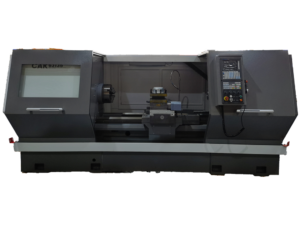

Home » Products » MACHINES » Economic CNC Lathe » SMTCL CAK50 Series

SMTCL CAK50 Series

The machine is mainly used for turning various shaft-type workpieces and disc workpieces, cutting all kinds of threads, arcs,cones and internal and external curvic surfaces of gyro-rotors, and it can meet the need of speed while cutting ferrous and non-ferrous metals at high speed.

Home » Products » MACHINES » Economic CNC Lathe » SMTCL CAK50 Series

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| Item | Unit | CAK50 | ||||

|---|---|---|---|---|---|---|

| Specification | 85L | 85P | 85 | 135 | 186 | |

| Max.parts length | mm | 900 | 890 | 890 | 1390 | 1900 |

| Max cutting length | mm | 850 | 770 | 850 | 1350 | 1860 |

| Max swing diameter over bed | mm | Φ500 | Φ500 | Φ500 | Φ500 | Φ500 |

| Max.swing diameter over slide | mm | Φ280 | Φ300 | Φ300 | Φ300 | Φ300 |

| Max cutting diameter | mm | Φ500 | Φ400 | Φ500 | Φ500 | Φ500 |

| Spindle nose type | A2-8 | A2-8 | A2-8 | A2-8 | A2-8 | |

| Chuck diameter | mm | Φ250 | Φ250 | Φ250 | Φ250 | Φ250 |

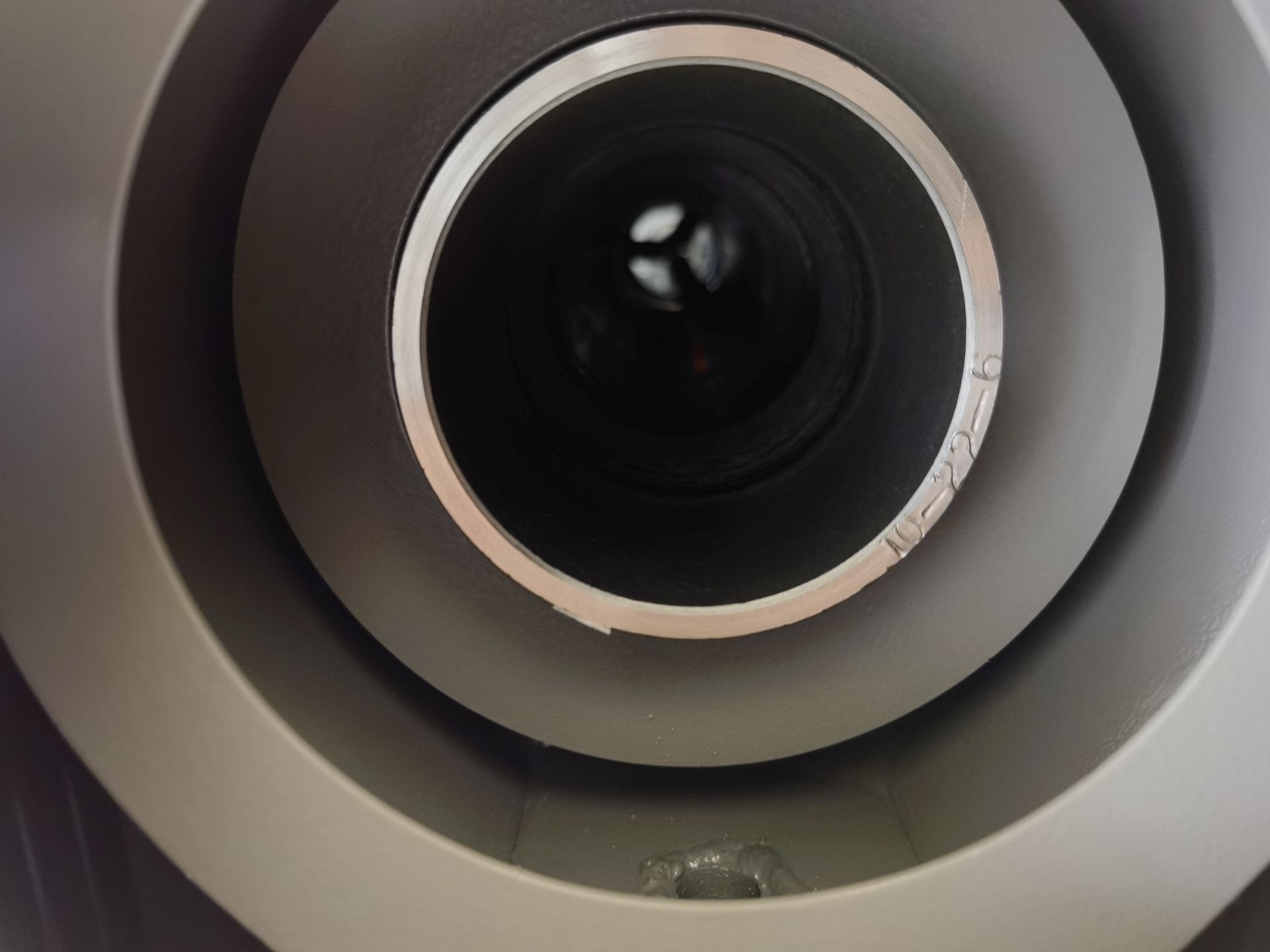

| Spindle bore | mm | Φ53 | Φ80 | Φ78 | Φ78 | Φ78 |

| Spindle speed range (Auto 3 step) | r/min | 15-2200 | 15-2200 | 15-2200 | ||

| Spindle speed range (manual stepless) | r/min | 100-1800 | 22-1800 | 22-1800 | 22-1800 | |

| Spindle speed range (Auto 3 step,12 grades) | r/min | 40-1800 | 40-1800 | 40-1800 | ||

| Spindle speed range (Single spindle) | r/min | 30-2500 | ||||

| Rated power of main motor | kw | 7.5 (frequency conversion) | 11 (Main servo motor) | 7.5 (Main servo motor) | 7.5 (Main servo motor) | 7.5 (Main servo motor) |

| Rated power of main motor(S series) | kw | 6.5/8 (Dual-speed) | 6.5/8 (Dual-speed) | 6.5/8 (Dual-speed) | ||

| Tailstock quill diameter | mm | Φ75 | Φ75 | Φ75 | Φ75 | Φ75 |

| Tailstock quill travel | mm | 150 | 150 | 150 | 150 | 150 |

| Turret type | Vertical 4 positions | Horizontal 6 positions | Vertical 4 positions | Vertical 4 positions | Vertical 4 positions | |

| Tool shank size | mm | □25×25 | □25×25 | □25×25 | □25×25 | □25×25 |

| X/Z axis rapid traverse | m/min | 6/12 | 6/12 | 6/12 | 6/12 | 6/12 |

| Machining accuracy | IT6~IT7 | IT6~IT7 | IT6~IT7 | IT6~IT7 | IT6~IT7 | |

| Machine net weight | kg | 2200 | 2800 | 2800 | 3000 | 3400 |

| Overall dimension (LxWxH) | mm | 2470x1500x1580 | 2770x1700x1735 | 2770x1700x1735 | 3270x1700x1735 | 3870x1700x1735 |

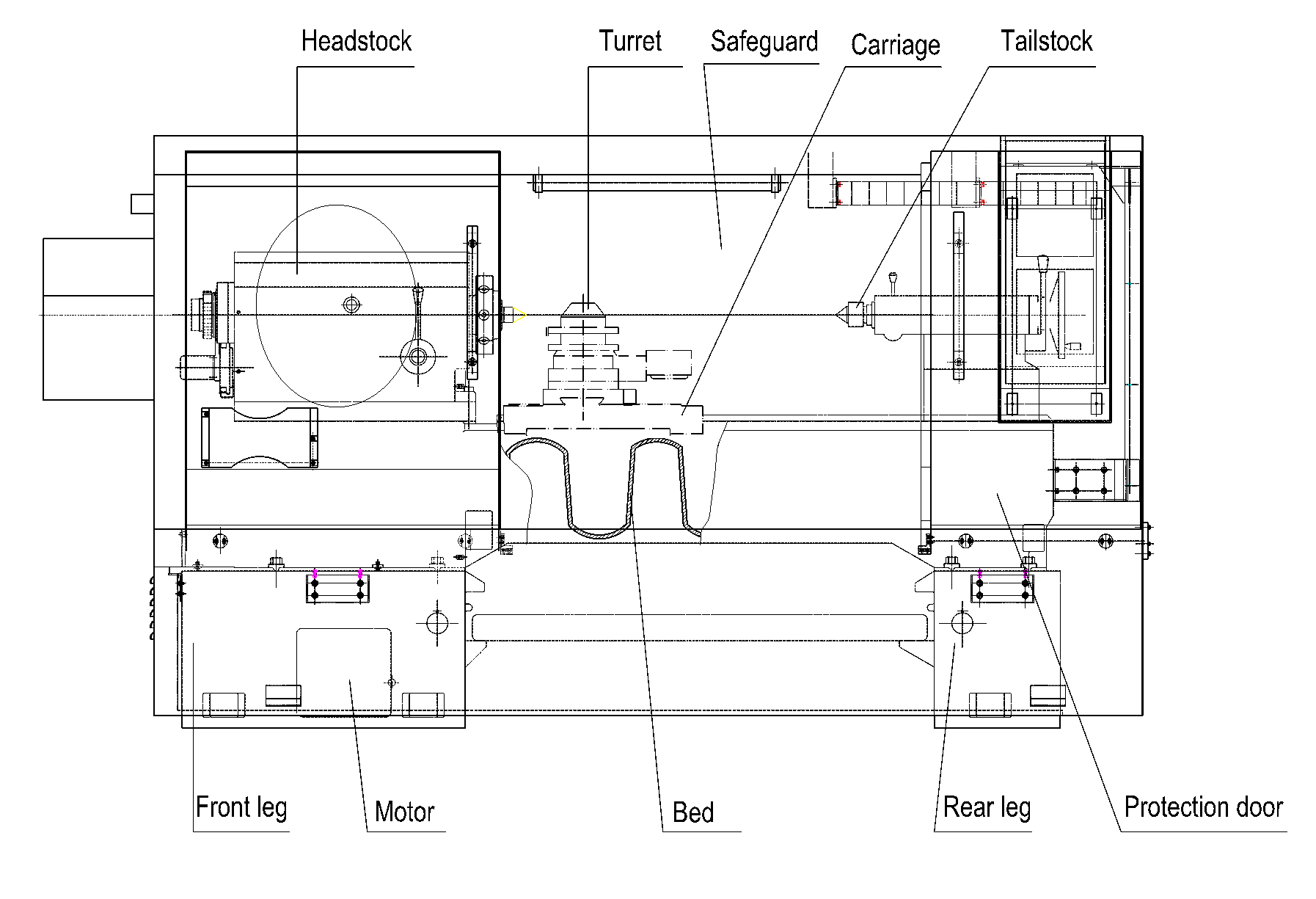

Layout of the Machine

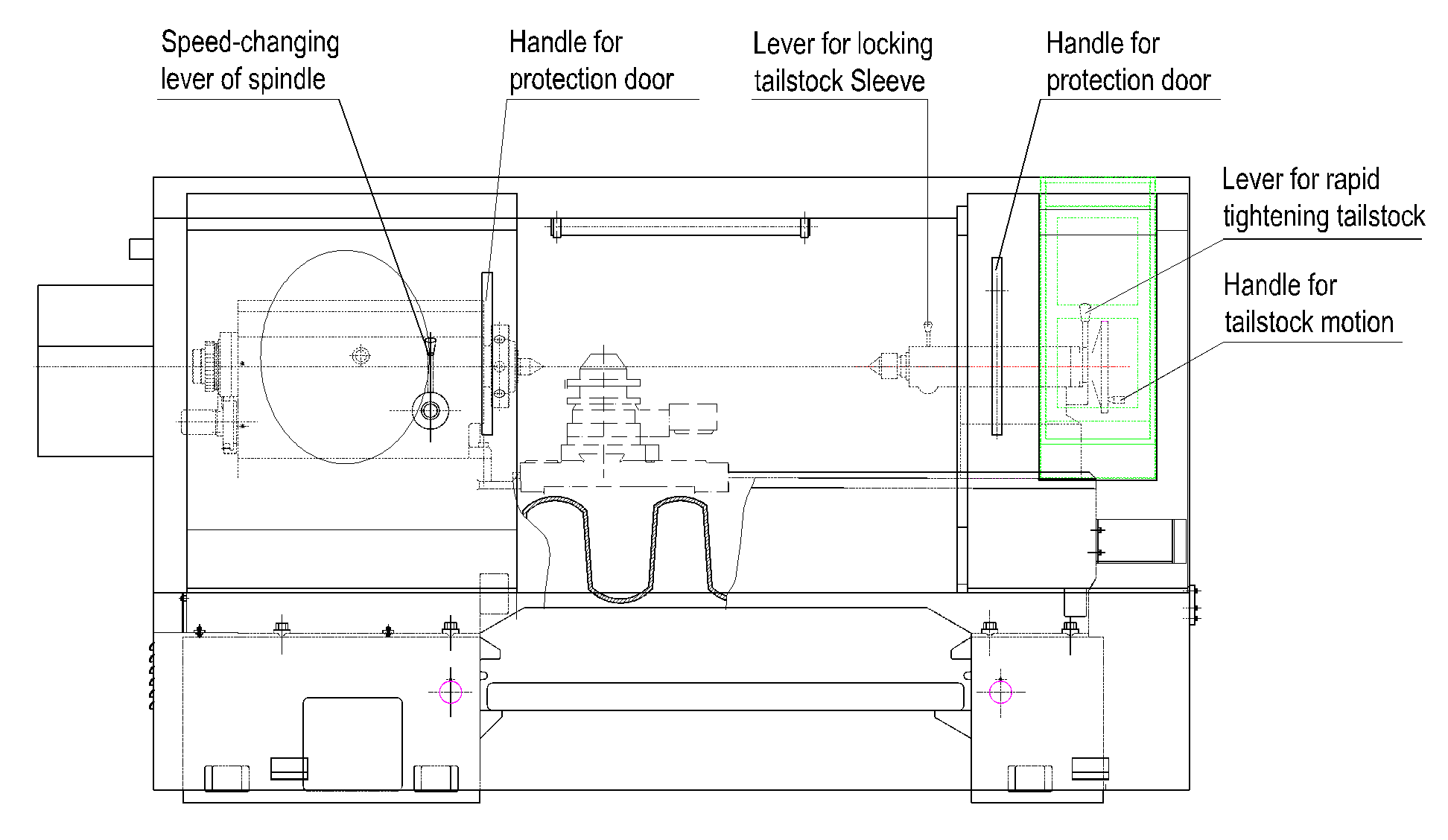

Control Handles of Machine

- Spindle

- Manual Chuck

- Customizable CNC Operating System

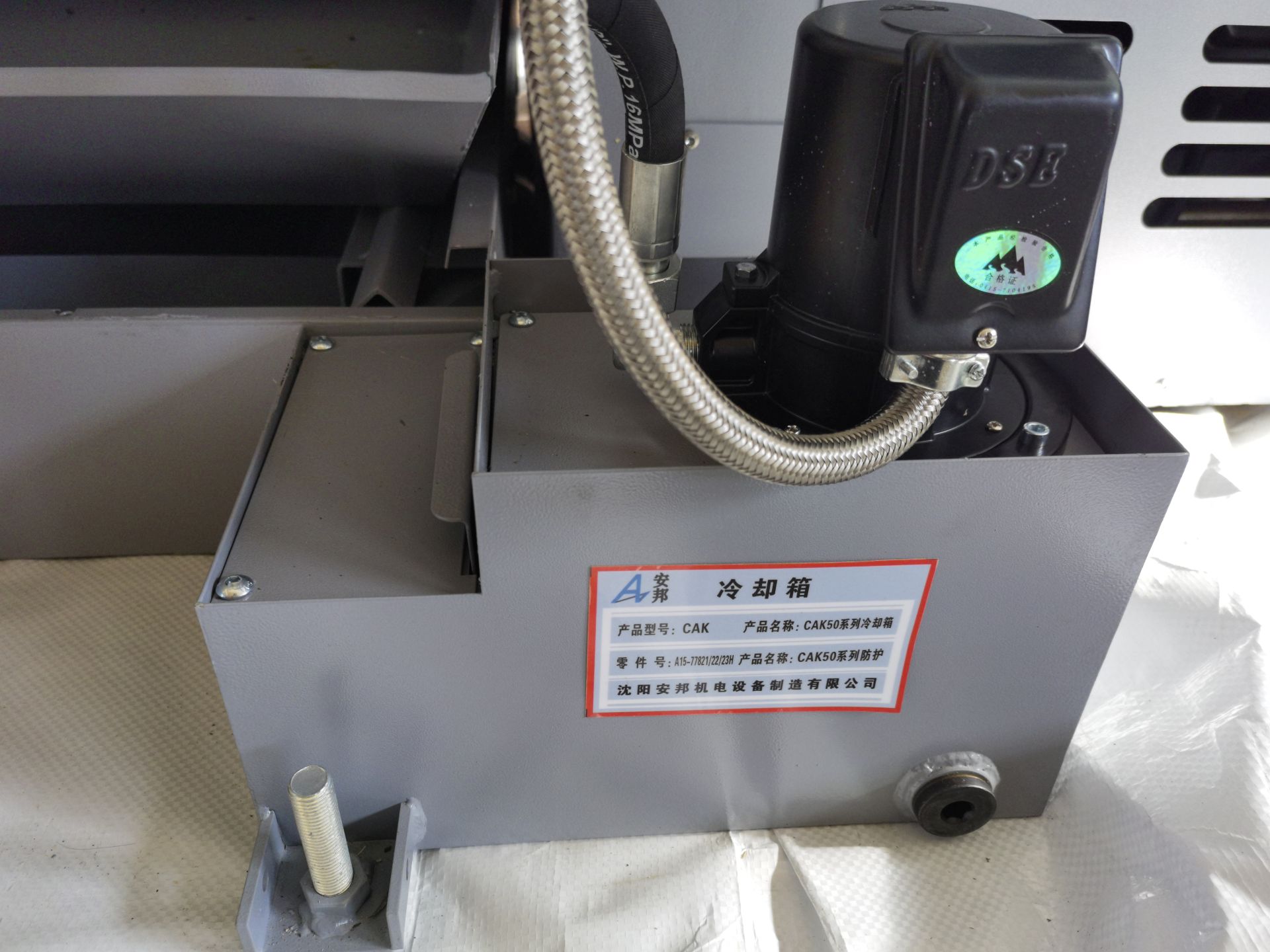

- Coolant Tank

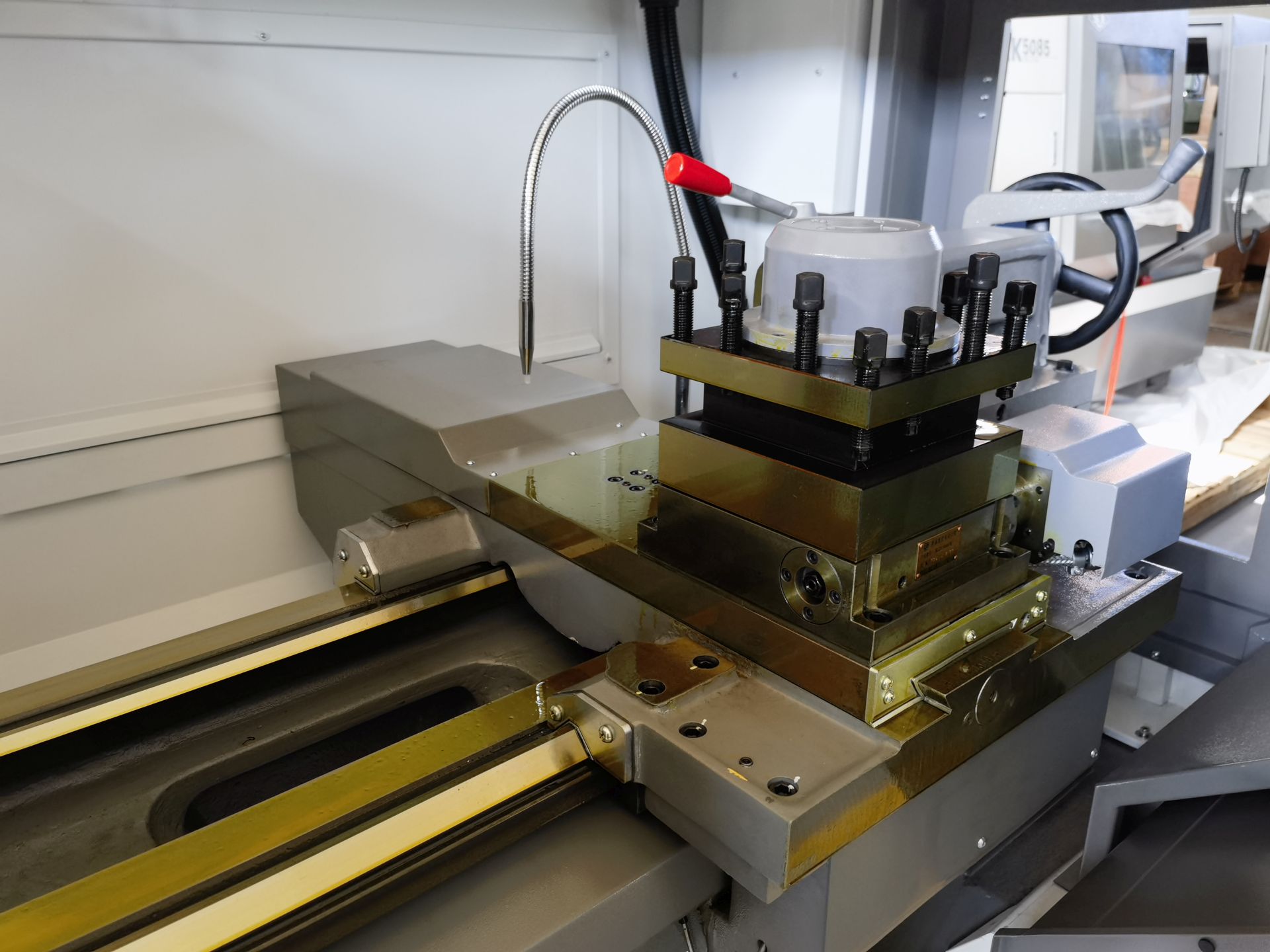

- Vertical 4-Positon Turret

- Lubrication Station

- Manual Tailstock

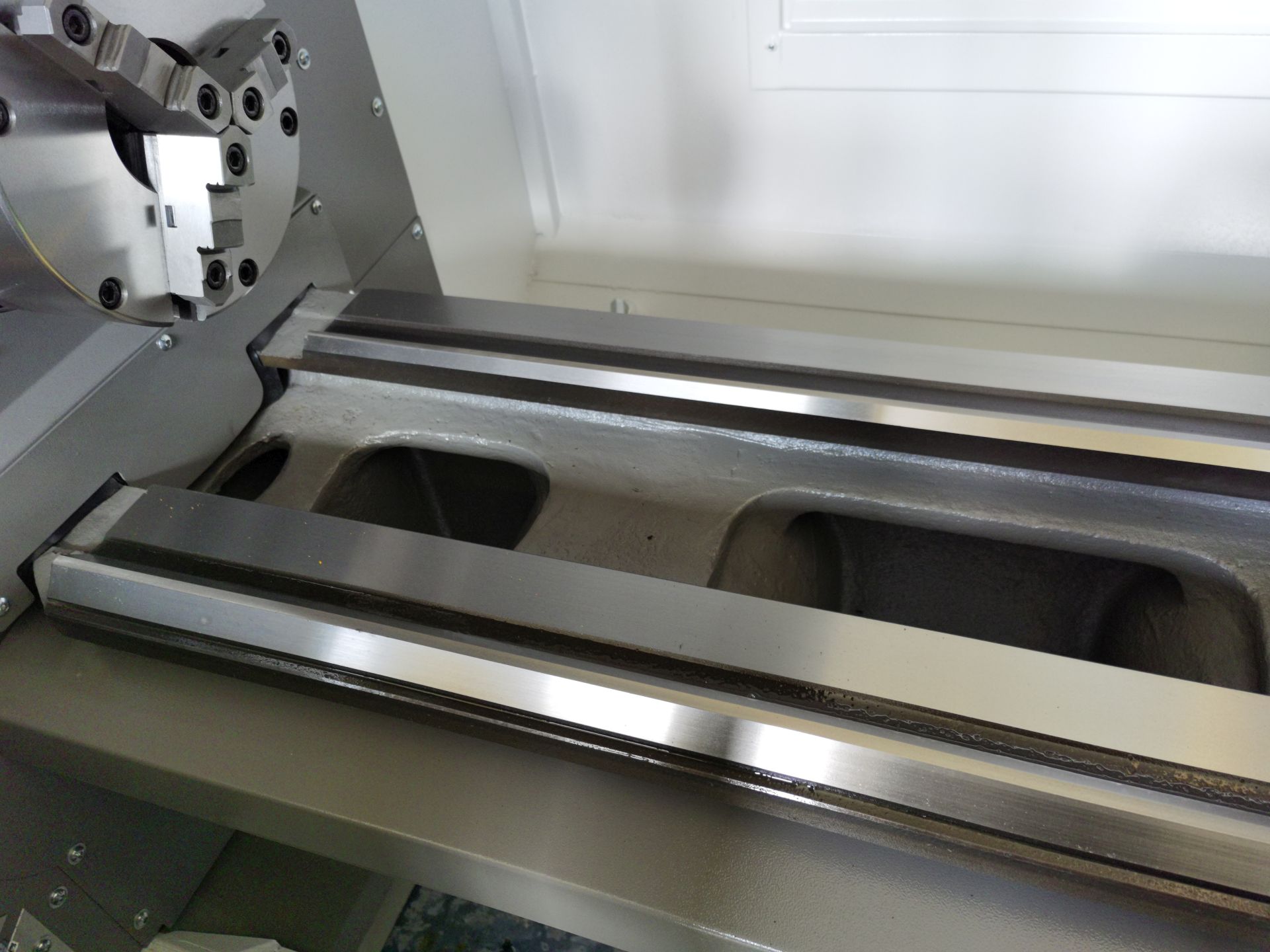

- Bed Guide Rail

- Electrical Distribution Box

- Headstock

| Item | Specification | CAK36 | CAK40 | CAK50 | CAK63 | CAK80 | CAK100 | |||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 65 | 65 | 85 | 85P | 85L | 85P | 85 | 85S | 135 | 135S | 186 | 186S | 85 | 135 | 200 | 285 | 85 | 135 | 135S | 200 | 285 | 85 | 135 | 200 | 285 | ||||||||||||||||||||||||||||

| Control system | FANUC Oi-TF plus system | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | |||||||||||||||||||||||||||||

| GSK 980YA3 system | ◆ | ◆ | ◆ | |||||||||||||||||||||||||||||||||||||||||||||||||

| GSK 980TDi system | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ||||||||||||||||||||||||||||||||||||||||||||

| GSK 988TA system | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||

| Siemens 808AD system | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||

| Siemens 828D system | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ||||||||||||||||||||||||||||||

| NC808Di system | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||

| Protection cover | Semi | ◇ | ◇ | ◇ | ◇ | ◇ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ||||||||||||||||||||||||||||||||||||||

| Full | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◇ | ◇ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | |||||||||||||||||||||||||||||||||

| Tailstock | Manual | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ||||||||||||||||||||||||||

| Hydraulic | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||

| Thinken quill tailstock | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◆ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||

| 3-jaw manual chuck | Φ200 | ◆ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||||||

| Φ250 | ◇ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ||||||||||||||||||||||||||||||||||||||||

| Φ315 | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||

| Φ400 | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||

| Φ500 | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◆ | ◆ | ◆ | ◆ | |||||||||||||||||||||||||||||||||||||||

| Φ800 | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||

| 4-jaw manual chuck | Φ200 | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||||||

| Φ250 | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ||||||||||||||||||||||||||||||||||||||||

| Φ320 | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ||||||||||||||||||||||||||||||||||||||||||||

| Φ400 | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||

| Φ500 | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||

| Φ800 | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||

| Hydraulic chuck | 8″Solid/Hollow | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||||||

| 10″Solid/Hollov | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ||||||||||||||||||||||||||||||||||||||||

| 12″Solid/Hollow | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ||||||||||||||||||||||||||||||||

| 15″Solid/Hollow | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||

| Turret | Vertical 4-position | ◆ | ◆ | ◆ | ◇ | ◆ | ◇ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆170A | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ||||||||||||||||||||||||||

| Horizontal 6-position | ◇ | ◇ | ◇ | ◆ | ◇ | ◆ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||

| Gang tool | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ||||||||||||||||||||||||||||||||||||||||||

| Steady rest | Φ30~Φ80mm(Roller type) | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||||||

| Φ20~Φ125mm(Roller type) | ◇ | ◇ | ◇ | ◇ | ◇ | ◆ | ◆ | |||||||||||||||||||||||||||||||||||||||||||||

| Φ120~Φ190mm(Roller type | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||||

| Φ140~Φ210mm(Roller type) | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||||

| Φ160~Φ350mm(Roller type) | ◇ | ◇ | ◆ | ◆ | ◇ | ◇ | ◇ | ◆ | ◆ | |||||||||||||||||||||||||||||||||||||||||||

| Φ20~Φ170mm(Roller type) | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||

| Φ50~Φ400mm(Roller type) | ◇ | ◇ | ◆ | ◆ | ||||||||||||||||||||||||||||||||||||||||||||||||

| Follow rest (not for horizontal turret) | Φ30~Φ80mm | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||||||

| Φ20~Φ90mm | ◇ | ◇ | ◇ | ◇ | ◇ | ◆ | ◆ | |||||||||||||||||||||||||||||||||||||||||||||

| Φ20~Φ110mm | ◇ | ◇ | ◆ | ◆ | ◇ | ◇ | ◇ | ◆ | ◆ | ◇ | ◇ | ◆ | ◆ | |||||||||||||||||||||||||||||||||||||||

| Boring tool holder | Φ60/Φ80/Φ100/Φ120 | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ||||||||||||||||||||||||||||||||||||||

| Spindle | Single spindle | ◆ | ◆ | ◆ | ◆ | ◆ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||||||||||||||||||

| Manual shift | ◆ | ◆Stepless | ◇Stepless | ◆ | ◇Stepless | ◆ | ◇Stepless | ◆ | ||||||||||||||||||||||||||||||||||||||||||||

| Auto shift | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ||||||||||||||||||||||||||||||||||||

| Chip box | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | |||||||||||||||||||||||||||

| Chi conveyor | Rear chip conveyor | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ||||||||||||||||||||||||||||

| Safety lock | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | ◇ | |||||||||||||||||||||||||||

| ◆ Standard ◇Optional | ||||||||||||||||||||||||||||||||||||||||||||||||||||