Home » Products » MACHINES » Vertical Machining Center » VMC Q Series VMC850Q VMC1000Q VMC1100Q

VMC Q Series VMC850Q VMC1000Q VMC1100Q

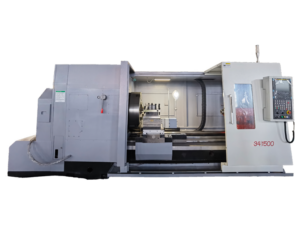

VMC-Q series machine tools are the new generation general vertical machining center through independent R&D for industrial areas such as general machinery, automobile, and so on.

Through professional design and analysis software for scientific and reasonable analysis and optimization, as well as advanced manufacturing and testing technology for verification and improvement, the equipment has good cutting performance, which can satisfy the requirements of drilling and milling of various parts and provide the customers with the best processing experience.

◆ Error compensation technology

Safety, environment friendly, efficient productivity

Home » Products » MACHINES » Vertical Machining Center » VMC Q Series VMC850Q VMC1000Q VMC1100Q

Contact

Wide Product Portfolio

We supply a diverse range of conventional and CNC metalworking machines loaded with features

Professional Consultation

Trusted consultation and in house demonstrations to provide the best solutions for your business needs

Outstanding Service

Full time, skilled service team employees available for start-up, maintenance and repair of your SMTCL machine

Contact us

Have any Questions?

Check our frequently asled question hope you get answer.

| Technical Parameter | ||||

|---|---|---|---|---|

| Item | Unit | VMC 850Q | VMC 1000Q | VMC 1100Q |

| Worktable | ||||

| Size | mm | 1000×500 | 1150×500 | 1300×610 |

| Max allowed loading | kg | 600 | 600 | 1000 |

| T slot size | mmxpcs | 18×5 | 18×5 | 18×5 |

| Machining range | ||||

| Max travel of table-X axis | mm | 850 | 1000 | 1100 |

| Max trave of slide-Y axis | mm | 500 | 500 | 620 |

| Max travel of spindle-Z axis | mm | 540 | 540 | 600 |

| Distance between spindle nose to worktable surface Max | mm | 660 | 660 | 720 |

| Distance between spindle nose to worktable surface Min | mm | 120 | 120 | 120 |

| Distance between spindle center to guideway base | mm | 640 | 640 | 743 |

| Spindle | ||||

| Taper (7:24) | BT40 | BT40 | BT40 | |

| Max speed | r/min | 10000 | 10000 | 10000 |

| Output torque | N.m | 35.8/70 (S2 15 Min) | 35.8/70 (S2 15 Min) | 52.5/95.5(S2 15 Min) |

| Motor power | kW | 7.5/11 | 7.5/11 | 11/15 |

| Drive type | Synchronous toothed belt | Synchronous toothed belt | Synchronous toothed belt | |

| Tools | ||||

| Tool holder model | MAS 403 BT40 | MAS 403 BT40 | MAS 403 BT40 | |

| Pull stud model | MAS 403 P40T-I | MAS 403 P40T-I | MAS 403 P40T-1 | |

| Feed | ||||

| Rapid traverse X axis | m/min | 48 | 48 | 48 |

| Rapid traverse Y axis | m/min | 48 | 48 | 48 |

| Rapid traverse Z axis | m/min | 48 | 48 | 48 |

| 3 axes moter power(X/Y/Z) | kW | 1.8/1.8/3 | 1.8/1.8/3 | 3/3/3 |

| 3 axes moter torque(X/Y/Z) | Nm | 11/11/20 | 11/11/20 | 20/20/20 |

| Feeding speed | mm/min | 1-20000 | 1-20000 | 1-20000 |

| Tool magazine | ||||

| Type | ATC with robot arm | ATC with robot arm | ATC with robot arm | |

| Mode | Nearest tool selection in bi-direction | Nearest tool selection in bi-direction | Nearest tool selection in bi-direction | |

| Capacity | Pcs | 24 | 24 | 24 |

| Max tool length | mm | 300 | 300 | 300 |

| Max tool weight | kg | 7 | 7 | 7 |

| Max too disk dia. Full | mm | Φ80 | Φ80 | Φ80 |

| Max too disk dia. Adjacent | mm | Φ150 | Φ150 | Φ150 |

| Tool change time (T-T) | S | 2.5 | 2.5 | 2.5 |

| The height between table to ground | mm | 900 | 900 | 950 |

| Machine weight | kg | 5100 | 5400 | 6200 |

| Total power capacity | KVA | 18 | 18 | 25 |

| Overall dimension (LxWxH) | mm | 2400x2975x2840 (Exclude chip conveyor) | 2700x2975x2840 (Exclude chip conveyor) | 2940x3450x3050 (Exclude chip conveyor) |

Main Body

Export to Excel

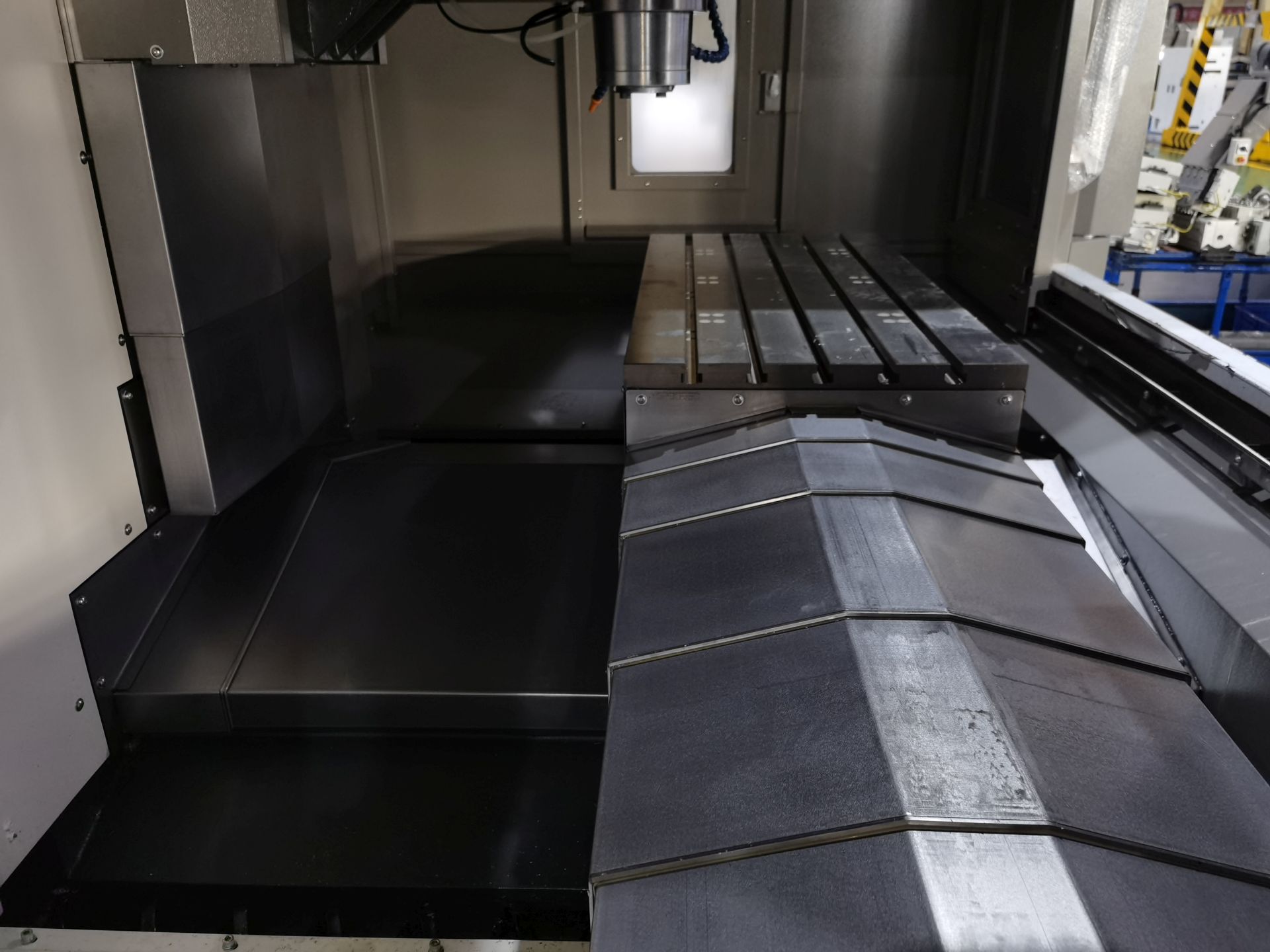

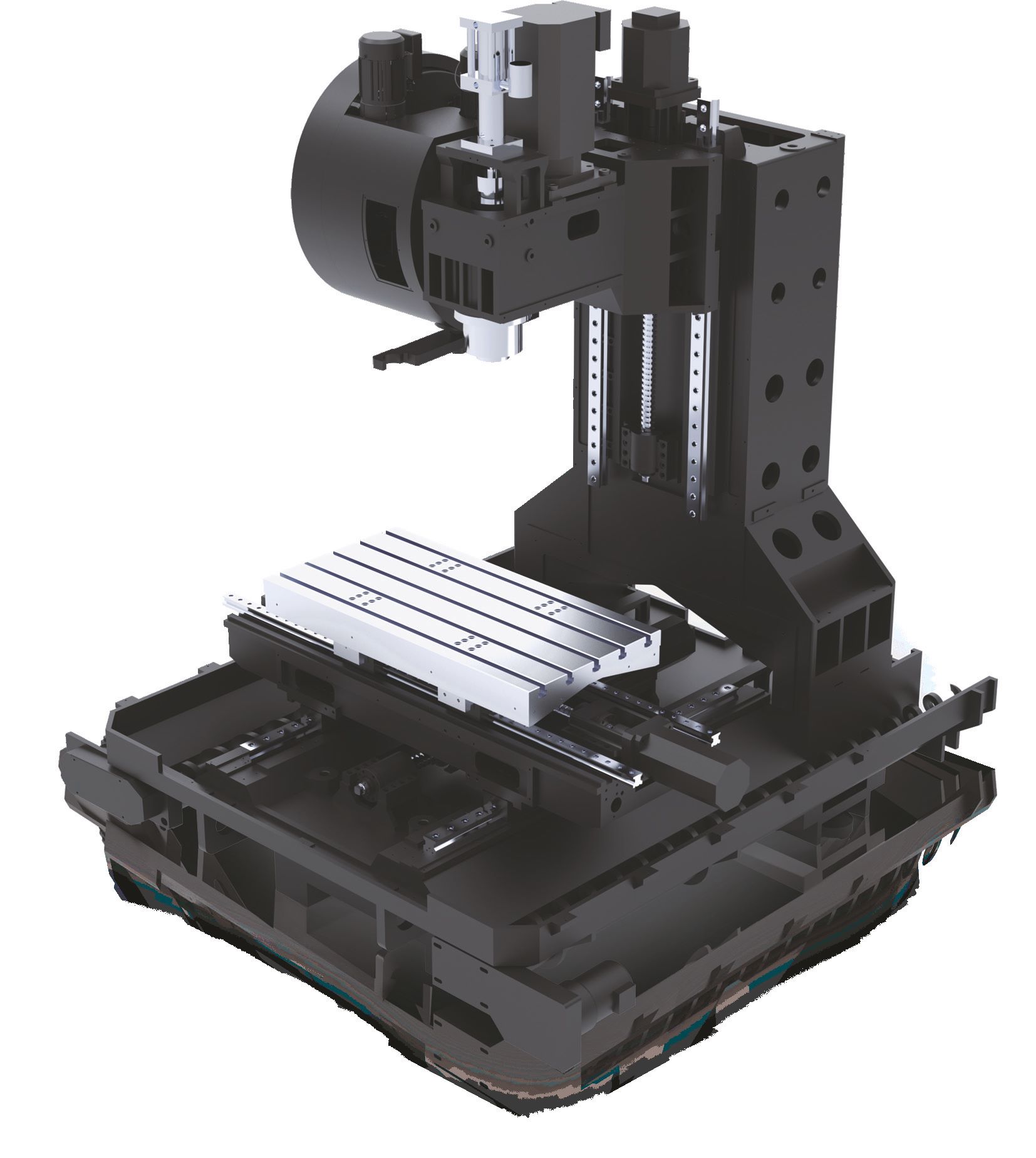

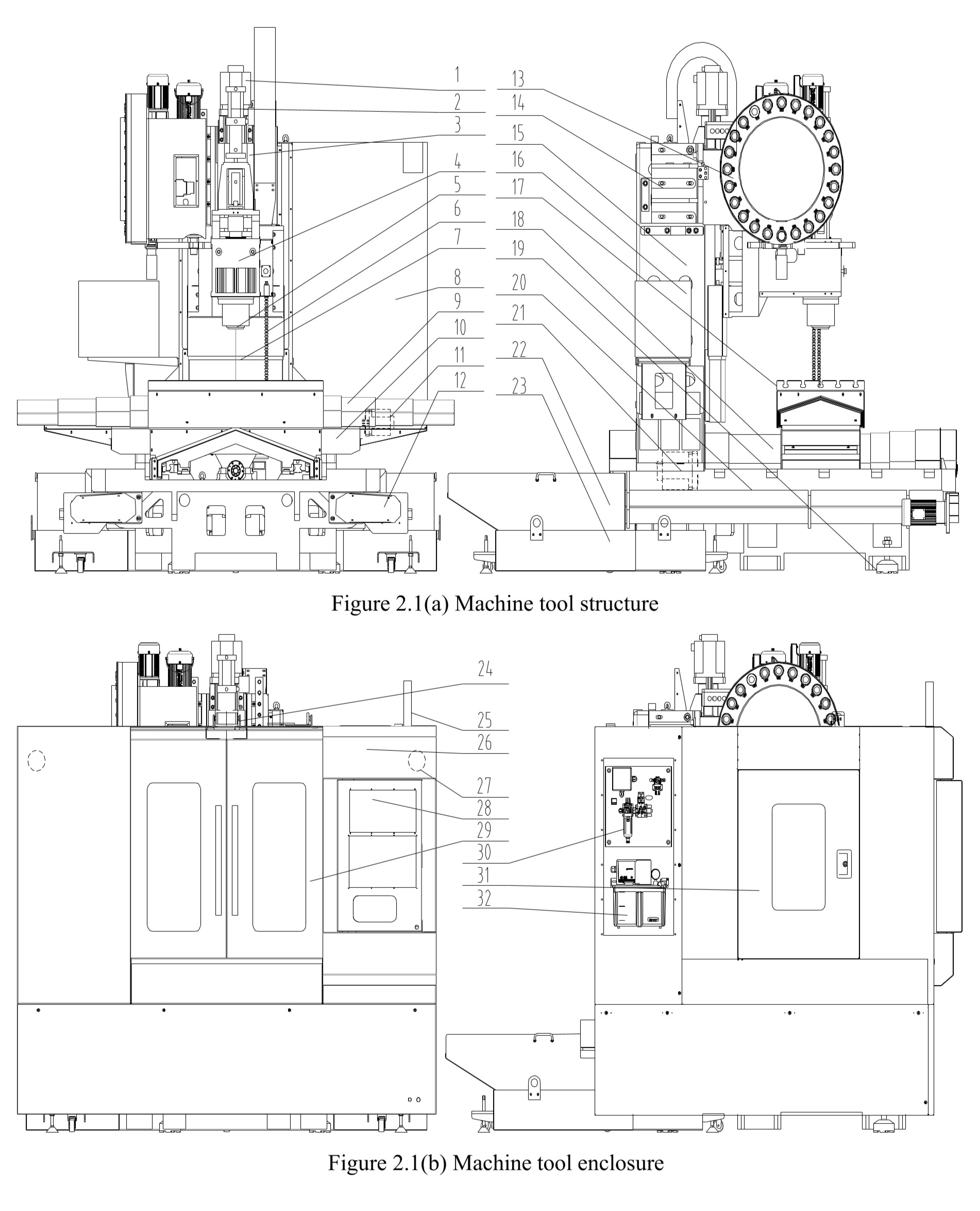

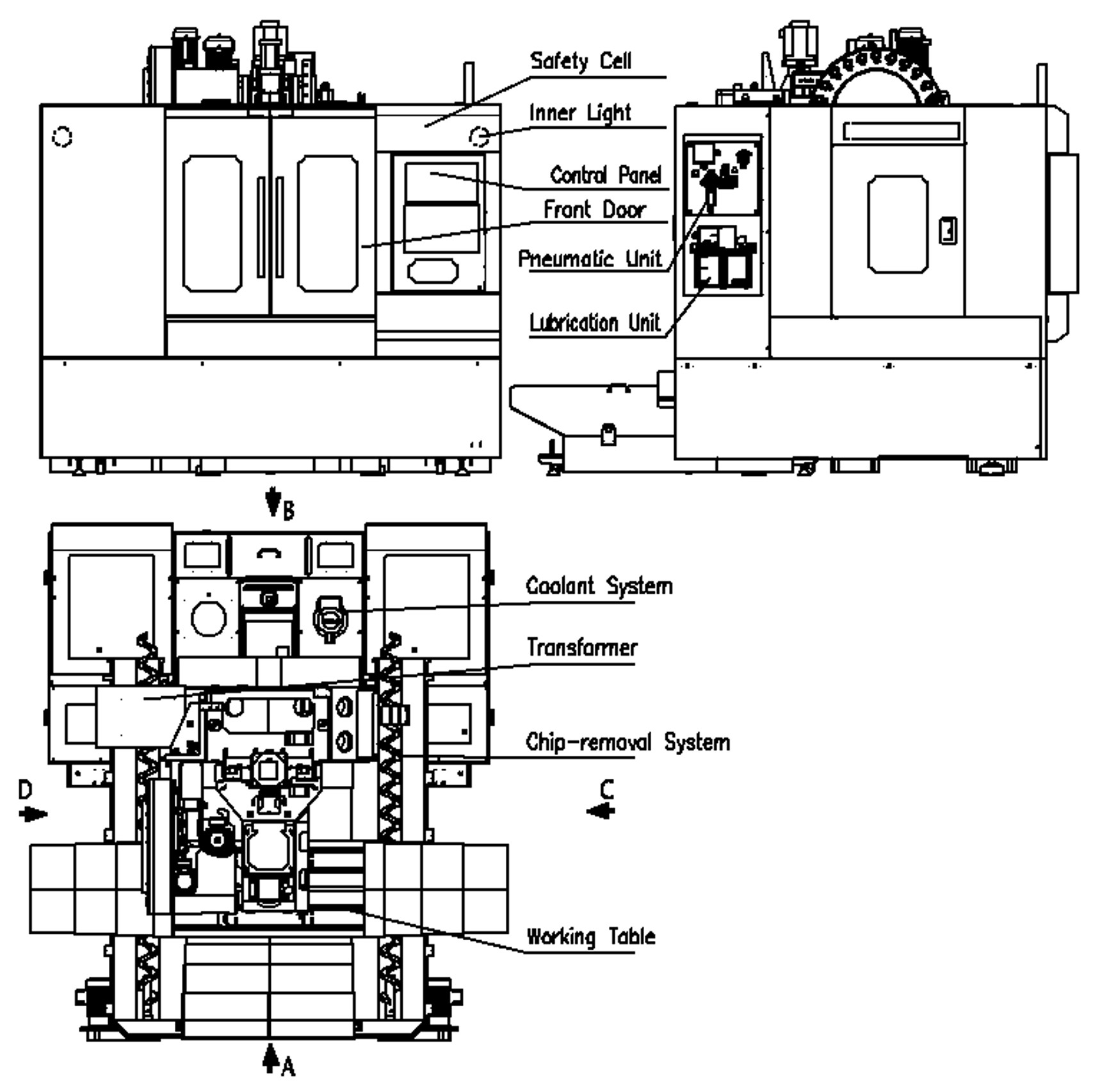

Export to Excel1 Z-axis servo motor 17 Working table 2 Pressure cylinder 18 Y-axis telescopic cover 3 Main motor 19 Foot parallels 4 Spindle box 20 Machine bed 5 Spindle 21 Y-axis servo motor 6 Adjustable coolant tube 22 Chip disposal tank 7 Z-axis telescopic cover 23 Water tank 8 Electrical cabinet 24 Front door lock 9 X-axis telescopic cover 25 3-color lamp 10 Slide 26 Safety cell 11 X-axis servo motor 27 Light 12 Helical chip removal mechanism 28 Operating box 13 Tool magazine 29 Front doors 14 Tool magazine holder 30 Pneumatic unit 15 Column 31 Side window 16 Transformer 32 Lubrication pump

| 1 | Z-axis servo motor | 17 | Working table |

|---|---|---|---|

| 2 | Pressure cylinder | 18 | Y-axis telescopic cover |

| 3 | Main motor | 19 | Foot parallels |

| 4 | Spindle box | 20 | Machine bed |

| 5 | Spindle | 21 | Y-axis servo motor |

| 6 | Adjustable coolant tube | 22 | Chip disposal tank |

| 7 | Z-axis telescopic cover | 23 | Water tank |

| 8 | Electrical cabinet | 24 | Front door lock |

| 9 | X-axis telescopic cover | 25 | 3-color lamp |

| 10 | Slide | 26 | Safety cell |

| 11 | X-axis servo motor | 27 | Light |

| 12 | Helical chip removal mechanism | 28 | Operating box |

| 13 | Tool magazine | 29 | Front doors |

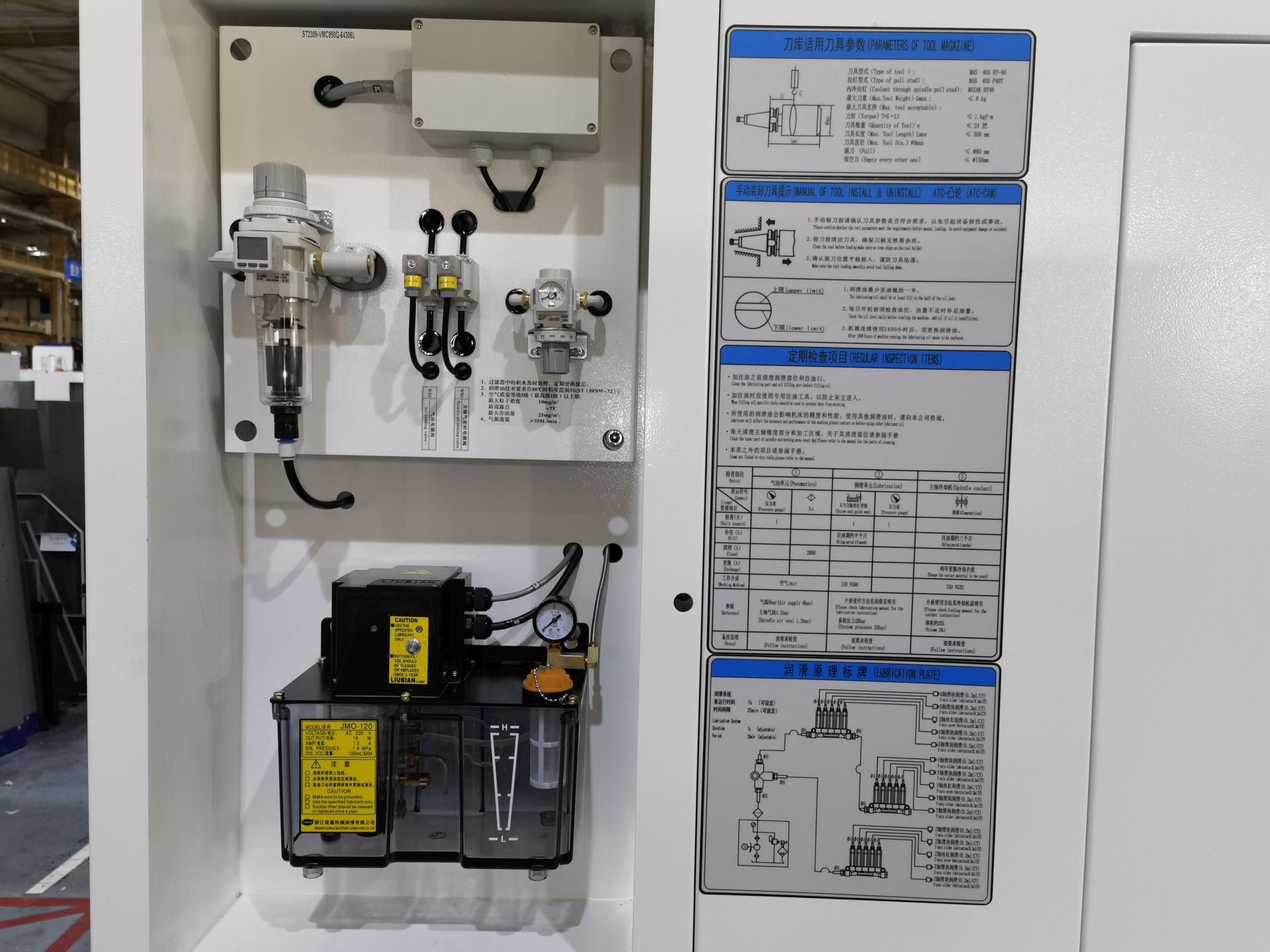

| 14 | Tool magazine holder | 30 | Pneumatic unit |

| 15 | Column | 31 | Side window |

| 16 | Transformer | 32 | Lubrication pump |

| No. | Operation | Position | Working Component | Illustration |

|---|---|---|---|---|

| 1 | Work piece change,clamp setup | Headstock | Control panel,working table | A |

| 2 | Programming, data input/output | Headstock | Control panel,working table | A |

| 3 | Power ON/OFF | Headstock/Tailstock | Control panel, rear of electrical cabinet | A,B |

| 4 | Tool change | Headstock | Tool magazine | A |

| 5 | Chip cleaning | Headstock | Inside safety cell, chip conveyor | A |

| 6 | Coolant filling | Tailstock | Coolant device | B |

| 7 | Fuse change | Tailstock | Inside electrical cabinet | B |

| 8 | Air pressure supply and shut off | Tailstock | Air device | B |

| 9 | Lubricant refilling | Tailstock | Lubrication device | B |

| 10 | LED change | Headstock | Inner light | A |

| 11 | Spindle motor cleaning | Headstock | Spindle motor | A |

- Headstock

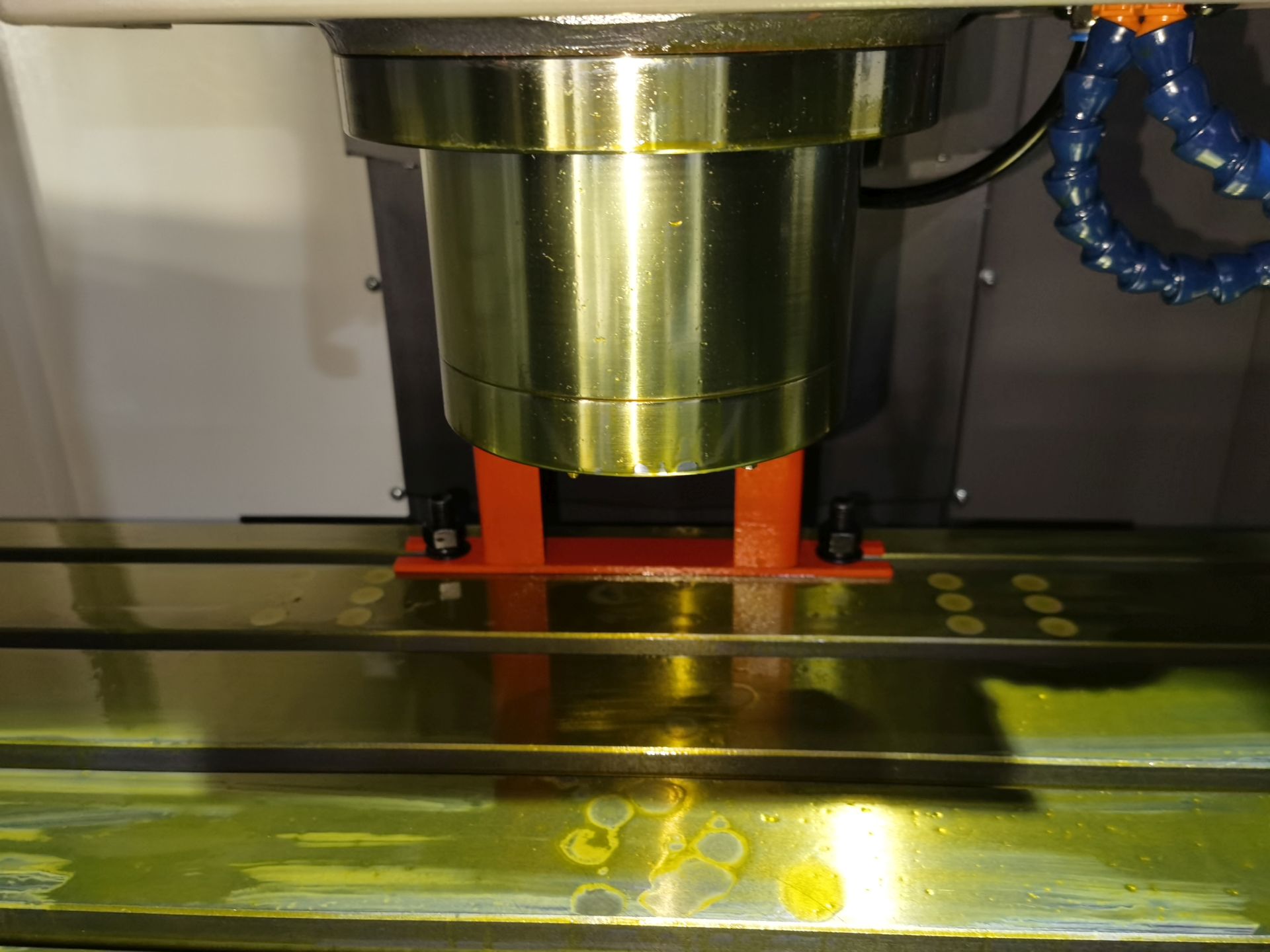

- High-precision integral spindle

- ATC+ large capacity tool magazine

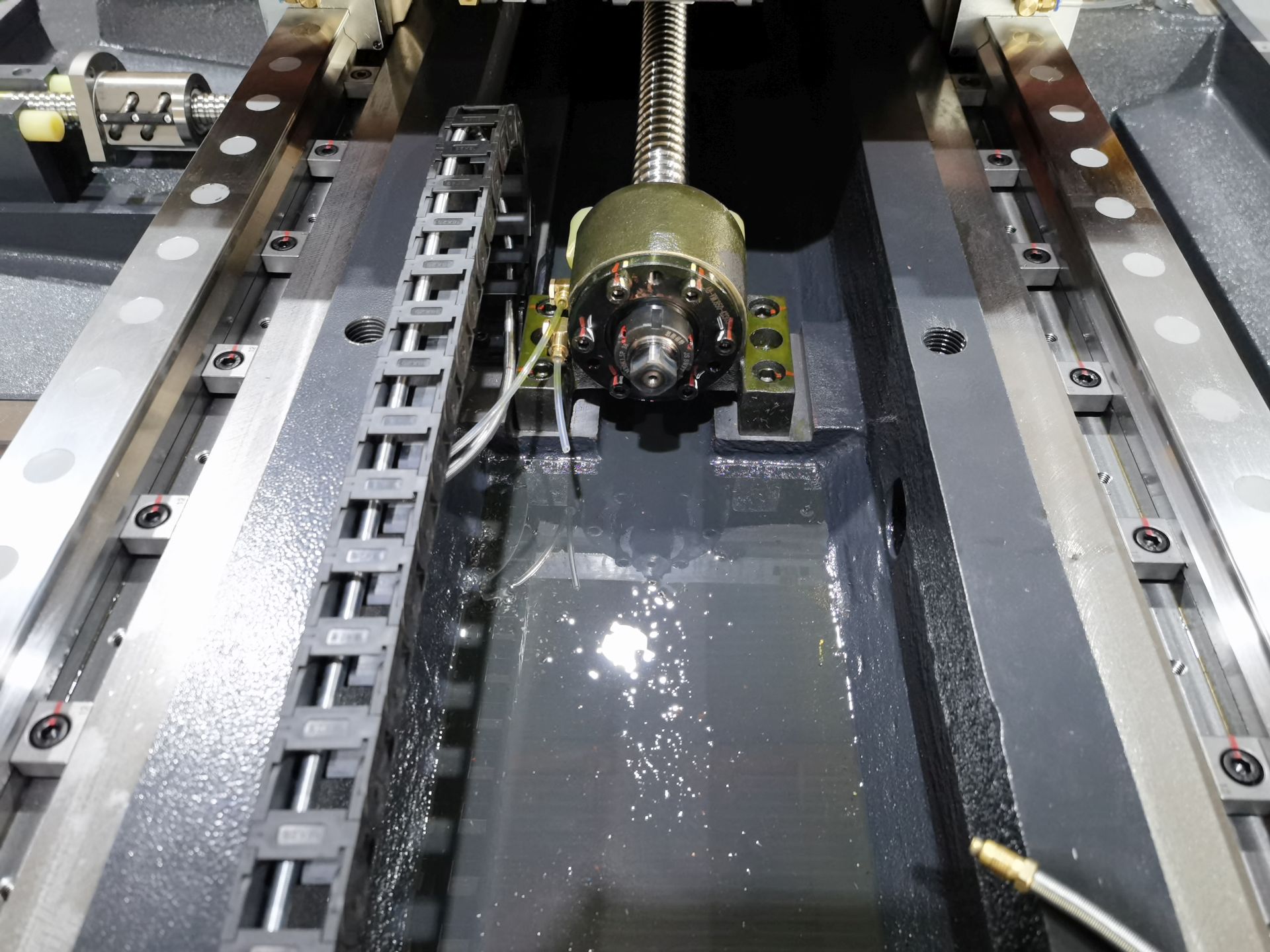

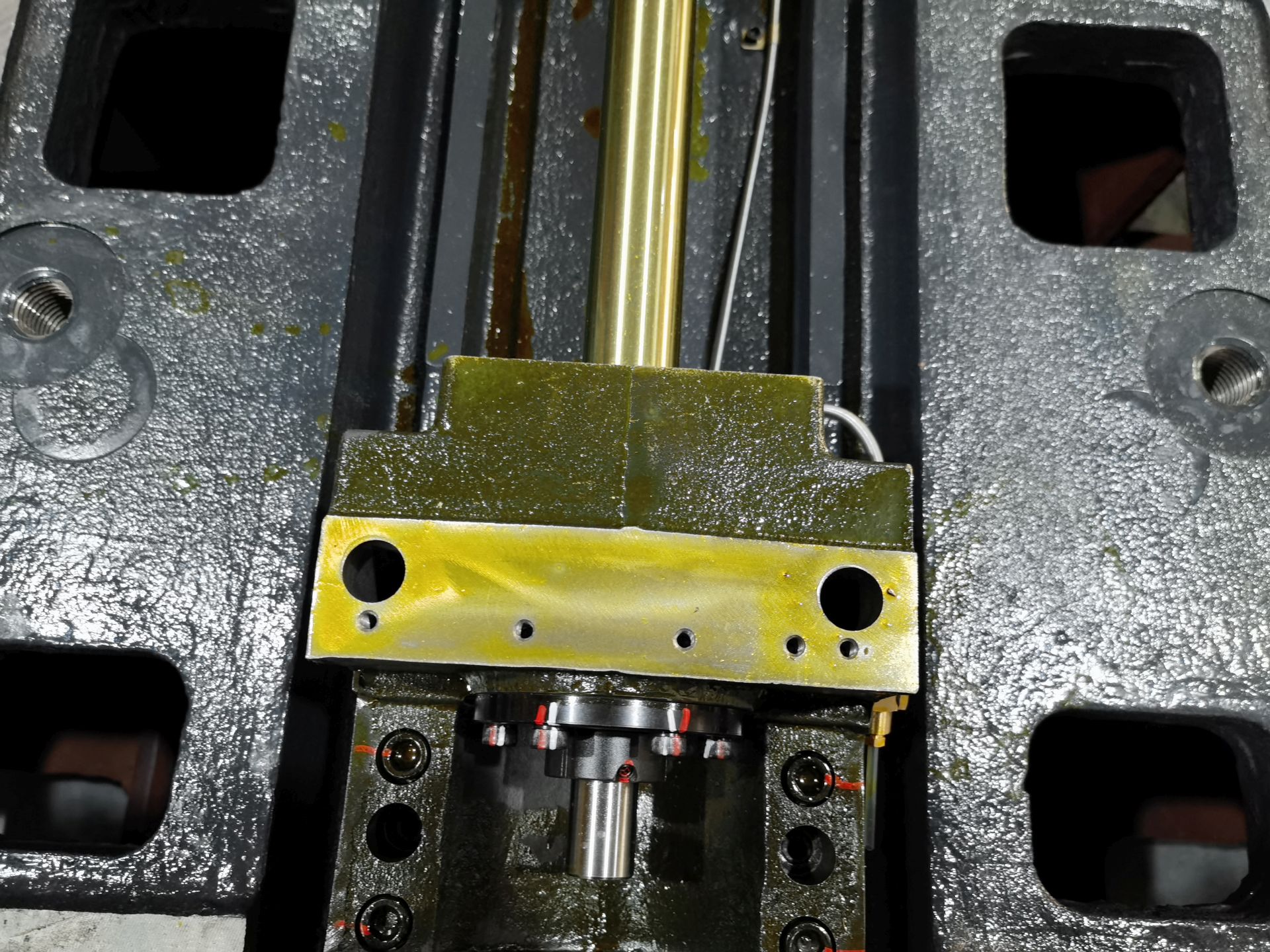

- Three-axis P-level roller guide way

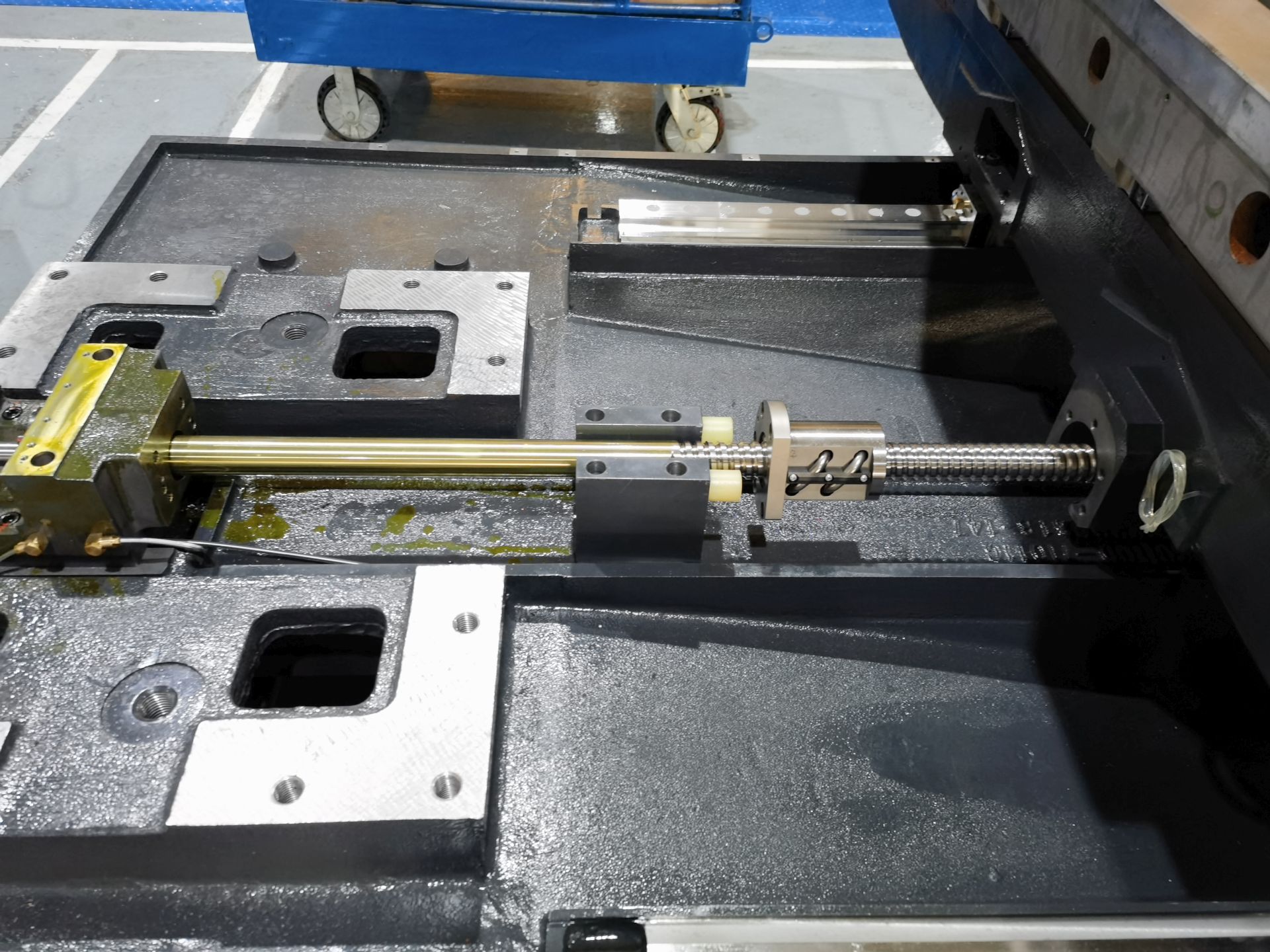

- C3 class pre-stretching leadscrew

- Lubrication Station

- Bearing

- Customizable CNC Operating System

- Worktable

- Lubrication station

- Large span herringbone column