Home » Products » MACHINES » Horizontal CNC Lathe » HTC Series HTC125-1500/3000/5000/8000/11000

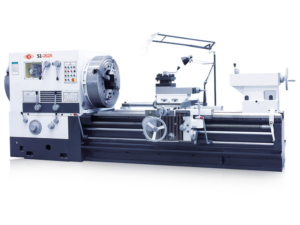

HTC Series HTC125-1500/3000/5000/8000/11000

This series can machine various shaft and disc-type work-pieces.It can also turn thread,circular,arc,cone,inside and outside curved surfaces of rotary parts,and can meet the speed requirements offerrous and non-ferrous metals or high-speed cutting.

This series of machine is designed princpally for the machining of rotary work-pieces with high effciency,in large batches,and with high accuracy in the fields of ship-building, railway locomotive, aerospace,military,metallurgy,etc.

The rigid configuration of the bed,spindle,and tail-stock greatly enhance the overallrigidity of the machine,ensuring stability during heavy cutting.

Home » Products » MACHINES » Horizontal CNC Lathe » HTC Series HTC125-1500/3000/5000/8000/11000

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

If you can't find what you're looking for

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Check out our FAQ page for answers to common questions

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Check out our FAQ page for answers to common questions

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Still haven't found what you're looking for your questions

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Check out our FAQ section for more information on how we can help

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Still haven't found what you're looking for your questions

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

If you can't find what you're looking for

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Still haven't found what you're looking for your questions

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

If you can't find what you're looking for

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Check out our FAQ page for answers to common questions

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

If you can't find what you're looking for

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Still haven't found what you're looking for your questions

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

If you can't find what you're looking for

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Still haven't found what you're looking for your questions

I am item content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Export to Excel

| HTC125-1500/3000/5000/8000/11000 | ||||

|---|---|---|---|---|

| Item | Unit | Specification | ||

| Max. Swing Over Bed | mm | 1250 | ||

| Max. Cutting Length | mm | 1250/2850/4850/7850 | ||

| Max. Cutting Diameter | mm | 1250 | ||

| Max. swing over slide | mm | 820 | ||

| Distance of bed guideway | mm | 755 | ||

| Spindle nose | A2-15 | |||

| Spindle Front Hole Size | mm | 140 | ||

| Dia. of spindle hole | mm | 130 | ||

| Spindle | ||||

| Spindle Speed Range | r/min | 5~500 | ||

| Max. spindle torque | Nm | 8000 | ||

| Gears of Spindle Speeds | Hydraulic three gears, infinitely variable speed within each gear | |||

| Main Motor Output Power | kW | 22 | ||

| Chuck Diameter/Type | mm | Φ1000/Manual Four-Jaw | ||

| Maximum Cutting Force | kN | 25 | ||

| X-Axis Rapid Traverse Speed | m/min | 6 | ||

| Z-Axis Rapid Traverse Speed | m/min | 6 | ||

| X-Axis Travel | mm | 650 | ||

| Z-Axis Travel (Quill Distance) | mm | 1250/2850/4850/7850/10850 | ||

| Tailstock | ||||

| Quill diameter | mm | 160 | ||

| Quill travel | mm | 300 | ||

| Tailstock taper | Morse | 6# | ||

| Maximum Load | ||||

| Disk workpiece | kg | 1000 | ||

| Shaft workpiece | kg | 6000 | ||

| Others | ||||

| Distance to Bed | mm | 625 | ||

| Distance to Ground | mm | 1275 | ||

| Weight | kg | 13000/15000/18000/22000/30000 | ||

| Overall dimensions (LxWxH) | mm | 5346/6650/8846/*/*x 2725 x 2450 | ||

| Power capacity | KVA | 51 | ||

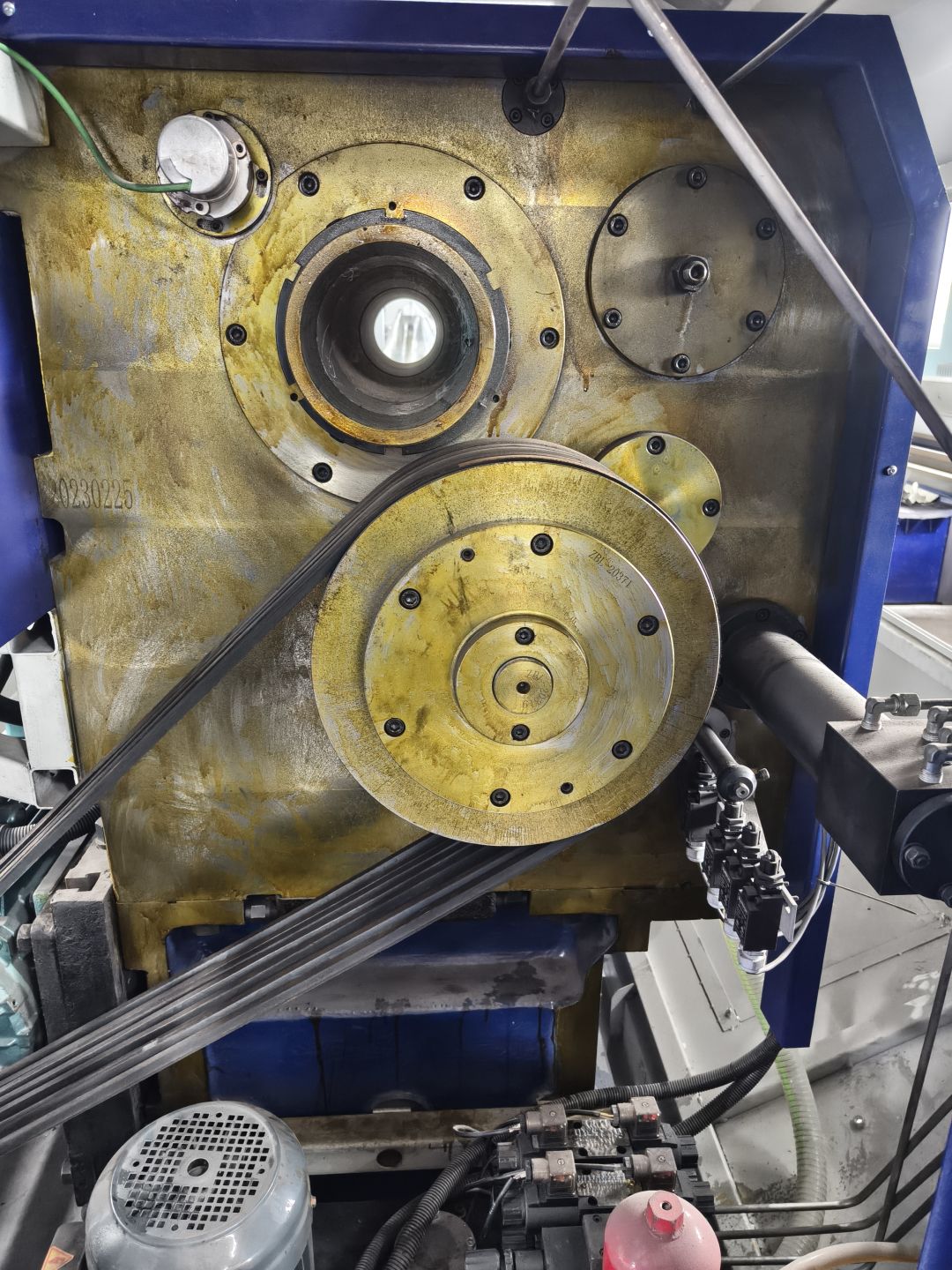

- Headstock

- Chuck

- Steady rest

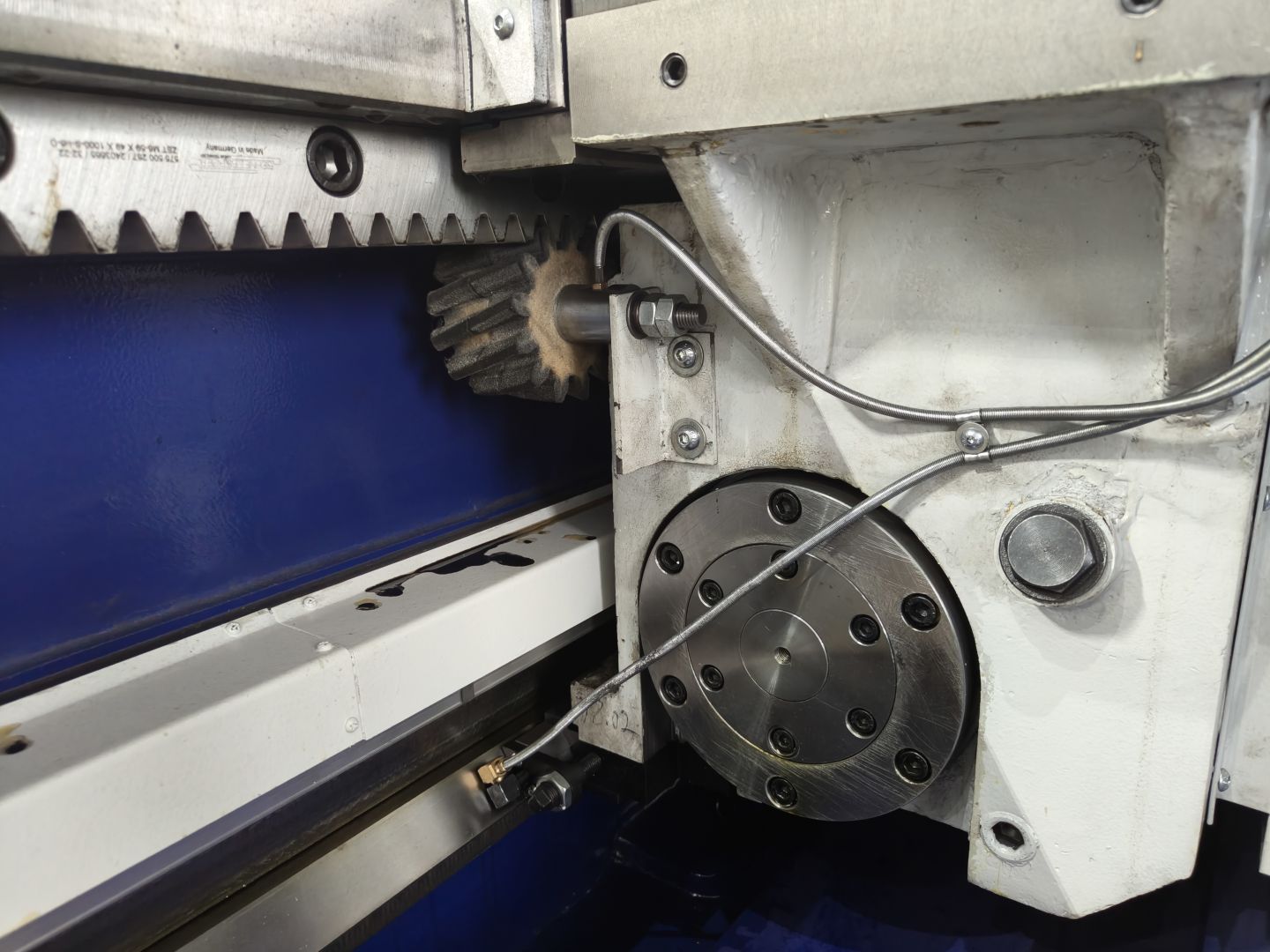

- Saddle& slide

- Tailstock

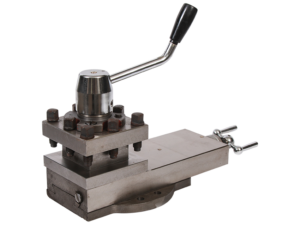

- Turret

- Bed

- Operation panel

- Linear Guide Systems with Integral Rack Drive

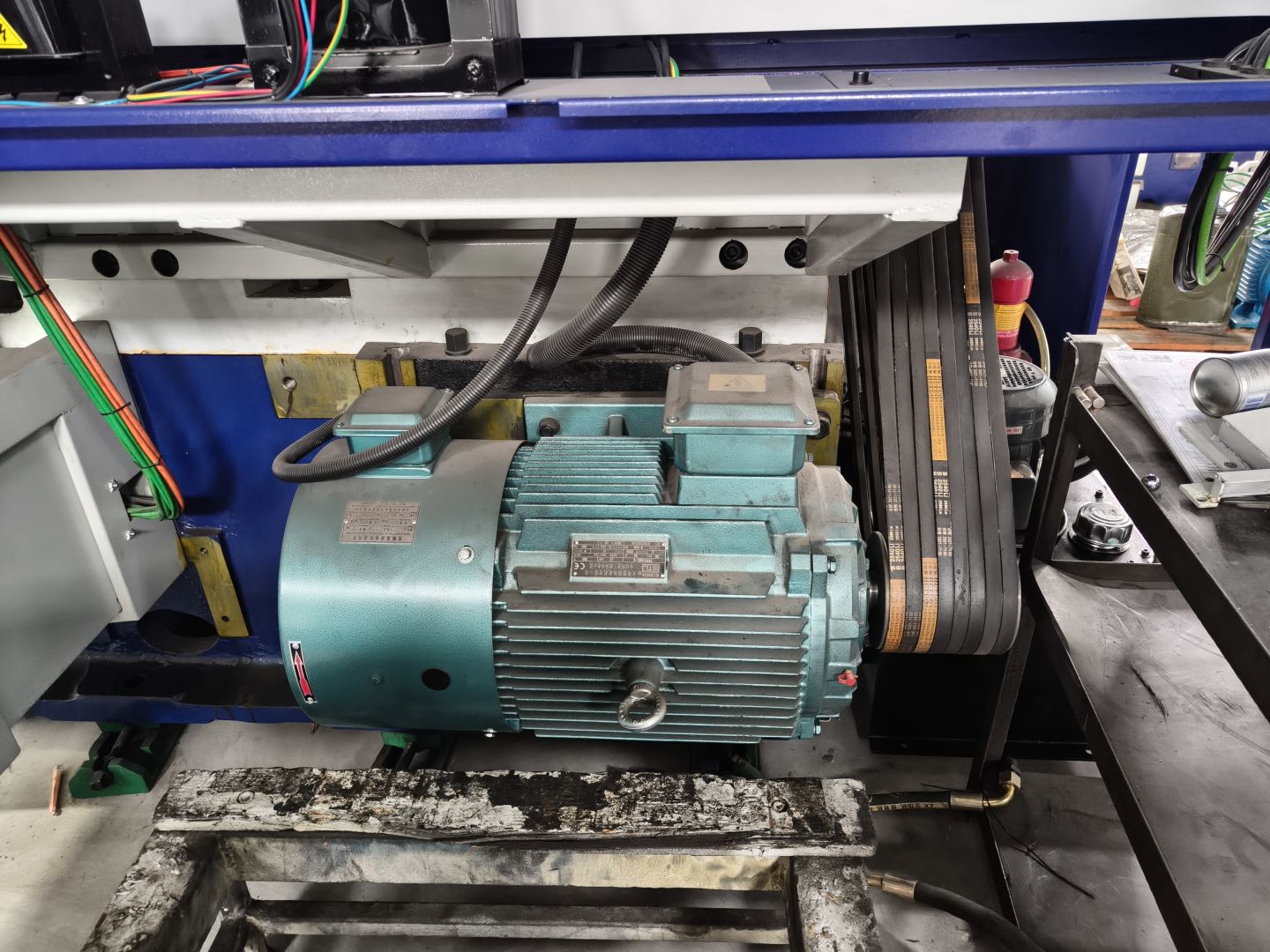

- Main Motor

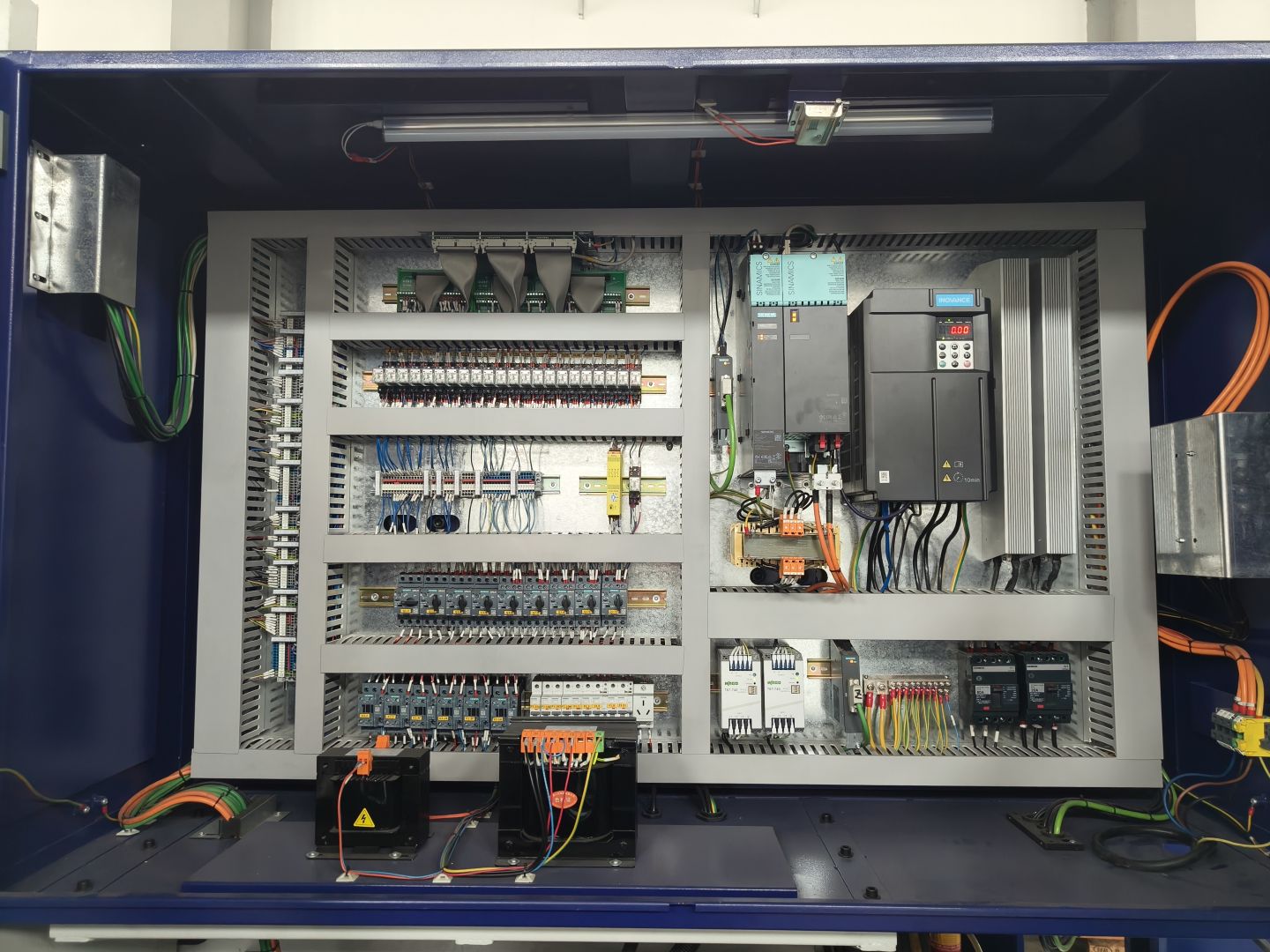

- Distribution Box

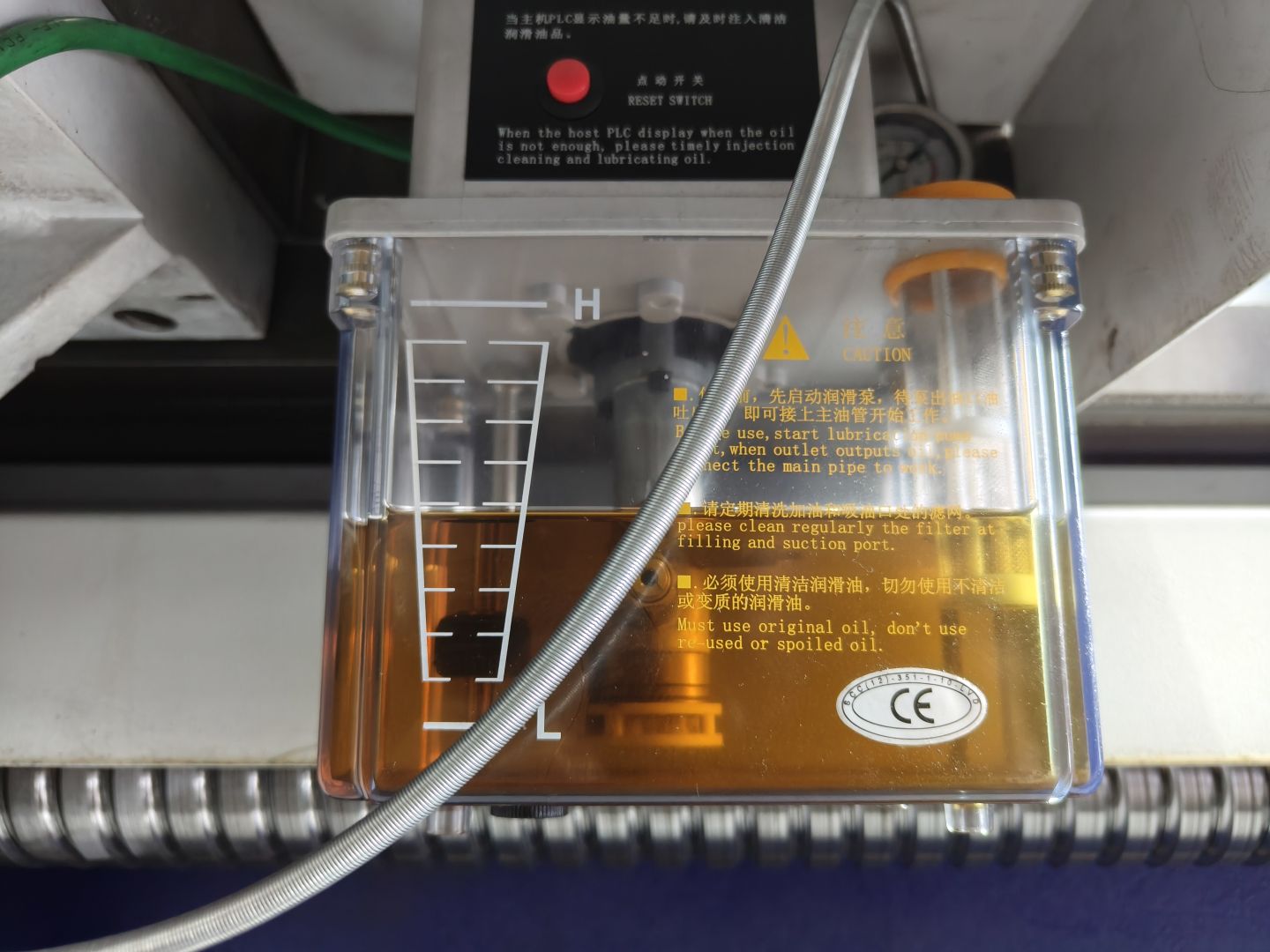

- Lubrication Station

Resources & Downloads

SMTCL HTC Series Heavy Duty LARGE-TYPE Horizontal CNC Lathe Machine Catalog

File size: 3.19 MB

Created: 13-07-2024

Updated: 13-07-2024

Hits: 183

SMTCL Comprehensive Catalogue

File size: 5.59 MB

Created: 15-06-2024

Updated: 15-06-2024

Hits: 668

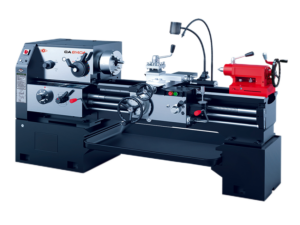

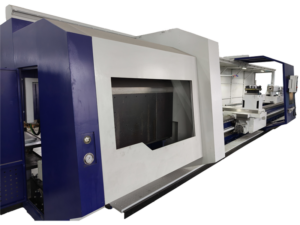

Recommended Related Products

If needed, please contact us for further selection

Recommended Related Products

Load More

Need help finding a machine?

We will gladly assist you in making the right decision to achieve your business goals

Get a free Consultation