm | 350 mm | ||

| Spindle head horizontal movement distance | 900 mm | 1250 mm | 900 mm | 1250 mm | ||

| Distance from spindle end to baseplate working surface | Max. | Z3040 × 12 (I): 1250mm | Z3040 × 16 (I): 1250mm | Z3050 × 12 (I): 1220mm | Z3050 × 16 (I): 1220mm | |

| Z3040 × 12 (II): 1280mm | Z3040 × 16 (II): 1280mm | Z3050 × 12 (II): 1250mm | Z3050 × 16 (II): 1250mm | |||

| Min. | Z3040 × 12 (I): 350mm | Z3040 × 16 (I): 350mm | Z3050 × 12 (I): 320mm | Z3050 × 16 (I): 320mm | ||

| Z3040 × 12 (II): 380mm | Z3040 × 16 (II): 380mm | Z3050 × 12 (II): 350mm | Z3050 × 16 (II): 350mm | |||

| arm rising-falling distance | 580mm | 580mm | 580mm | 580mm | ||

| arm rising falling speed | 0.02m/s | 0.02m/s | 0.02m/s | 0.02m/s | ||

| arm rotation angle | ±180° | ±180° | ±180° | ±180° | ||

| Spindle conical bore | Morse No.4 | Morse No.4 | Morse No.5 | Morse No.5 | ||

| Spindle rotation speed range | 25-2000r/min | 25-2000r/min | 25-2000r/min | 25-2000r/min | ||

| Spindle rotation speed class | 16 classes | 16 classes | 16 classes | 16 classes | ||

| Spindle feed quantity range | 0.04-3.2mm/r | 0.04-3.2mm/r | 0.04-3.2mm/r | 0.04-3.2mm/r | ||

| Spindle feed quantity class | 16 classes | 16 classes | 16 classes | 16 classes | ||

| Spindle travel | 315mm | 315mm | 315mm | 315mm | ||

| Drilling depth per each rotation of dial | 122mm | 122mm | 122mm | 122mm | ||

| Allowed spindle max. torque | 400N.m | 400N.m | 500N.m | 500N.m | ||

| Allowed spindle max. feed resistance force | 16000N | 16000N | 18000N | 18000N | ||

| Power of master motor | 3Kw | 3Kw | 4Kw | 4Kw | ||

| Power of arm rising-falling motor | 1.5Kw | 1.5Kw | 1.5Kw | 1.5Kw | ||

| Power of hydraulic clamping motor | 0.75Kw | 0.75Kw | 0.75Kw | 0.75Kw | ||

| Power of cooling pump motor | 0.09Kw | 0.09Kw | 0.09Kw | 0.09Kw | ||

| Weight of machine tool (approximate) | 3000Kg | 3500Kg | 3000Kg | 3500Kg | ||

| Dimensions of machine tool (length × width × height) | 2150×1070×2840mm | 2500×1070×2840mm | 2150×1070×2840mm | 2500×1070×2840mm | ||

1. **Drilling Capability**: This radial arm drilling machine can drill holes with a maximum diameter of 50 mm, making it suitable for medium-sized steel structures, metal workpieces, and other materials.

capacity (up to 18,000 N), capable of handling challenging materials and large hole diameters.

drilling at different angles.

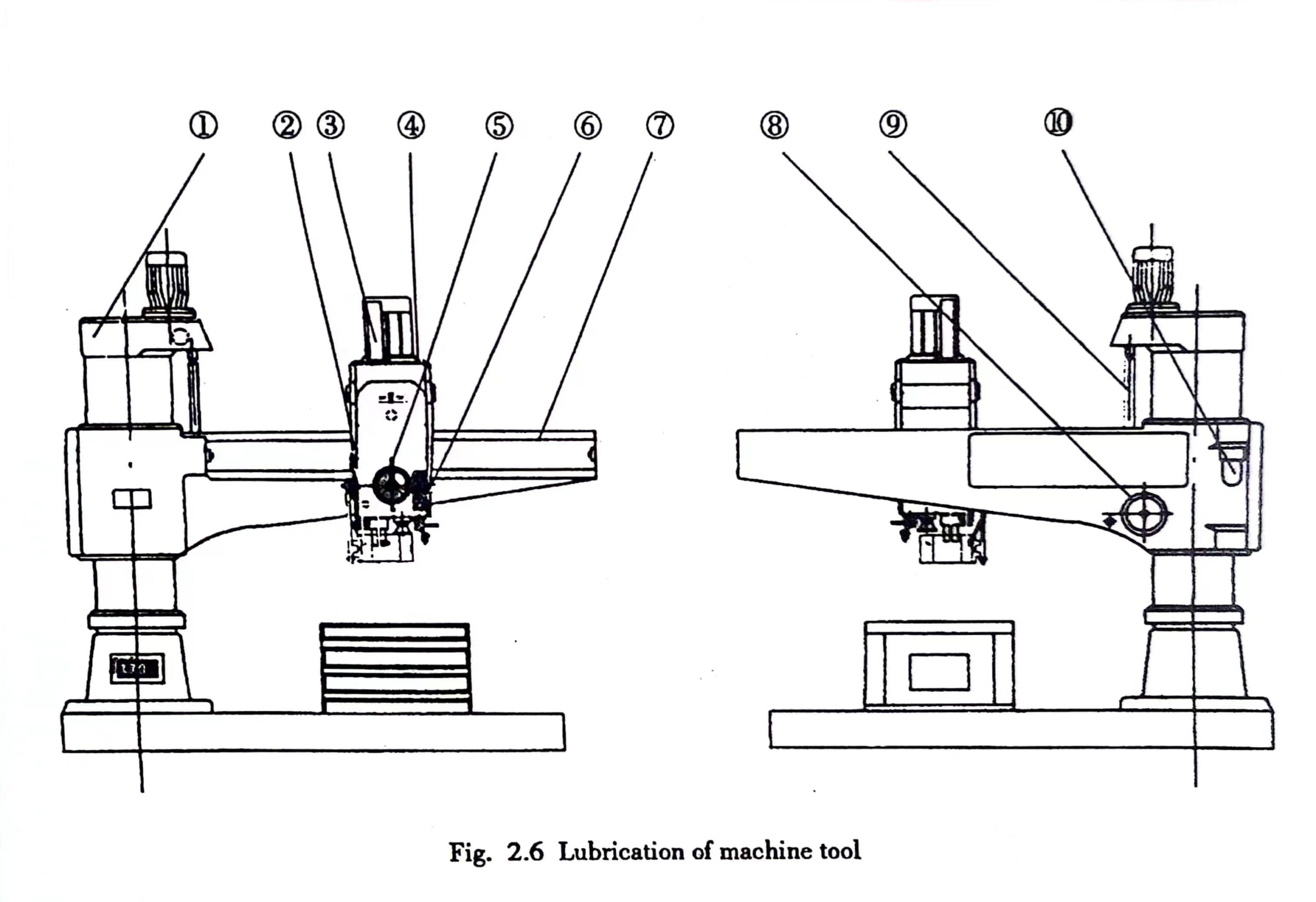

| Lubrication Table | ||||

|---|---|---|---|---|

| Item No. | Lubrication Point | Lubricant trademark number | Lubrication Circle | Remark |

| 1 | arm rising- -falling mechanism | L-AN32 | Change oil once per 3 months | Unscrew the threaded plug when fill oil(about 1000ml) |

| 2 | Gear head lower oil pool | L-AN32 | Chang oil once per 3 months | Open label on gear head for filling oil(about 1600ml) |

| 3 | Spindle spline | L-AN32 | Fill oil once per week | Do not overfill |

| 4 | Gear head upper oil pool | L-AN32 | Chang oil once per 3 months | |

| 5 | Fine adjustment worm | L-AN32 | Fill oil once per month | Do not overfill |

| 6 | Spindle upper & lower bearings | Animal & plant oil calcium soap 12-17%,mineral oil 83-87% | Fill oil once per month | Open label on gear head for filling oil |

| 7 | Rock arm guide | L-AN68 | Always keep oily | |

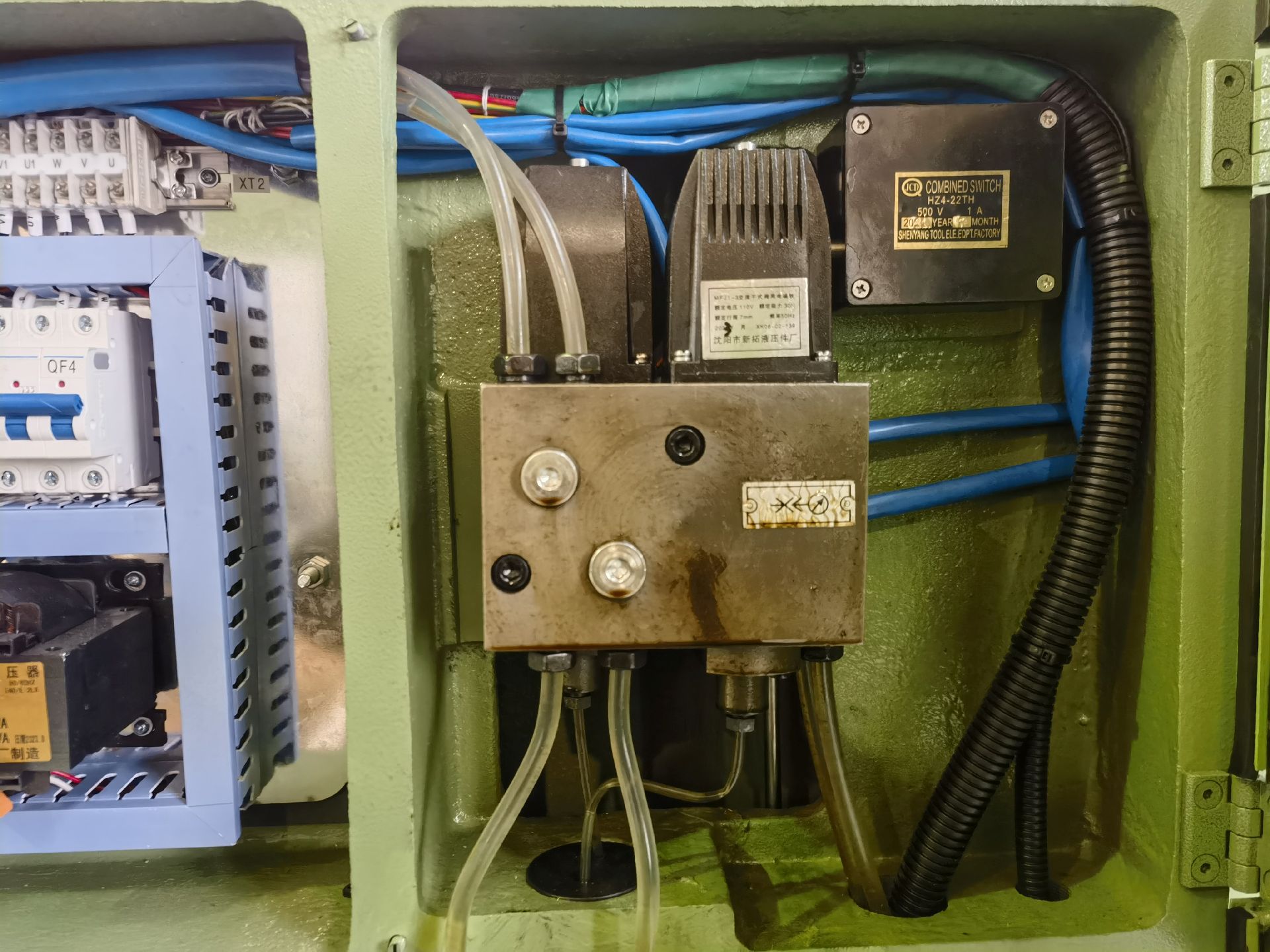

| 8 | Clamping oil pump oil pool | L-AN32 | Chang oil once per 3 months | Open the cover of door of electric appliance cabinet for filling oil |

| 9 | arm rising- -falling guide screw | L-AN68 | Fill oil once per week | Do not overfill |

| 10 | Column lube oil pump oil pool | L-AN32 | Always keep oil | |

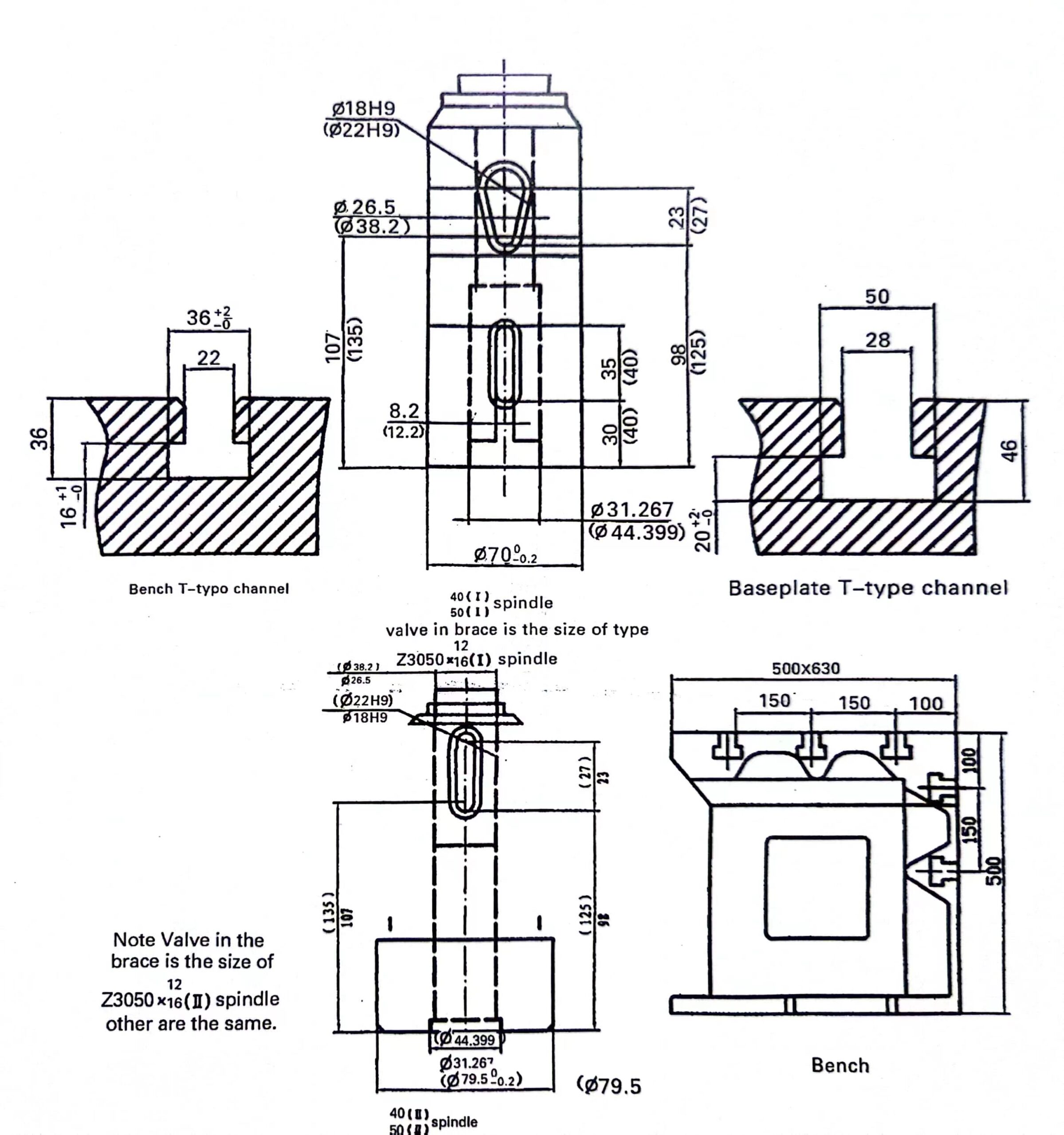

Spindle Differences: Z3050 × 16 (I) vs. Z3050 × 16 (II)

Spindle of Z3050 × 16 (I)

1. Distance from center line of spindle to the bus of the column (Max. and Min. values): These parameters determine the machine tool’s working envelope and available workspace. The maximum distance affects the maximum height of the workpiece the machine tool can accommodate, while the minimum distance impacts the available workspace for the machine. These parameters are crucial for selecting a machine tool suitable for specific workpiece sizes and shapes.

Spindle of Z3050 × 16 (II)

2. Distance from spindle end to baseplate working surface (Max. and Min. values): These parameters establish the range of heights the machine tool can accommodate for workpieces. The maximum and minimum distances affect workpiece clamping, positioning, and machining operations. They are essential for determining whether the machine tool is suitable for processing workpieces with specific height requirements.

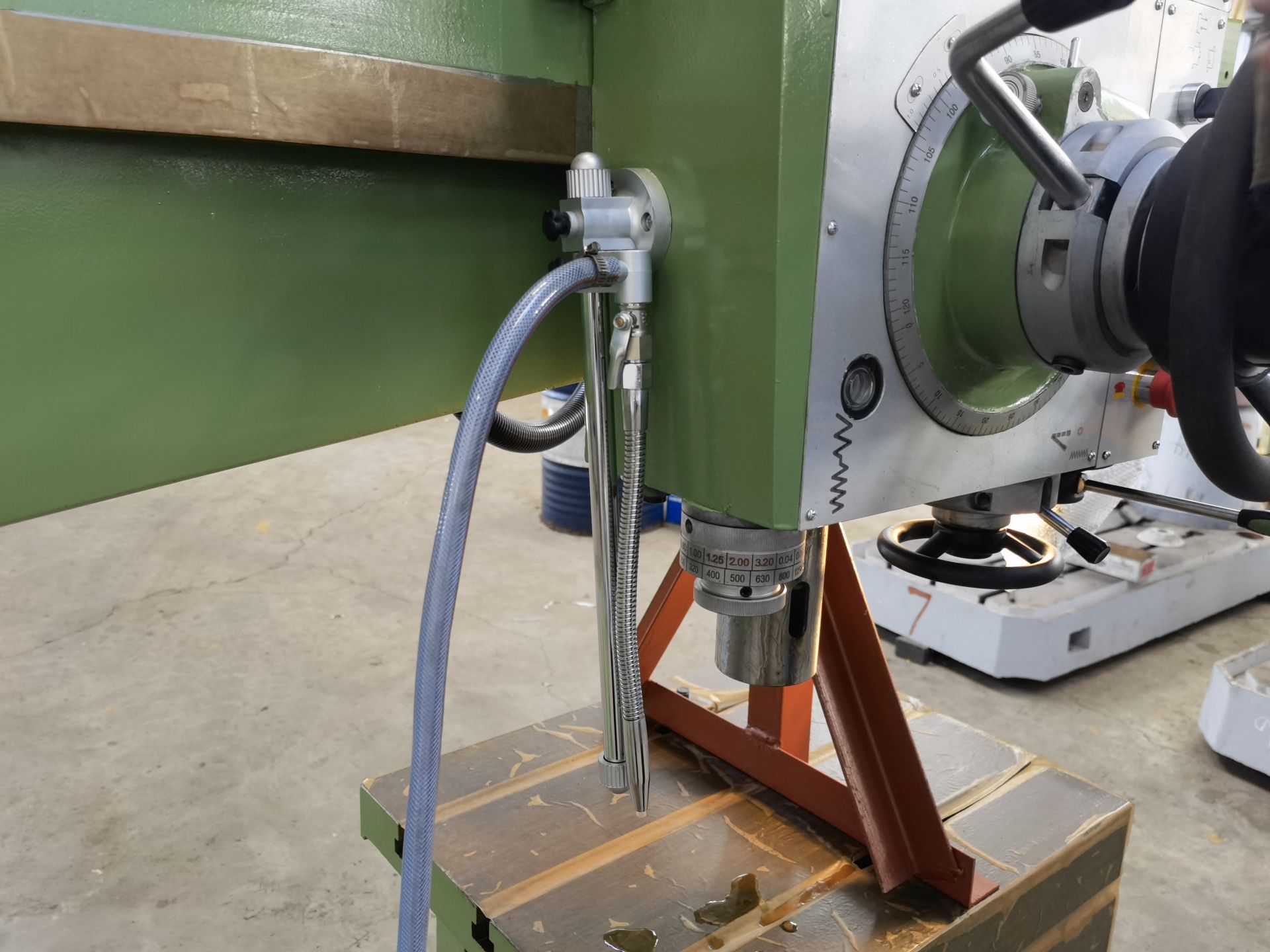

- Machine Tool Nameplate

- Worktable

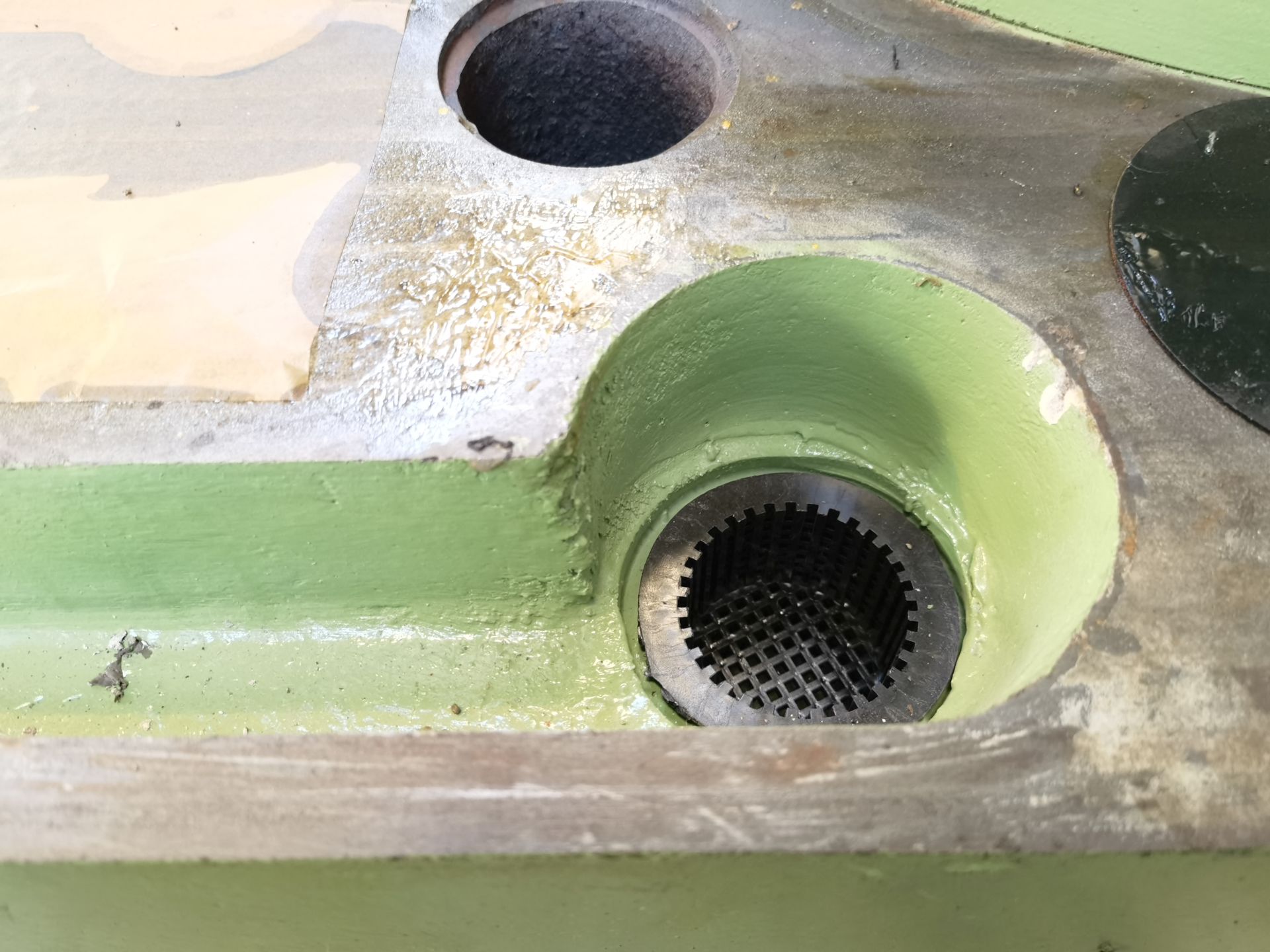

- Coolant Recovery Trench

- Feed Control Lever

- Electrical Distribution Box

- Oil separator sub-assembly

- Lighting Lamp

- Cooling pump

- Main Power Supply

- Headstock

- Cooling Liquid Flowadjustment Knob

- Arm Rising–Falling Mechanism