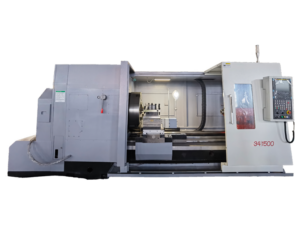

Home » Products » MACHINES » Horizontal CNC Lathe » T5 Series T5-500Q T5-1000Q T5-500S T5-1000S

T5 Series T5-500Q T5-1000Q T5-500S T5-1000S

Home » Products » MACHINES » Horizontal CNC Lathe » T5 Series T5-500Q T5-1000Q T5-500S T5-1000S

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| Technical parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item | Unit | T5.1-100Q | T5.1-500Q | T5.2-500Q | T5.2-1000Q | T5.2-500S | T5.2-1000S | |

| Max. cutting dia. | mm | Φ160 | Φ280 | Φ360 | Φ360 | Φ380 | Φ380 | |

| Max. cutting length | mm | 160 | 500 | 500 | 1000 | 500 | 1000 | |

| Max. swing over bed | mm | Φ420 | Φ420 | Φ560 | Φ560 | Φ560 | Φ560 | |

| Max. swing over slide | mm | Φ160 | Φ280 | Φ350 | Φ350 | Φ400 | Φ400 | |

| Spindle | ||||||||

| Spindle nose | – | A2-5 | A2-6 | A2-6 | A2-6 | A2-8 | A2-8 | |

| Front bearing dia. | mm | 90 | 100 | 100 | 100 | 120 | 120 | |

| Spindle taper and hole size | – | 1:20;Φ62 | 1:20;Φ70 | 1:20;Φ70 | 1:20;Φ70 | 1:20;Φ90 | 1:20;Φ90 | |

| Dia. of spindle hole | mm | Φ56 | Φ65 | Φ65 | Φ65 | Φ80 | Φ80 | |

| Max. dia. of bar | mm | Φ44 | Φ50 | Φ50 | Φ50 | Φ65 | Φ65 | |

| Chuck size | inch | 6 | 8 | 8 | 8 | 10 | 10 | |

| Spindle speed | r/min | 5000 | 4500 | 4500 | 4500 | 4000 | 4000 | |

| Spindle torque | N-m | 35(2000r/min) | 110(769r/min) | 136(769r/min) | 136(769r/min) | 180(769r/min) | 180(769r/min) | |

| Max. spindle torque | N-m | 70(1500r/min) | 180(576r/min) | 245(576r/min) | 245(576r/min) | 300(576r/min) | 300(576r/min) | |

| Main motor output power continuous/30min | kW | 7.5/11 | 9/11 | 11/15 | 11/15 | 15/18.5 | 15/18.5 | |

| X/Z axis | ||||||||

| X/Z rapid traverse | m/min | 30 | 30 | 30 | 30 | 20 | 20 | |

| X axis travel | mm | 145 | 160 | 200 | 200 | 200 | 200 | |

| Z axis travel | mm | 205 | 560 | 560 | 1050 | 560 | 1025 | |

| Tailstock | ||||||||

| Tailstock travel | mm | – | 300 | 500 | 950 | 350 | 770 | |

| Quill travel | mm | – | 100 | – | 100 | 100 | – | |

| Quill diameter | mm | – | Φ80 | – | – | Φ100 | Φ100 | |

| Tailstock taper | Morse | – | MT-5 | MT-5 | MT-5 | MT-4 | MT-4 | |

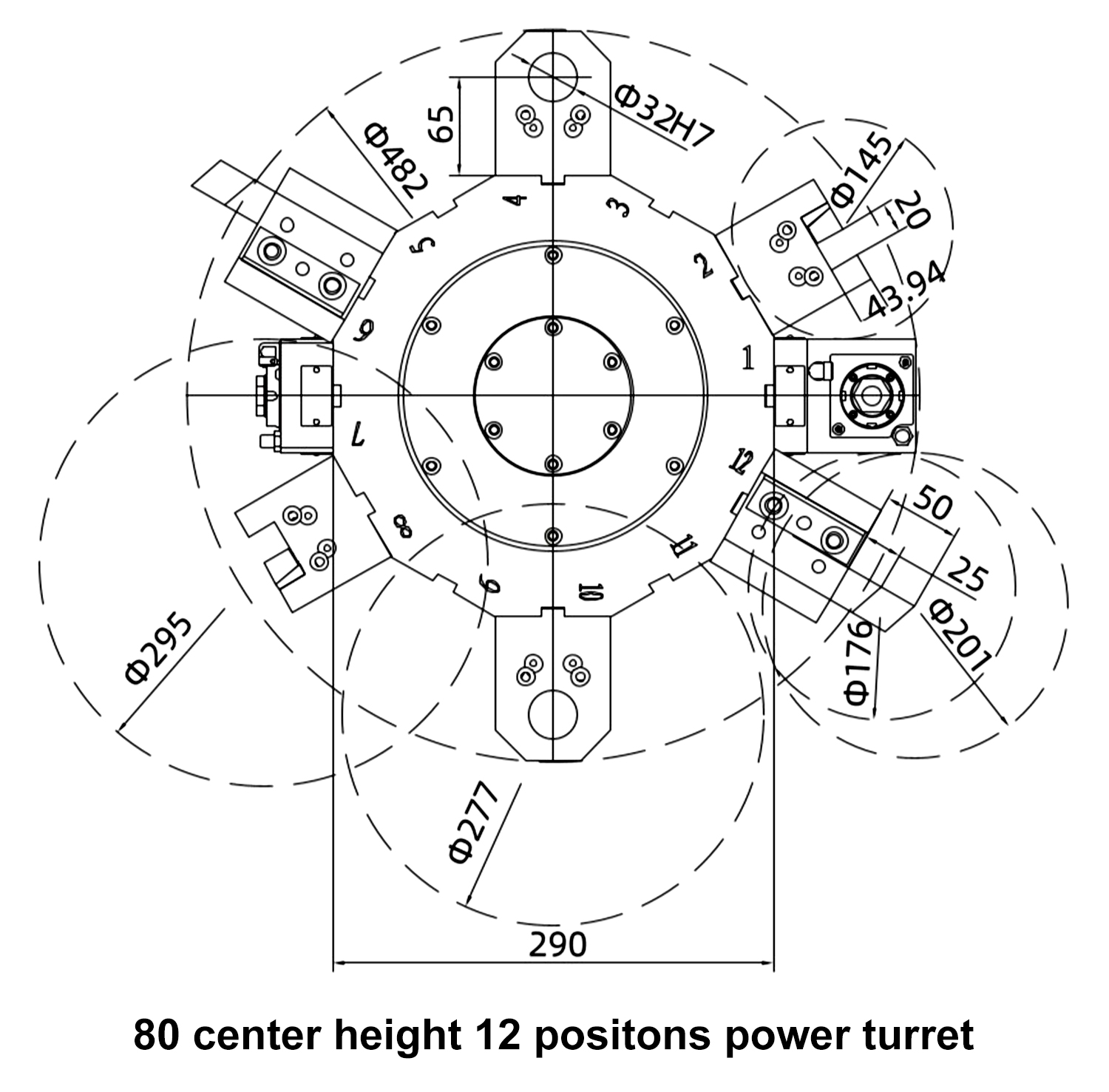

| Turret | ||||||||

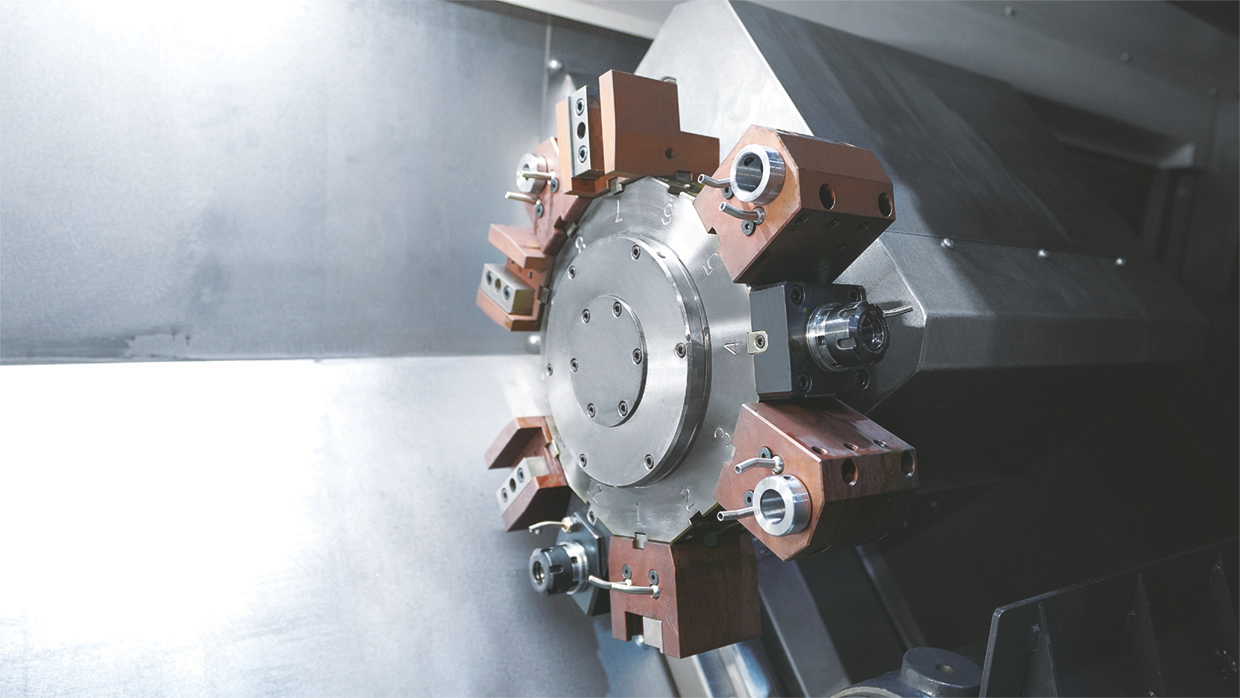

| Turret type | – | Horizontal 8 positions servo turret | Horizontal 8 positions servo turret | Horizontal 8 positions servo turret | Horizontal 8 positions servo turret | Horizontal 8 positions servo turret | Horizontal 8 positions servo turret | |

| Center height | mm | 63 | 80 | 80 | 80 | 100 | 100 | |

| Rotary repeat positioning | Sec. | ±1.6 | ±1.6 | ±1.6 | ±1.6 | ±1.6 | ±1.6 | |

| Nearby tooling | – | Yes | Yes | Yes | Yes | Yes | Yes | |

| Others | ||||||||

| Distance between spindle center and floor | mm | 926 | 936 | 1015 | 1015 | 1015 | 1015 | |

| Weight | kg | 2600 | 3500 | 4200 | 4750 | 4300 | 5000 | |

| Power capacity | kVA | 23 | 23 | 27 | 27 | 42 | 42 | |

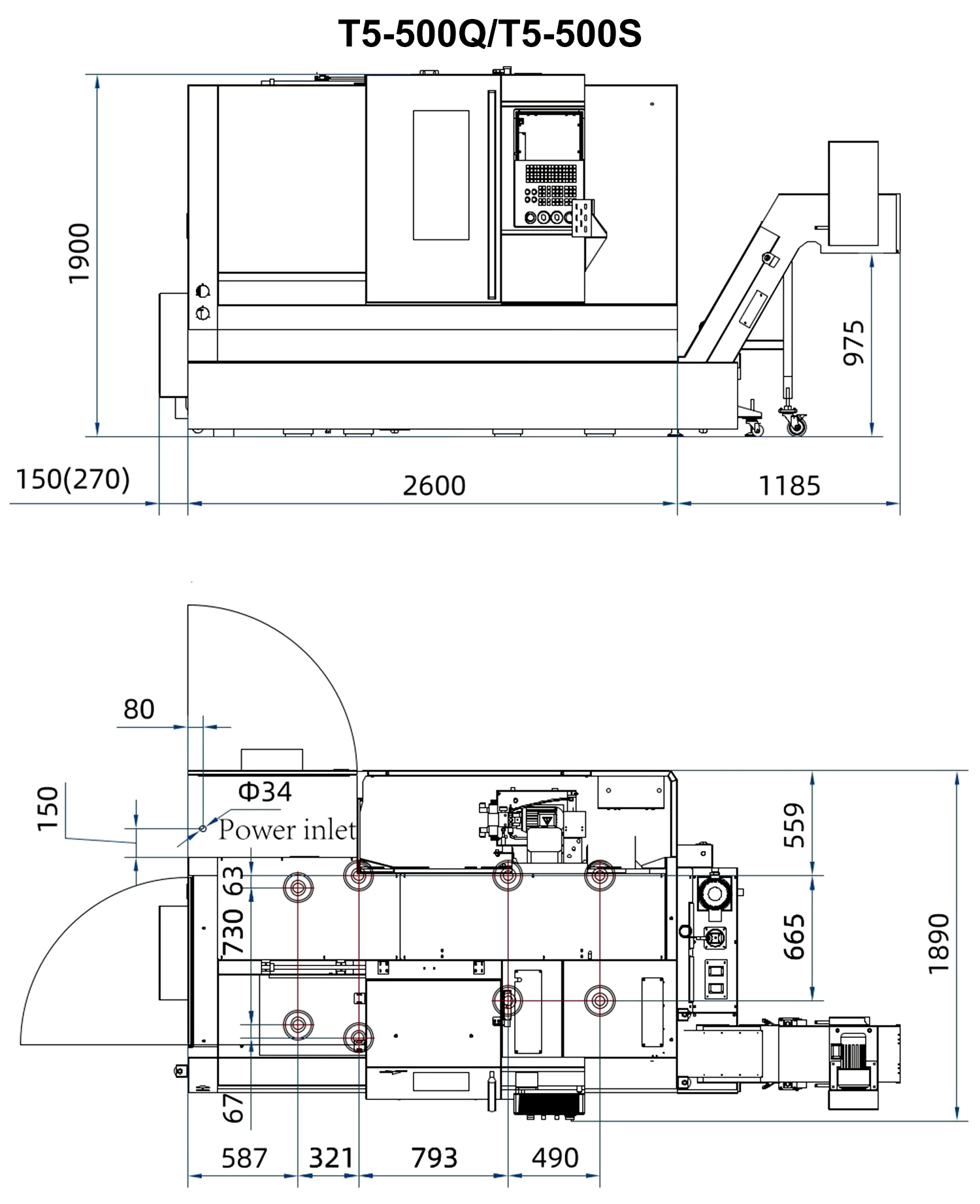

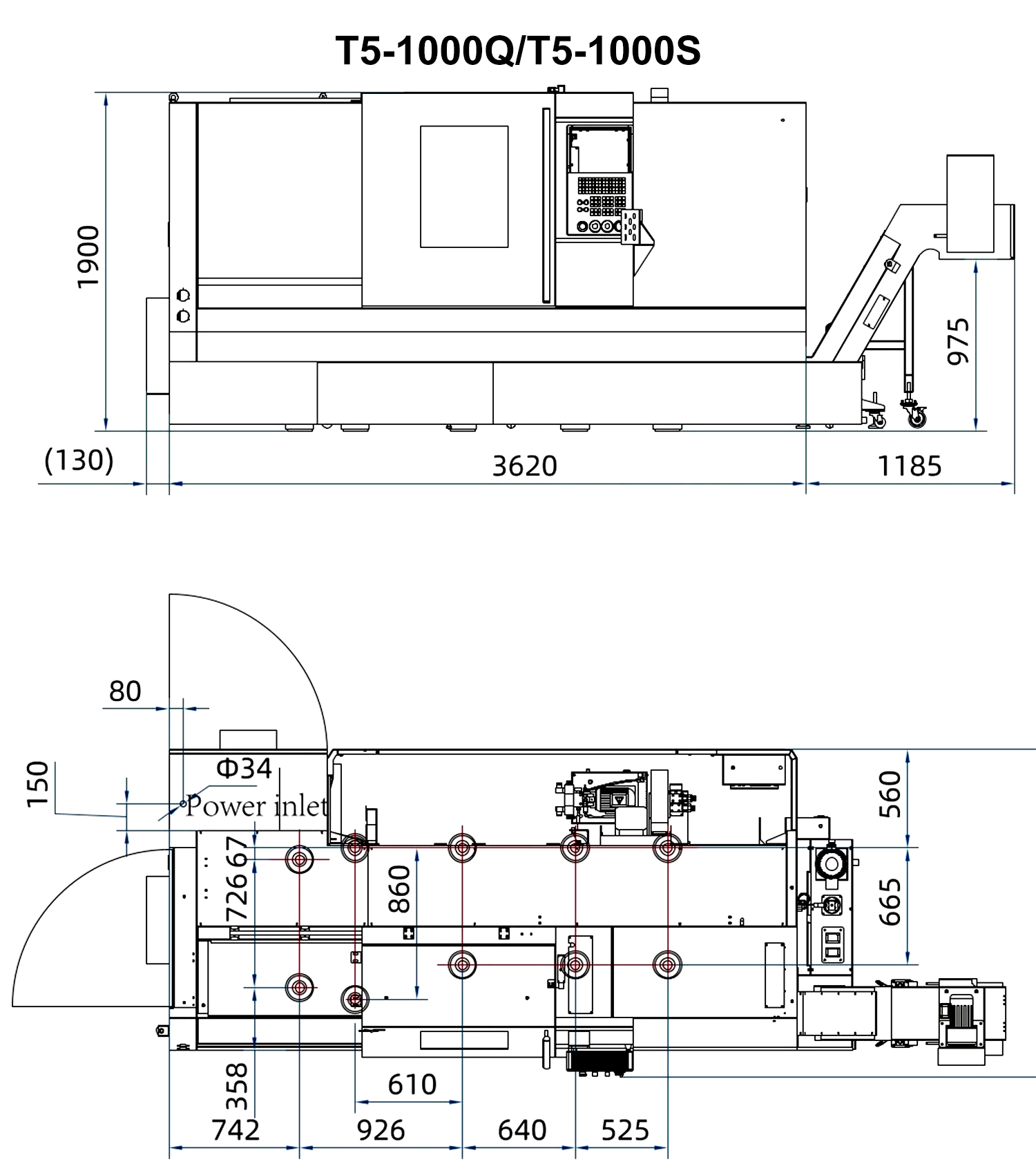

| Overall dimensions (LxWxH) | mm | 1750x1650x1650 | 2300x1680x1650 | 2750x1890x1900 | 3620x1890x1900 | 2870x1890x1900 | 3750x1890x1900 | |

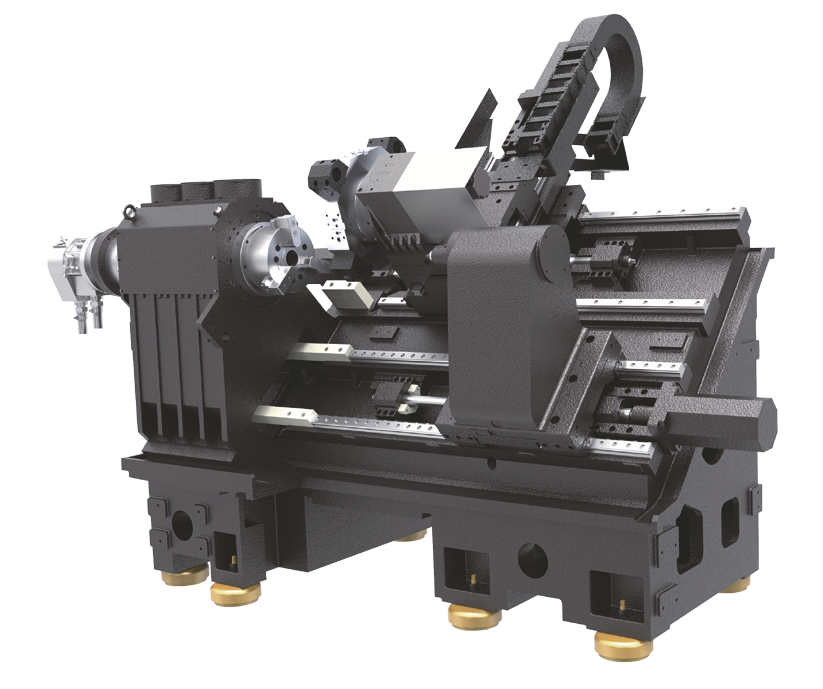

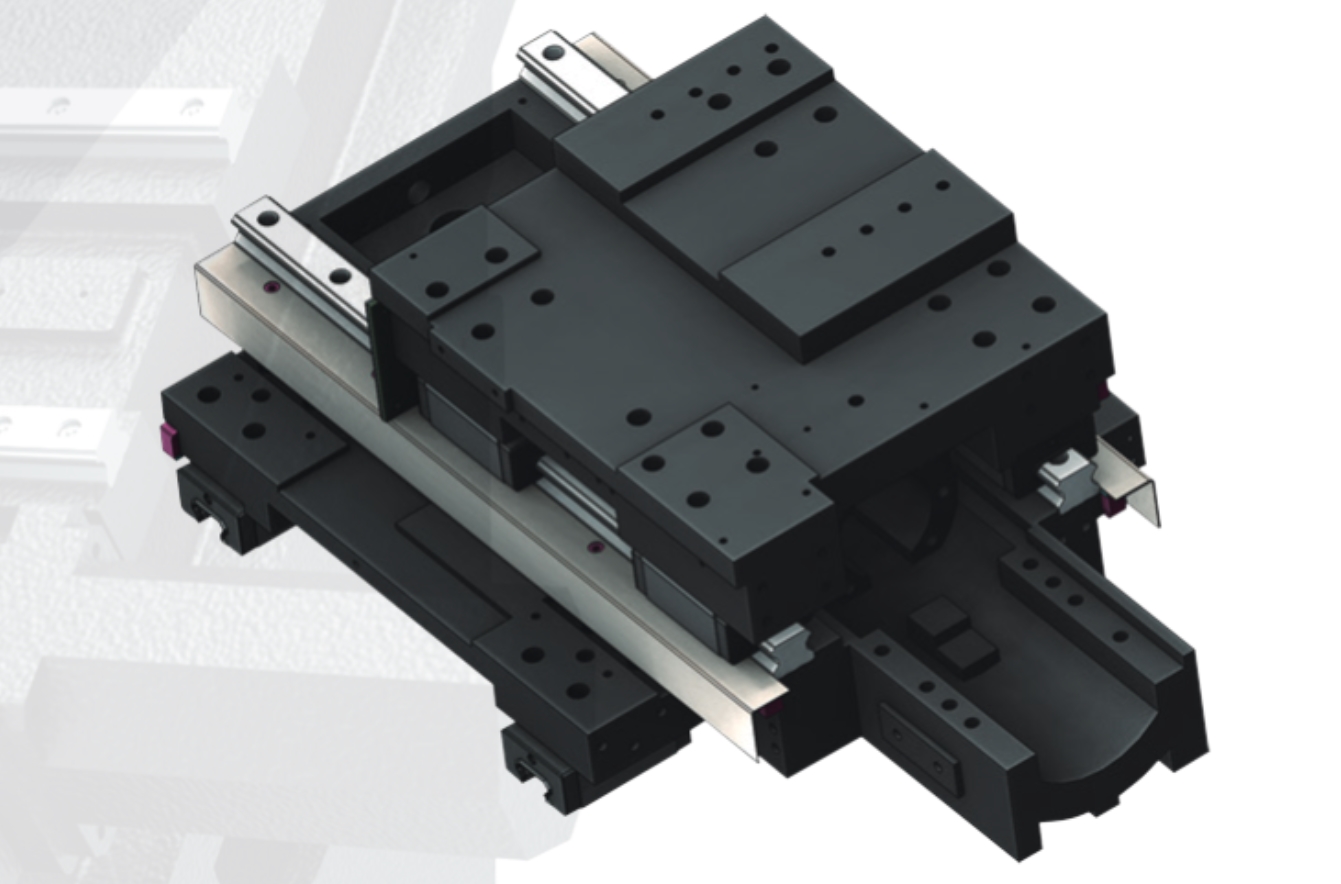

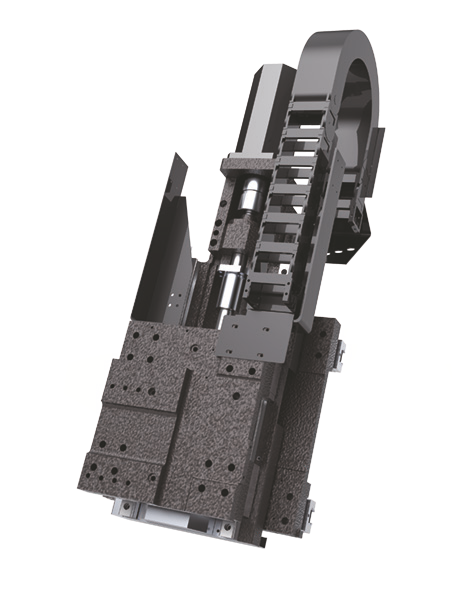

Main body T5-500/1000Q

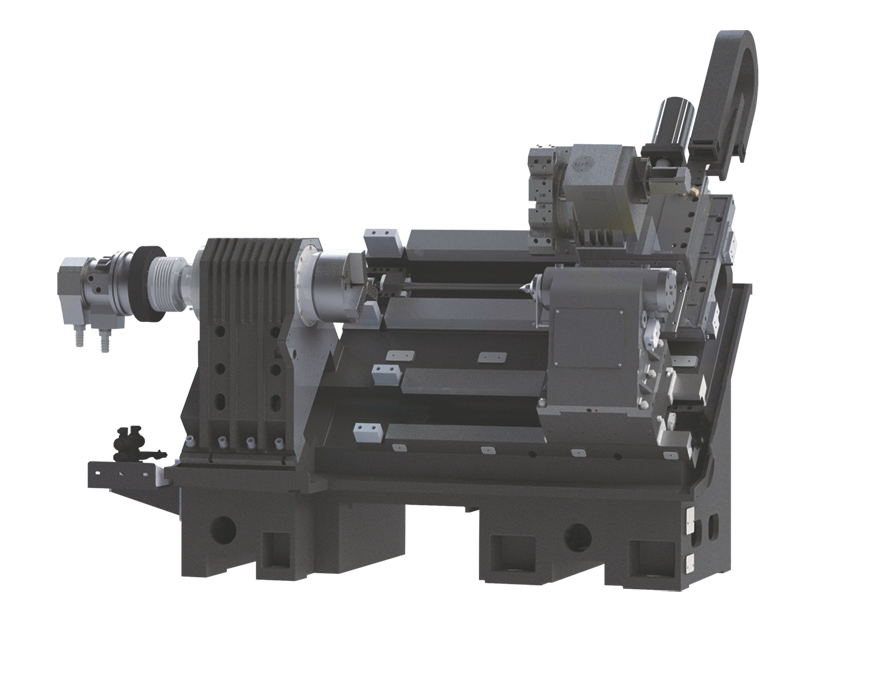

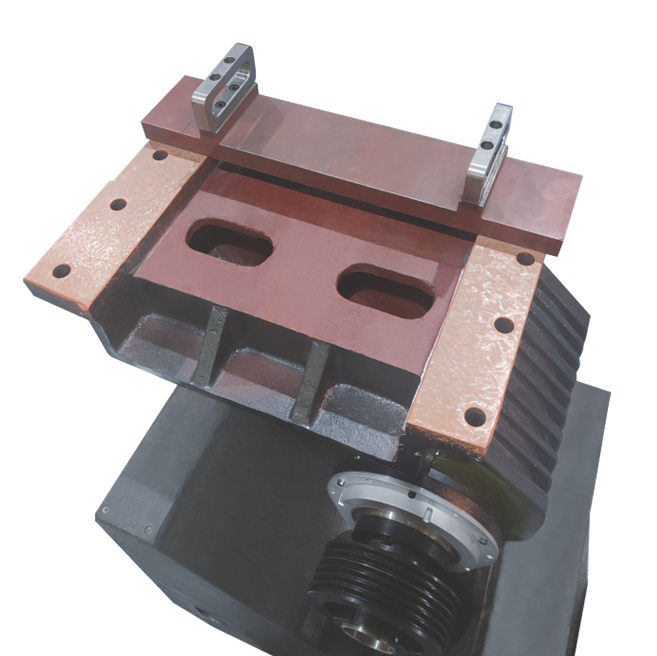

Main body T5-500/1000S

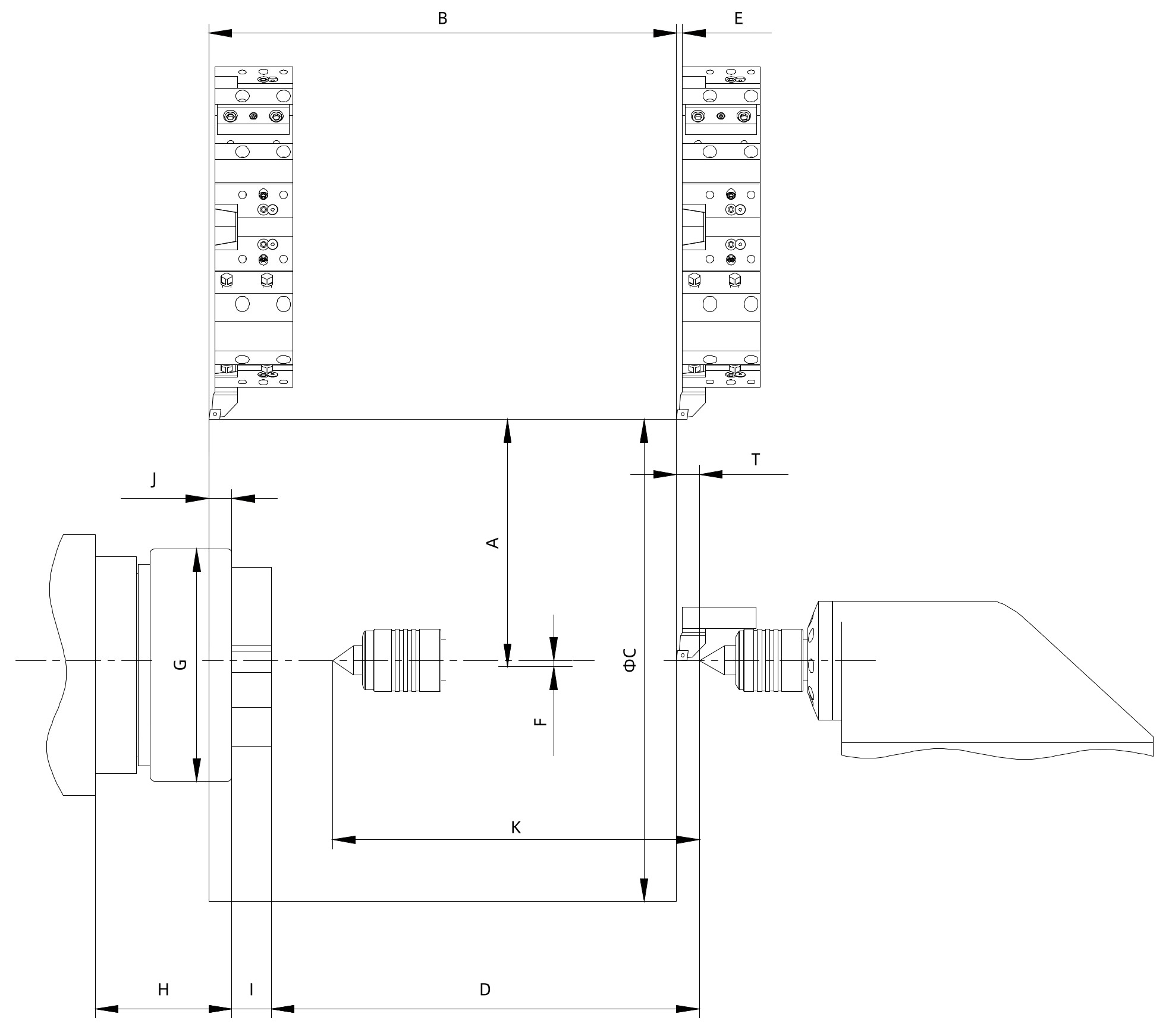

Machine layout

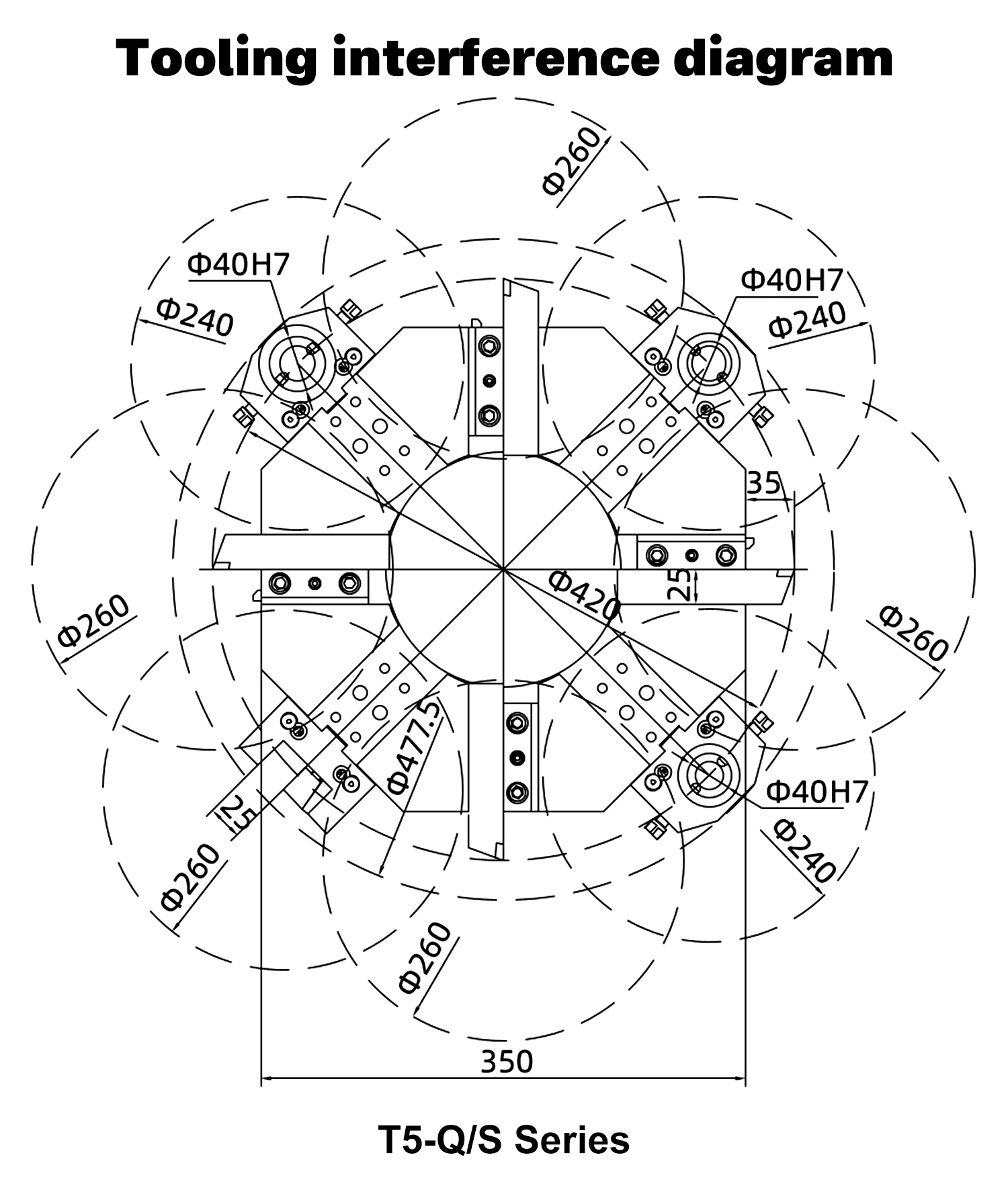

Tooling interference diagram

Machining range

| Model | T5.1-100Q | T5.1-500Q | T5-500Q | T5-1000Q | T5-500S | T5-1000S |

|---|---|---|---|---|---|---|

| Unit | mm | mm | mm | mm | mm | mm |

| A | 145 | 160 | 200 | 200 | 200 | 200 |

| B | 205 | 560 | 560 | 1050 | 560 | 1025 |

| C | 280 | 310 | 390 | 390 | 390 | 390 |

| D | 163 | 519 | 510 | 1010 | 510 | 970 |

| E | 7 | 7 | 7 | 7 | 7 | 7 |

| F | 5 | 5 | 5 | 5 | 5 | 5 |

| G | 169 | 210 | 210 | 210 | 254 | 254 |

| H | 163 | 140 | 140 | 140 | 158 | 158 |

| I | 39.5 | 39.5 | 39.5 | 43 | 43 | |

| J | 5 | 2 | 5 | 5 | 5 | 5 |

| K | – | 400 | 500 | 950 | 450 | 870 |

| T | – | 0 | 0 | 0 | 0 | 0 |

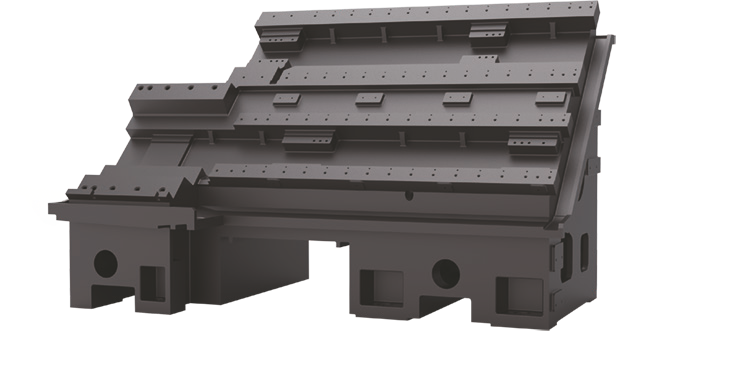

- High rigidity body

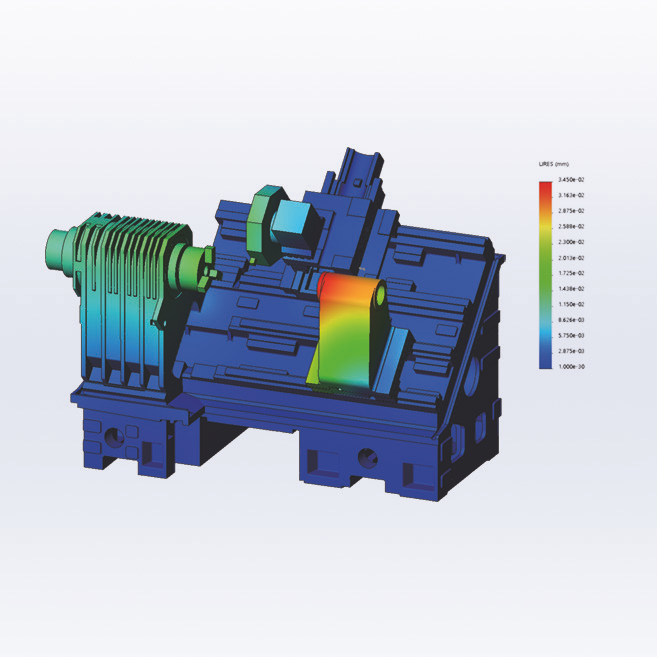

- Whole machine FEA analyse

- High regidity spindle

- Anti-bend body

- Second spindle tailstock

- Rigidity cutting test

- Double support pre-tension structure

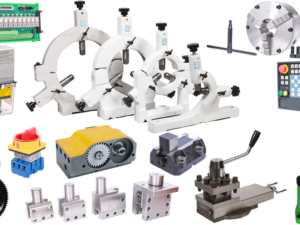

- R&D of patented tooling

- High precision ballscrew

- Assemble quantitative techonolgy

- Rapid traverse speed: 30m/min

- Effective servo turret

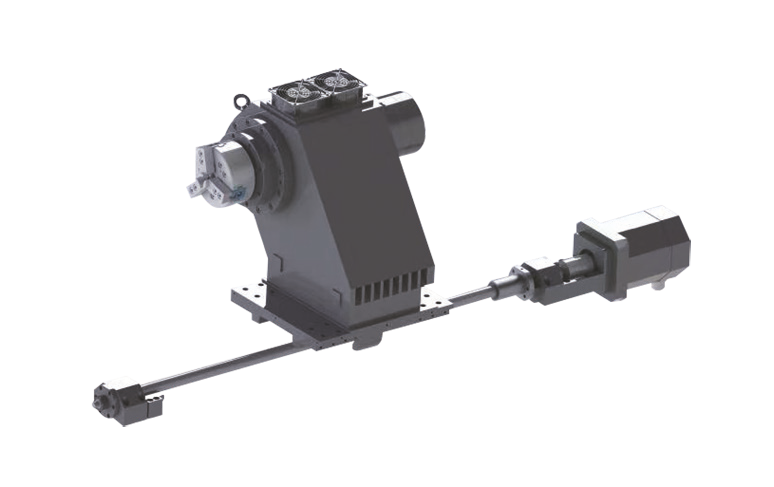

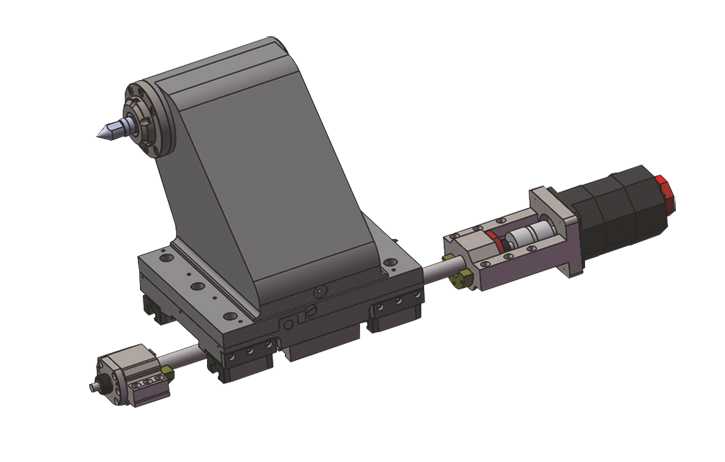

- Split type servo tailstock

- Coolant through turret as option

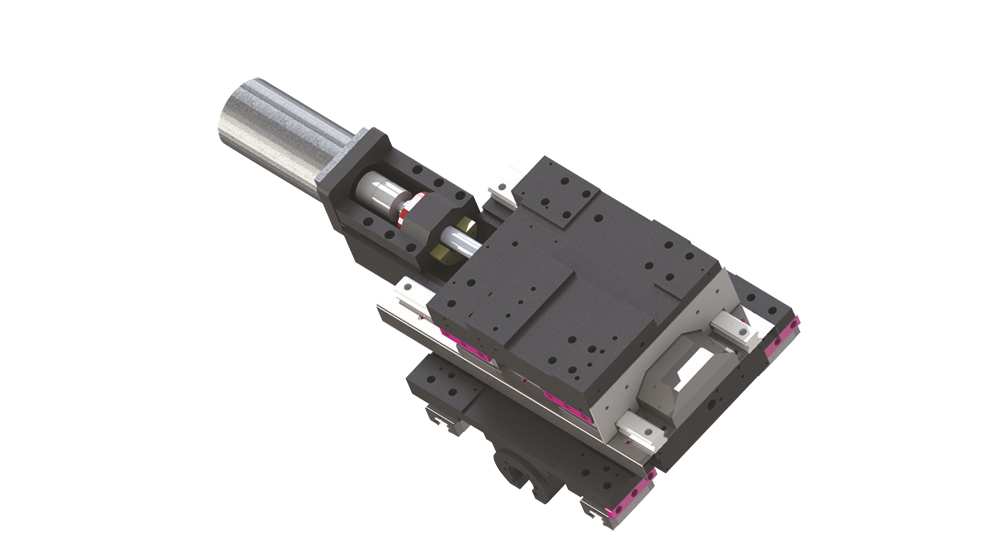

- Sub-spindle module

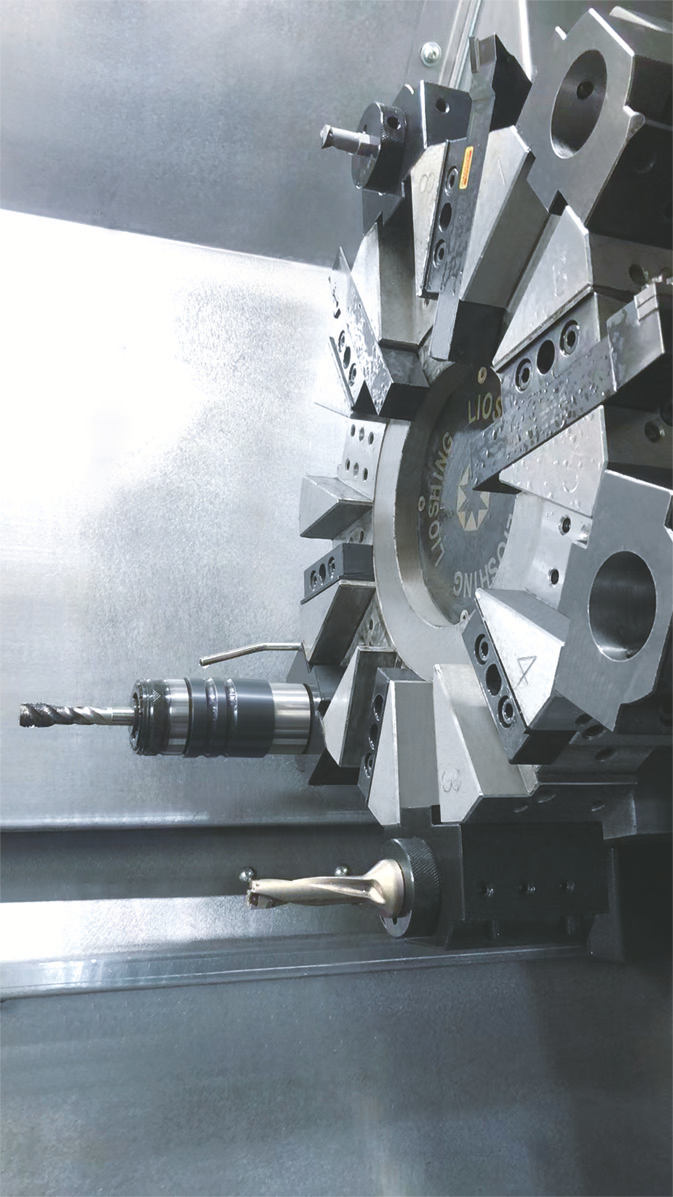

- Servo powered turret

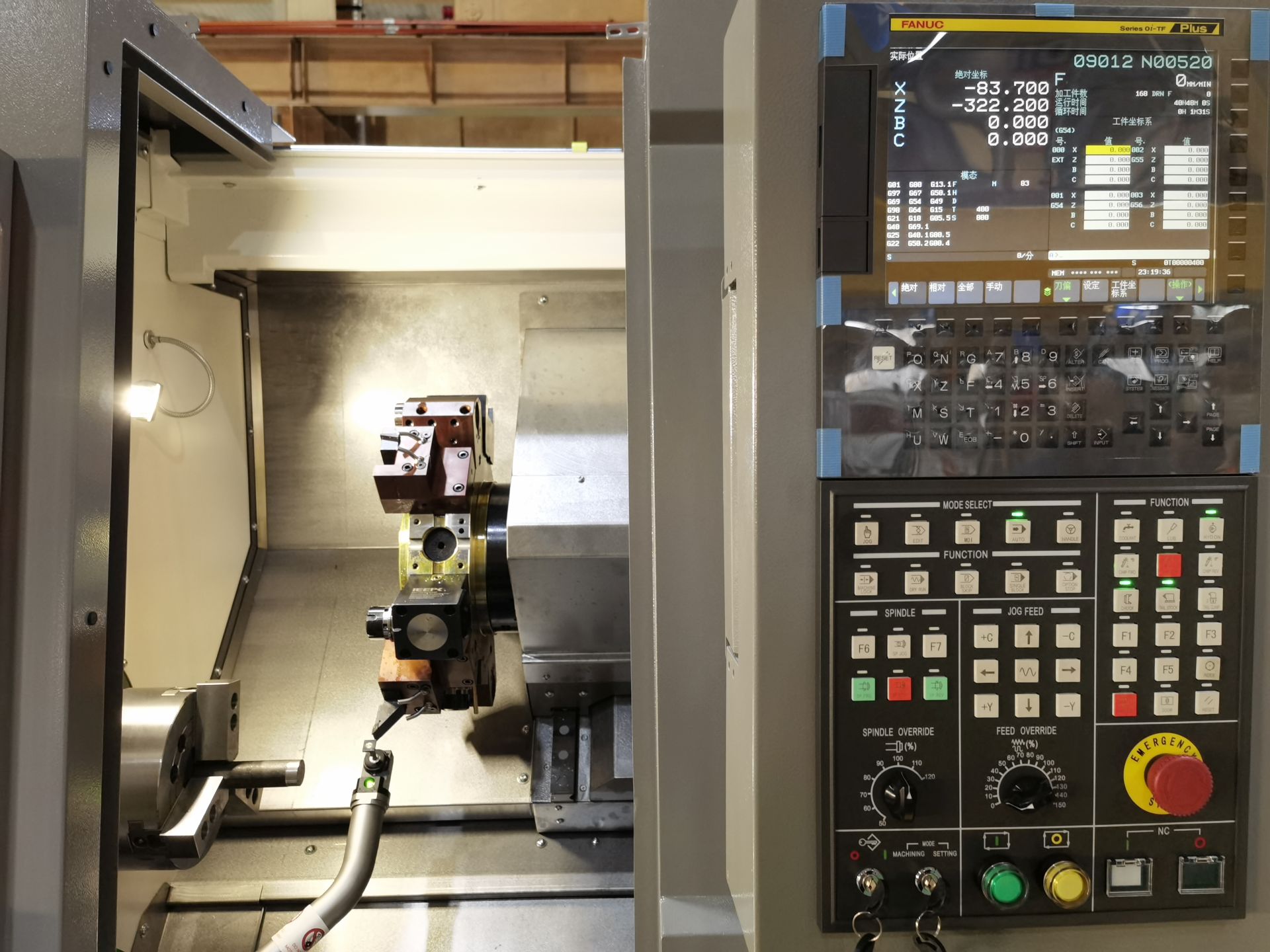

- Customizable CNC Operating System

- Distribution Box

Overall body with high rigidity,U shape structure in the body to giving enough support to important parts, double scretch in the headstock surface to improve cutting regidity.

Optimize machine structure and improve regidity, anti-vibration by FEA analyse and topology design, also get can mass production for swing type workpiece.

Big gap sleeve type spindle unit has double line bearings and ball bearings support to enhance the spindle’s regidity and torque, can get excellent heavy cutting result.

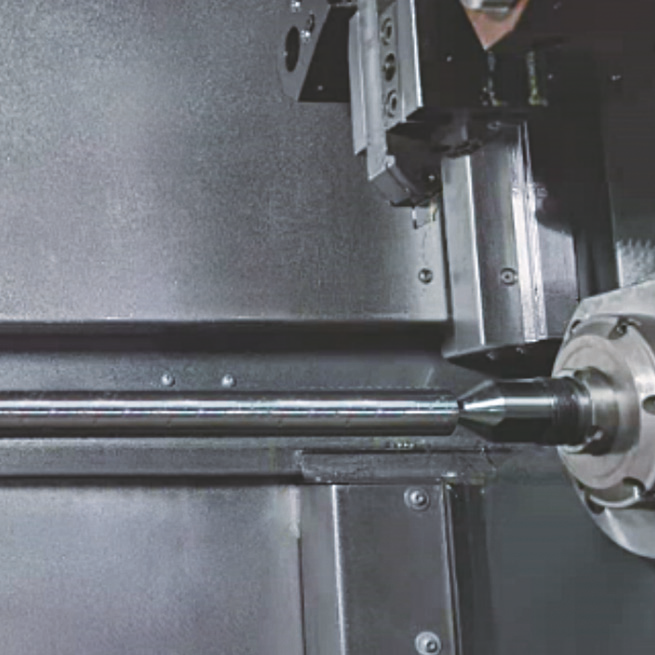

Dia. φ70mm batch test: Material: 45# Shaft workpiece cutting length/dia. more than 1:20 Material: 40Cr Shaft workpiece cutting length/dia. more than 1:25

Adopts high quality imported C3 class ballscrew and H class guideway driven by servo motor to get running precision.

Use torque wrench,tensiometer,dynamic balance instrument and laser interferometer for key parts to ensure the asseble result.

Coupling and ballscrew contact by servo motor driven without gap.X/Z axis both installed import linear guideway to ensure the high rigidity,excellent dynamic ability and precision, improve running speed and production efficiency.

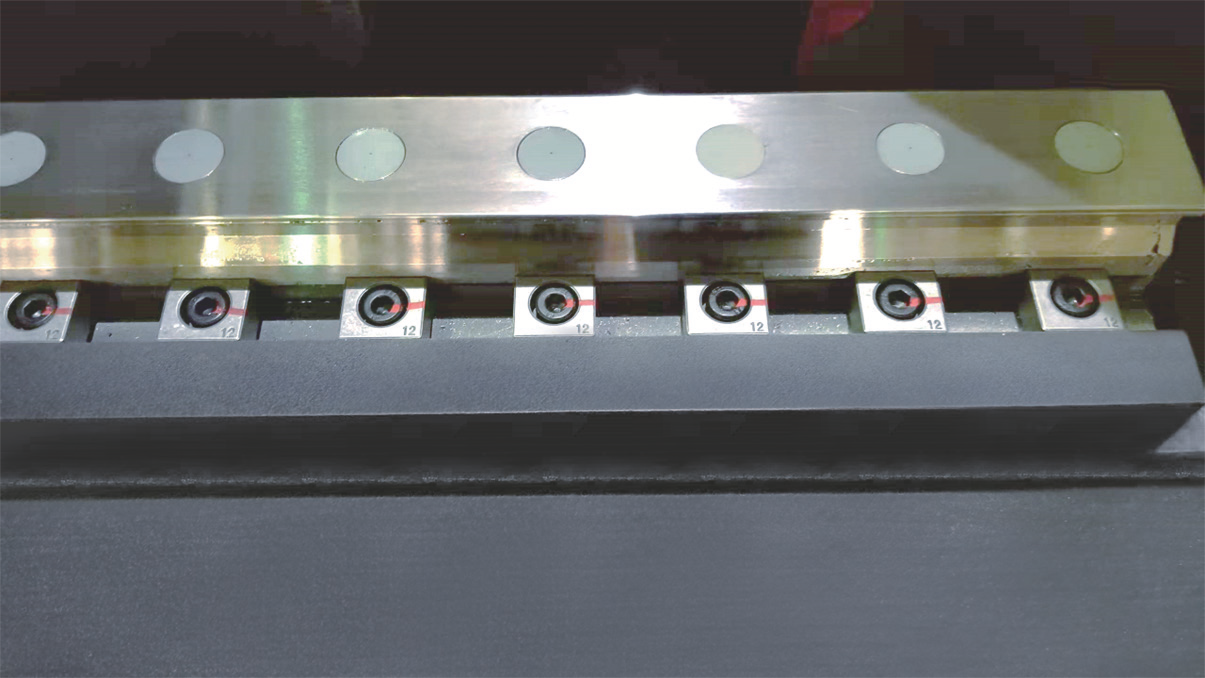

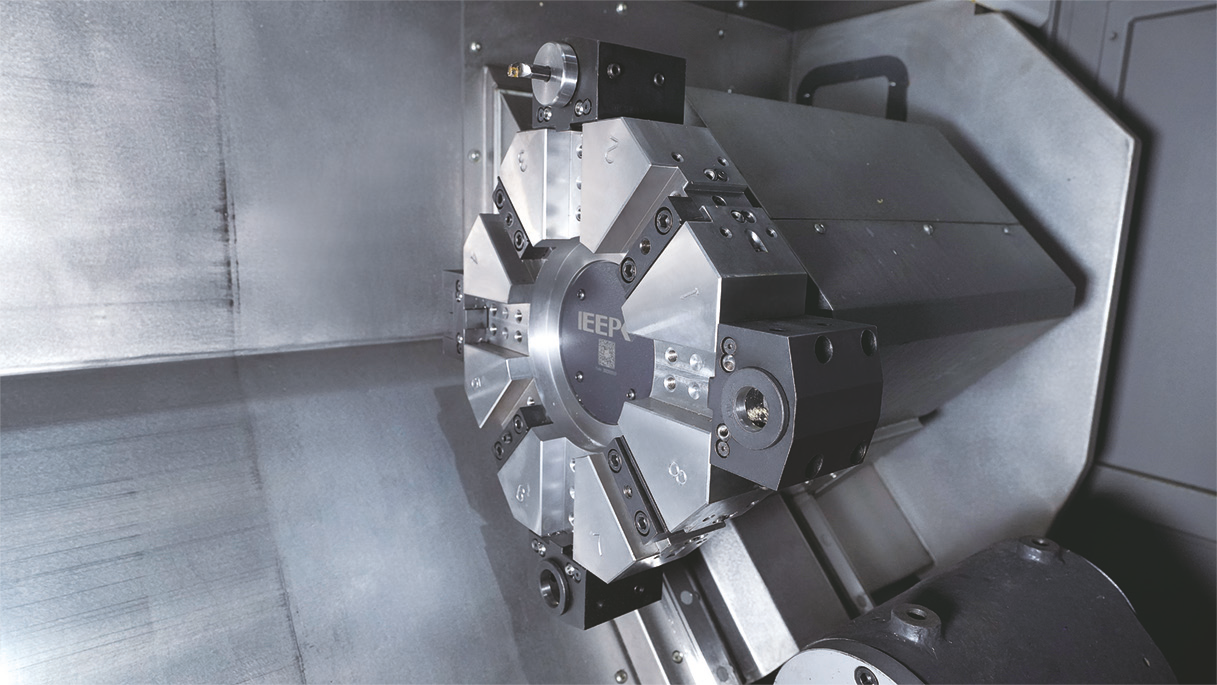

Servo turret can continously rotate and be fast, biodirection, espeically suitable for frequent tool change.Turret rotaty driven by reduction motor,locked well in the right location. The internal design is simple, not easy to brake down.

Tailstock driven by servo way, adjust tailstock moving speed and jacking force accoridng to workpiece demand to get tailstock fast contact without touch.UP-down positon seperate tailstock easy to adjust and improve maintain efficiency.